Transforming Your Concepts Into Reality With HonHo Jewelry’s Expert Craftsmanship And Competitive Pricing

Send Your Custom Design Inquiry

Request For Full Catalog Now

We partner with renowned brands worldwide, delivering exceptional quality and craftsmanship in every piece

We transform your visionary designs into stunning, market-ready jewelry pieces

Collecting design information

CAD designs

Quotation

Mold Creating

Sampling&Production

Our comprehensive design-to-production process transforms your ideas into market-ready jewelry pieces with precision and artistry.

Explore our extensive customization options to create unique pieces for your brand

Choose from our premium materials and gemstones for your jewelry pieces

Add custom engravings and personalized designs to make your pieces unique

Select from a variety of surface finishes and textures for your jewelry

Explore our extensive range of plating options and colors

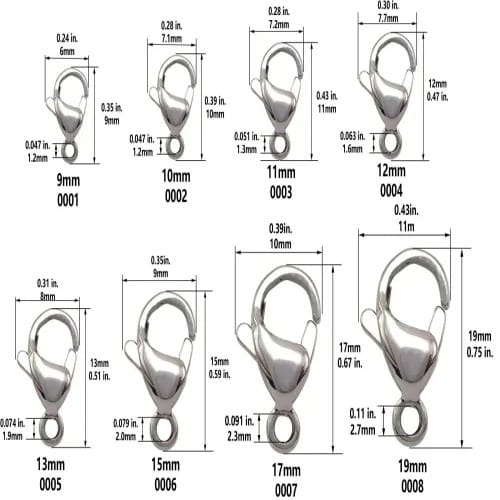

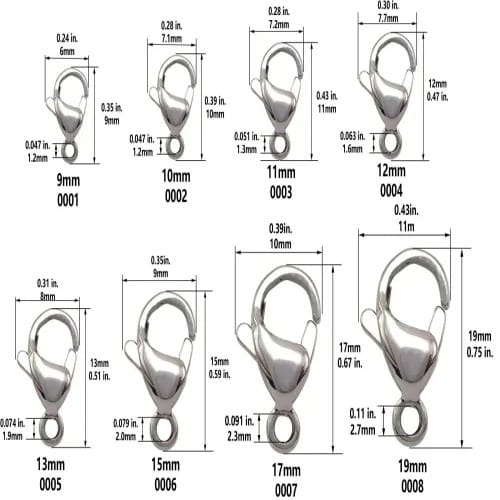

Choose from various clasps and chain styles for your jewelry pieces

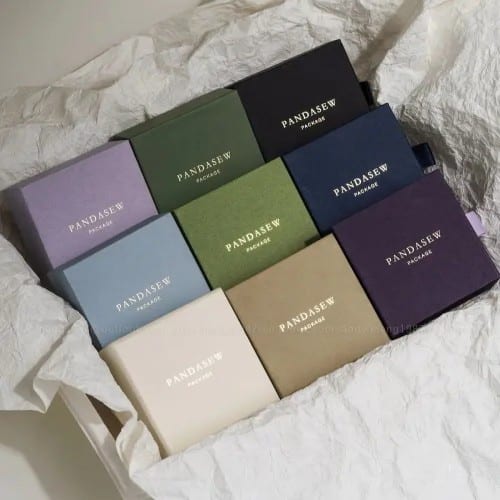

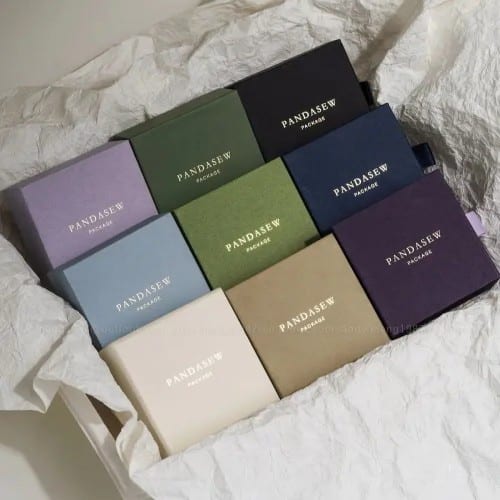

Complete your brand experience with custom packaging options

Choose from our premium materials and gemstones for your jewelry pieces

Add custom engravings and personalized designs to make your pieces unique

Select from a variety of surface finishes and textures for your jewelry

Explore our extensive range of plating options and colors

Choose from various clasps and chain styles for your jewelry pieces

Complete your brand experience with custom packaging options

We source only the finest materials to ensure the quality and longevity of all our jewelry pieces.

High-quality, durable and corrosion-resistant materials perfect for everyday wear.

Elegant golden tones with excellent malleability, perfect for intricate designs.

High-quality purity and luster, perfect for premium market positioning.

High-quality, durable and corrosion-resistant materials perfect for everyday wear.

Elegant golden tones with excellent malleability, perfect for intricate designs.

High-quality purity and luster, perfect for premium market positioning.

We source only the finest materials to ensure the quality and longevity of all our jewelry pieces.

Gold Vermeil is a premium gold plating process that applies a layer of 24K gold at least 2.5 microns thick over 925 sterling silver base.

Our Gold Vermeil process strictly follows international standards, ensuring layer thickness of 2.5-5.0 microns, with special sealing technology to extend jewelry lifespan.

Perfect for high-end jewelry collections, providing luxurious gold appearance with sterling silver value.

Gold Filled is a technique where a gold layer (at least 1/20 of total weight) is heat-bonded to a base metal, making it more durable than regular gold plating.

Our Gold Filled process uses 14K or 18K gold with heat-bonding technology ensuring the gold layer firmly adheres to the base metal without peeling or fading.

Ideal for high-quality jewelry requiring long-term gold shine retention, lasting 10-30 times longer than regular gold-plated products.

Ready To Start Your Vermail&Filled Jewelry Project

Are you struggling with these jewelry production issues? From material selection to cost control, our expert team is ready to provide you with customized solutions.

Jewelry pieces (especially bracelets and necklaces) breaking after very short periods of normal wear; chain breakage commonly occurring at connection points or clasp locations; “solder points” on welded bracelets coming loose; overall fragile feel, very thin chains that tangle or break easily.

Patented connection technology and enhanced welding processes; high-strength alloy materials; each connection point tested at 3x standard pull force; optimized chain thickness design balancing aesthetics and durability.

Gemstone-set jewelry pieces having stones that easily loosen or fall out; stones falling out of rings, earrings, or pendants after short periods of wear; questionable setting craftsmanship; poor gemstone quality.

Patented setting techniques, each stone undergoes multiple fixation tests ensuring long-term stability; high-quality cubic zirconia and semi-precious stones; each set product undergoes ultrasonic vibration testing to ensure stone stability.

Plating not lasting, gold-plated jewelry quickly fading, oxidizing, darkening, or developing spots; different materials being affected; jewelry causing skin discoloration.

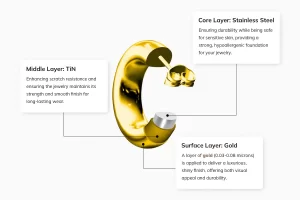

Advanced PVD plating technology + titanium nitride (TiN) protective layer ensuring 2+ years of color retention; multi-layer plating process enhancing surface durability; lead-free and nickel-free formulations preventing skin allergies and discoloration.

Actual quality of products not matching their price point; materials looking poor, gold tones appearing unnatural; stones lacking brilliance; jewelry feeling very light without expected substance.

Strict quality control system ensuring consistency in bulk production; quality material selection ensuring appropriate weight and feel; professional plating processes delivering natural, premium metal luster.

Jewelry pieces easily deforming, especially rings; surfaces easily scratching even with normal wear.

Higher hardness alloy materials; surface hardening treatment technology; special anti-scratch coating protection; each product tested for hardness and bending resistance.

Sizes not matching images; detail processing issues; attachment problems; chain holes too small; asymmetry or flaws.

Precise size control and standardization; professional detail processing workflows; comprehensive accessory inspection system; standardized chain hole design; 100% manual inspection ensuring no obvious flaws.

Jewelry pieces (especially bracelets and necklaces) breaking after very short periods of normal wear; chain breakage commonly occurring at connection points or clasp locations; “solder points” on welded bracelets coming loose; overall fragile feel, very thin chains that tangle or break easily.

Patented connection technology and enhanced welding processes; high-strength alloy materials; each connection point tested at 3x standard pull force; optimized chain thickness design balancing aesthetics and durability.

Gemstone-set jewelry pieces having stones that easily loosen or fall out; stones falling out of rings, earrings, or pendants after short periods of wear; questionable setting craftsmanship; poor gemstone quality.

Patented setting techniques, each stone undergoes multiple fixation tests ensuring long-term stability; high-quality cubic zirconia and semi-precious stones; each set product undergoes ultrasonic vibration testing to ensure stone stability.

Plating not lasting, gold-plated jewelry quickly fading, oxidizing, darkening, or developing spots; different materials being affected; jewelry causing skin discoloration.

Advanced PVD plating technology + titanium nitride (TiN) protective layer ensuring 2+ years of color retention; multi-layer plating process enhancing surface durability; lead-free and nickel-free formulations preventing skin allergies and discoloration.

Actual quality of products not matching their price point; materials looking poor, gold tones appearing unnatural; stones lacking brilliance; jewelry feeling very light without expected substance.

Strict quality control system ensuring consistency in bulk production; quality material selection ensuring appropriate weight and feel; professional plating processes delivering natural, premium metal luster.

Jewelry pieces easily deforming, especially rings; surfaces easily scratching even with normal wear.

Higher hardness alloy materials; surface hardening treatment technology; special anti-scratch coating protection; each product tested for hardness and bending resistance.

Sizes not matching images; detail processing issues; attachment problems; chain holes too small; asymmetry or flaws.

Precise size control and standardization; professional detail processing workflows; comprehensive accessory inspection system; standardized chain hole design; 100% manual inspection ensuring no obvious flaws.

Our unique advantages set us apart as your ideal jewelry manufacturing partner

Advanced PVD technology with customizable thickness (0.03-2.5 microns)

Titanium nitride (TiN) protective layer extends color retention by 2+ year

Network of 10 specialized manufacturers, 5,000+ unique components

15+ years jewelry manufacturing experience, craftsmen averaging 10+ years expertise

12 refinishing techniques, 100+ unique metal finishes

Approximately 150 new designs every season

https://www.youtube.com/watch?v=oKevfmbM7wQ

Our jewelry withstands accelerated corrosion testing, simulating 2 years of daily wear. 99.2% quality pass rate demonstrates exceptional durability.

100% Shine

99.2% Retention

Our proprietary TiN protective layer creates a molecular barrier that prevents oxygen and moisture from reaching the metal surface, extending color retention by 2+ year compared to competitors.

| Feature | Standard Electroplating | Basic PVD | HonHo PVD Technology |

|---|---|---|---|

| Color Retention | 3-6 months | 1 year | 2+ years |

| Waterproof | No | Limited | Yes |

| Protective Layer | None | Basic | TiN Enhanced |

| Scratch Resistance | Low | Medium | High |

Founded in 2010, Dongguan HonHo Jewelry specializes in high-quality waterproof and non-tarnish jewelry manufacturing. With over 3,000 square meters of modern production facilities and a team of 50+ professional craftsmen and designers, we are a leading ODM/OEM manufacturer providing over 2 million quality jewelry pieces annually to brands across 50+ countries. Our mission is to help each brand stand out in the competitive market through continuous innovation and excellent craftsmanship.

Choosing Honho as your jewelry manufacturer means partnering with a leader in innovation and quality. We are committed to your success in the competitive jewelry market through professional service and exceptional craftsmanship.

15 years of refined craftsmanship in fashion jewelry production, serving over 500 global brands with premium OEM/ODM services.

Our unique advantage: Advanced PVD plating equipment ensuring durable gold, rose gold, and platinum finishes that creates waterproof and anti-tarnish jewelry.

From design to sample in just 7-20 days, with free CAD/3D rendering services from our professional design team. Over 500 new designs developed annually.

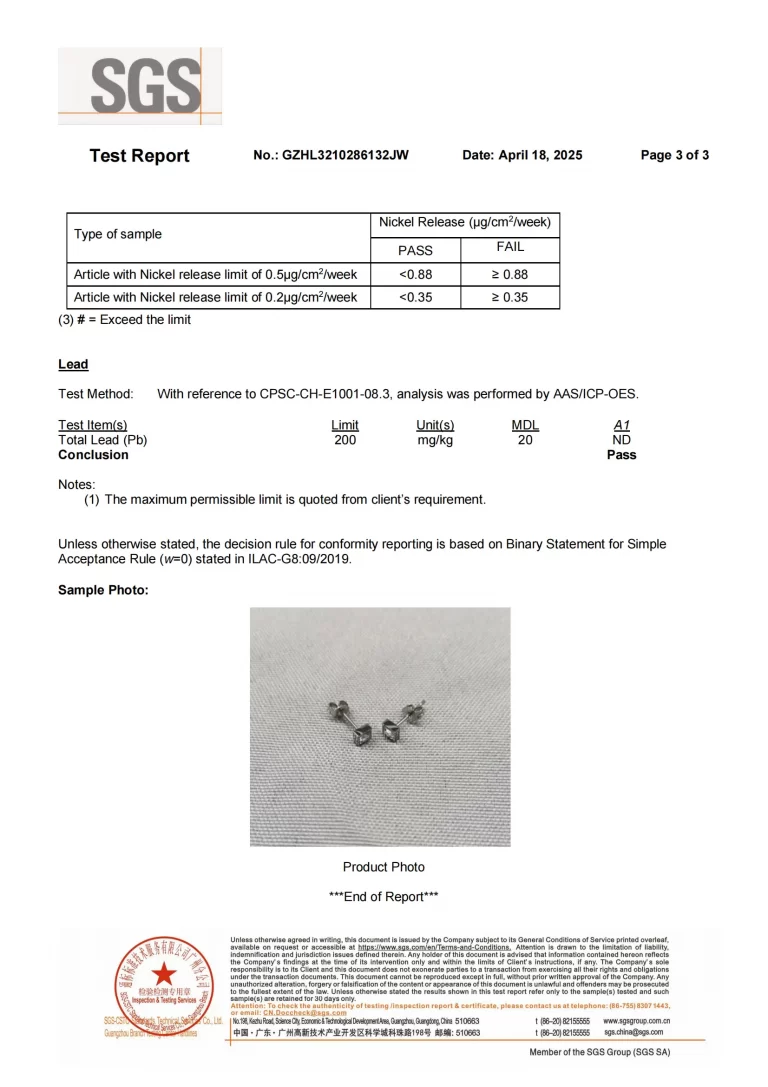

100% quality inspection with defect rates below 0.5%. All products meet EU/US standards with lead-free and nickel-free manufacturing processes.

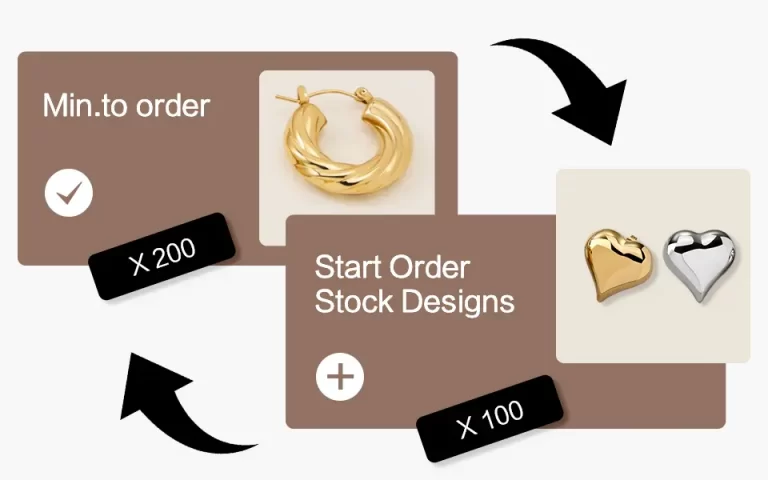

Minimum order quantity as low as 30 pieces per style, supporting small-batch customization to help emerging brands minimize inventory risks.

Dispatch within 48 hours via DHL/FedEx/UPS international express services. Average delivery cycle of 15 days with 99% on-time delivery rate.

Explore our newest jewelry designs, showcasing our craftsmanship and innovation

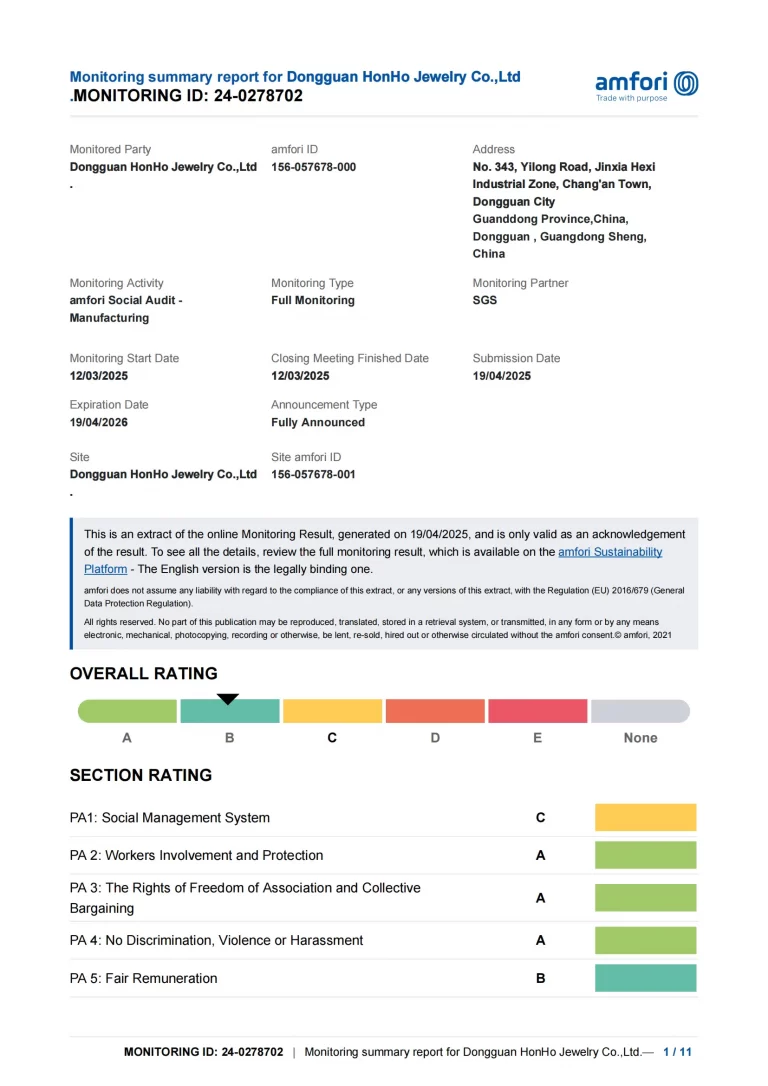

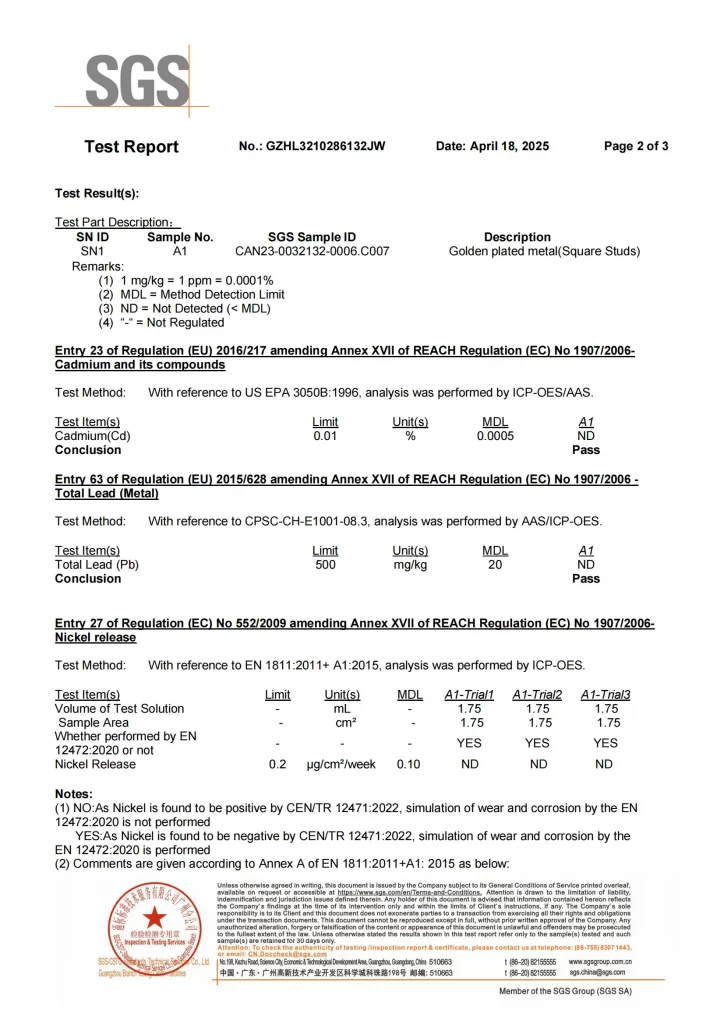

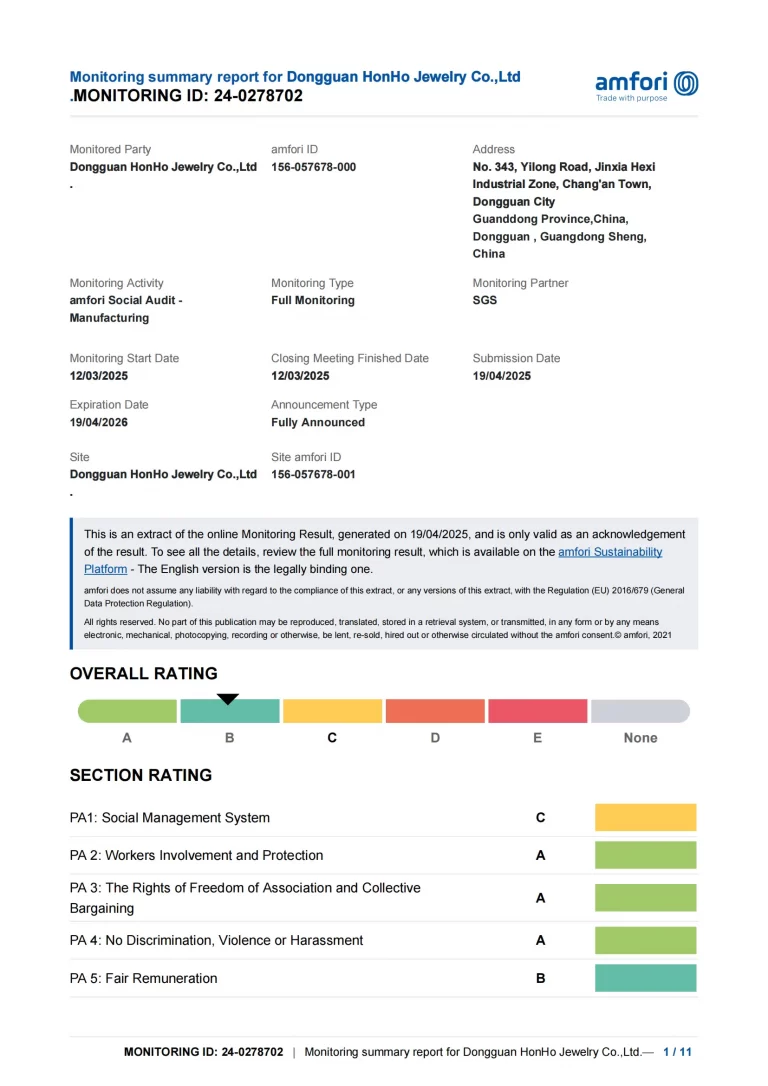

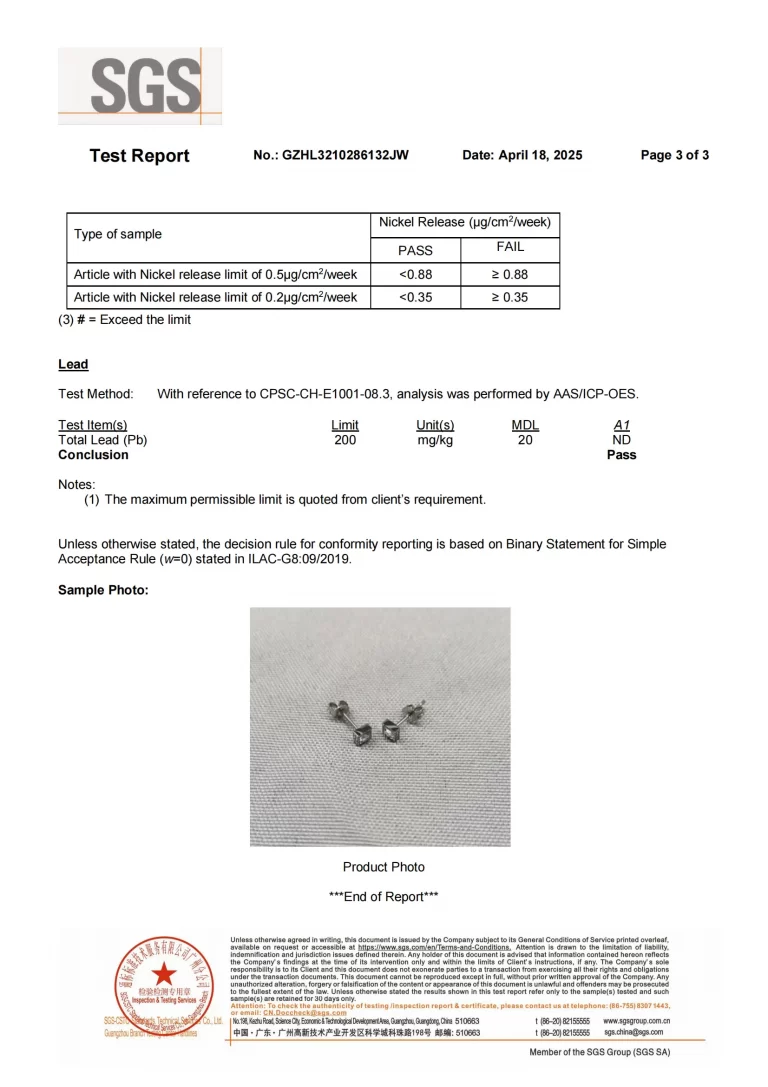

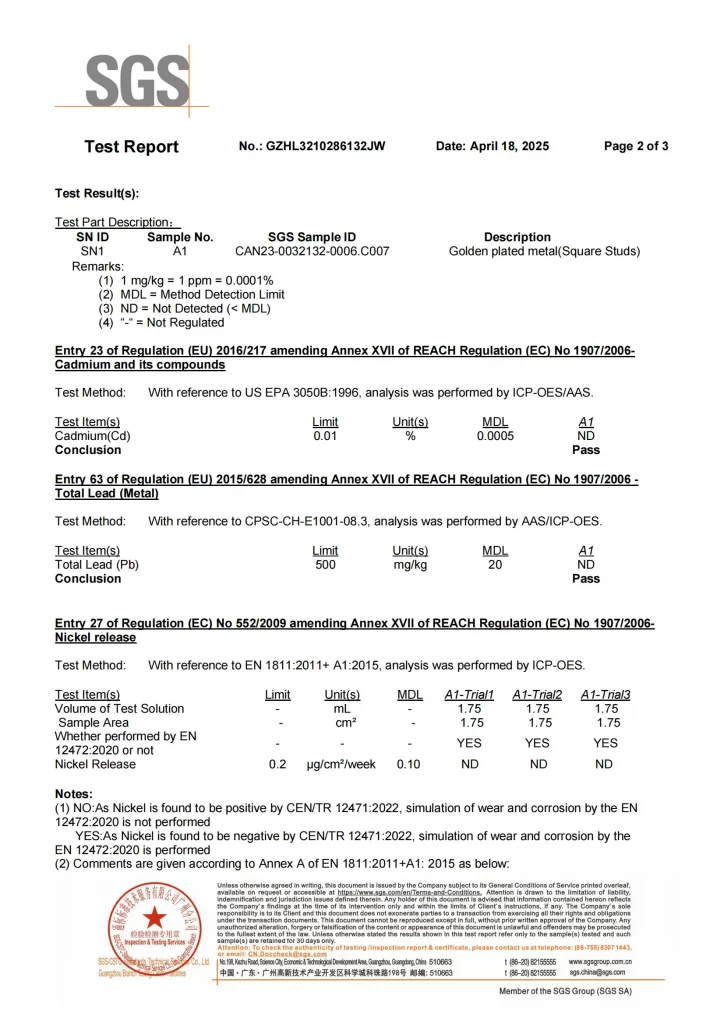

Our commitment to excellence is backed by internationally recognized certifications and rigorous quality testing

Ensuring social responsibility and working conditions meet international standards

Certification for environmentally sustainable material usage, ensuring eco-friendly production processes

Third-party authoritative testing ensuring product safety and quality

Third-party authoritative testing ensuring product safety and quality

Ensuring social responsibility and working conditions meet international standards

Certification for environmentally sustainable material usage, ensuring eco-friendly production processes

Third-party authoritative testing ensuring product safety and quality

Third-party authoritative testing ensuring product safety and quality

https://www.youtube.com/watch?v=iHycgflrcBU

Quality that stands the test of time… and water!

Our jewelry doesn’t just look beautiful – it’s built to last! Immersed in water for days, weeks, even months, and still shining bright.

Pass rate in accelerated corrosion testing

Exceeds industry standard pull force

Average Vickers hardness rating

Hypoallergenic material safety

Tailored manufacturing solutions for different business models in the jewelry industry

Perfect solutions for e-commerce sellers across all major platforms

Learn how we can help your business

We support influencers in building their own jewelry brands with comprehensive services

Learn how we can help your business

Reliable supply chain solutions for wholesalers requiring consistent quality and competitive pricing

Learn how we can help your business

Full OEM/ODM capabilities for established and emerging jewelry brands

Learn how we can help your business

Support for physical retailers with ready-to-sell collections and custom displays

Learn how we can help your business

Perfect solutions for e-commerce sellers across all major platforms

Learn how we can help your business

We support influencers in building their own jewelry brands with comprehensive services

Learn how we can help your business

Reliable supply chain solutions for wholesalers requiring consistent quality and competitive pricing

Learn how we can help your business

Full OEM/ODM capabilities for established and emerging jewelry brands

Learn how we can help your business

Support for physical retailers with ready-to-sell collections and custom displays

Learn how we can help your business

Hear from brands who have experienced the HonHo Jewelry difference.

https://www.youtube.com/watch?v=7JzqkfEc0tI&list=PLQg4yjGXQrPYAHE8m0GsSdFksHbgCkBHf

Find answers to common questions about our products, services, and processes.

Our Minimum Order Quantity (MOQ) varies by product type. For in-stock products, it’s typically 10-50 pieces per style, while custom products require 30-100 pieces per style. We also offer small batch sample orders to help you test market response.

Standard products have a delivery time of 15-20 days. Custom designs typically require 25-35 days, including design confirmation (3-5 days), sample production (10-25 days), and bulk production (15-30 days). Rush services are available for urgent orders.

We offer comprehensive customization services including material selection, size adjustments, surface treatments, plating colors, logo engraving, gemstone selection and setting, packaging design, and more. Our design team can develop 3D models and samples from your sketches or concepts.

We implement a strict quality control system including raw material inspection, production process checks, and 100% finished product inspection. Every product undergoes salt spray testing, tensile strength testing, and wear resistance testing to ensure compliance with international standards. We provide quality guarantees and after-sales support.

We use advanced PVD plating technology and proprietary titanium nitride (TiN) protective layer, giving our products excellent waterproof and tarnish-resistant properties. Our products undergo 24-hour salt spray tests (equivalent to 2 years of daily wear) to ensure long-term retention of shine and color.

We sign strict Non-Disclosure Agreements (NDAs), implement encrypted storage of design files, and limit access to production areas. We respect and protect our clients’ intellectual property, ensuring your designs won’t be copied or leaked.

Yes, we provide sample services. Existing product samples cost 50% of the normal price, while custom samples are charged based on complexity. Sample fees can be partially or fully credited when bulk orders are confirmed. Sample production typically takes 15-25 business days.

We accept T/T (wire transfer), PayPal, Western Union, and credit card payments. Standard terms are 30% deposit, with 70% due before shipment. More flexible payment terms are available for long-term partners.

We provide comprehensive after-sales service. If quality issues are found, please provide photos and detailed descriptions, and we’ll respond within 24 hours. Depending on the situation, we offer free replacements, repairs, or refunds. Replacements or discounts can also be arranged for the next order.

Yes, our professional design team can assist in developing complete product lines. From market trend analysis and concept design to 3D modeling and sample production, we offer end-to-end services. We develop approximately 150 new designs each season, which can be customized according to your brand positioning and target market.

Our Minimum Order Quantity (MOQ) varies by product type. For in-stock products, it’s typically 10-50 pieces per style, while custom products require 30-100 pieces per style. We also offer small batch sample orders to help you test market response.

Standard products have a delivery time of 15-20 days. Custom designs typically require 25-35 days, including design confirmation (3-5 days), sample production (10-25 days), and bulk production (15-30 days). Rush services are available for urgent orders.

We offer comprehensive customization services including material selection, size adjustments, surface treatments, plating colors, logo engraving, gemstone selection and setting, packaging design, and more. Our design team can develop 3D models and samples from your sketches or concepts.

We implement a strict quality control system including raw material inspection, production process checks, and 100% finished product inspection. Every product undergoes salt spray testing, tensile strength testing, and wear resistance testing to ensure compliance with international standards. We provide quality guarantees and after-sales support.

We use advanced PVD plating technology and proprietary titanium nitride (TiN) protective layer, giving our products excellent waterproof and tarnish-resistant properties. Our products undergo 24-hour salt spray tests (equivalent to 2 years of daily wear) to ensure long-term retention of shine and color.

We sign strict Non-Disclosure Agreements (NDAs), implement encrypted storage of design files, and limit access to production areas. We respect and protect our clients’ intellectual property, ensuring your designs won’t be copied or leaked.

Yes, we provide sample services. Existing product samples cost 50% of the normal price, while custom samples are charged based on complexity. Sample fees can be partially or fully credited when bulk orders are confirmed. Sample production typically takes 15-25 business days.

We accept T/T (wire transfer), PayPal, Western Union, and credit card payments. Standard terms are 30% deposit, with 70% due before shipment. More flexible payment terms are available for long-term partners.

We provide comprehensive after-sales service. If quality issues are found, please provide photos and detailed descriptions, and we’ll respond within 24 hours. Depending on the situation, we offer free replacements, repairs, or refunds. Replacements or discounts can also be arranged for the next order.

Yes, our professional design team can assist in developing complete product lines. From market trend analysis and concept design to 3D modeling and sample production, we offer end-to-end services. We develop approximately 150 new designs each season, which can be customized according to your brand positioning and target market.

Ready to elevate your jewelry line? Contact us to discuss your project requirements