Sustainable Jewelry Manufacturing: Ethical Practices & Key Players

Key Takeaways

- Jewelry manufacturing in the United States combines old world craftsmanship with cutting edge technology and a synergistic relationship between product designers, manufacturers, and jewelry retailers.

- In the context of the jewelry market, ethical sourcing and sustainability practices are becoming more prevalent with every shift, directly influencing consumer trust and brand reputation.

- Leading China jewelry manufacturers excel due to their superior craftsmanship, intense quality control and dedication to responsible business practices.

- Innovation through customization Customization options, along with flexible services, enable manufacturers to address the unique needs of various clients and adapt quickly to changing market trends.

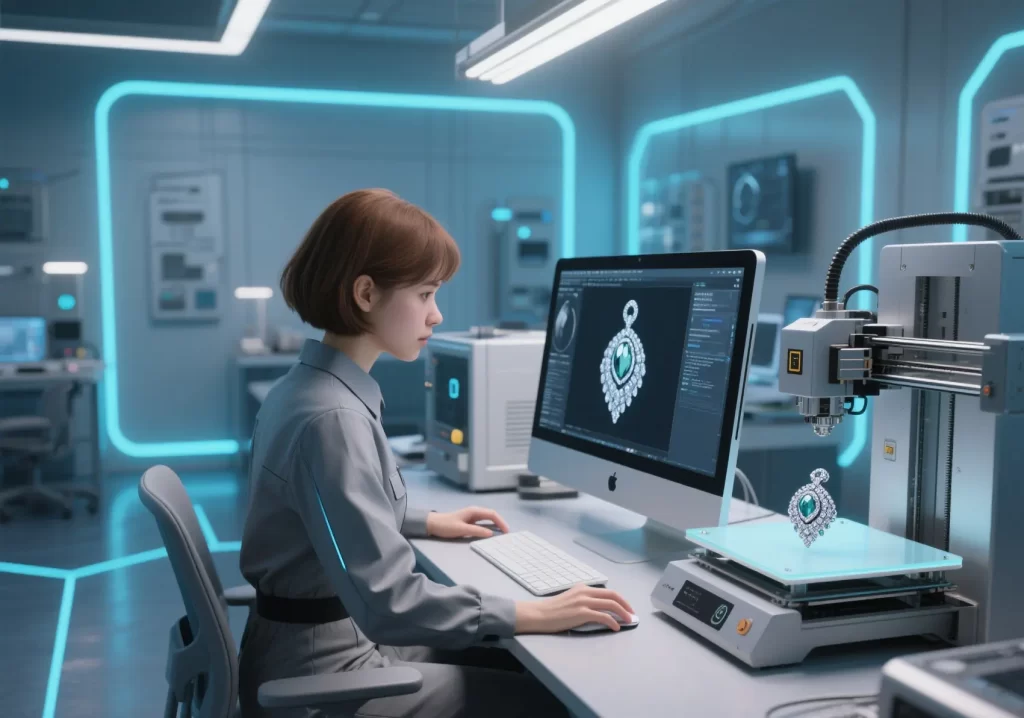

- Embracing new technologies such as CAD and 3D printing is necessary. It increases productivity, improves accuracy, and helps you stay competitive in today’s jewelry manufacturing environment!

- Fostering partnerships and keeping communication lines open throughout the supply chain is key to maintaining efficient operations and uniform product quality.

Jewelry manufacturing companies work closely with your designs to customize, craft, and create exceptional production jewelry. They serve retailers and manufacturers alike, brands and non-brands across the United States. Engaging in complex manufacturing processes, these companies fashion metals and gems from gold and silver to diamonds and colored stones.

Many focus on custom jobs, small-batch runs, or mass production to meet the needs of local retailers and national chains. Some are full-service, giving you everything from design sketches to final polish. Others work only on one stage of the production process, like casting or setting.

Today, many run advanced manufacturing technology in tandem with experienced bench jewelers to meet current demands in style and quality. The following sections explain the processes and practices of jewelry manufacturers and the services they offer. They further identify what distinguishes America’s best firms from their peers.

What Jewelry Manufacturers Do

Jewelry manufacturers, including responsible jewelry suppliers, take a project from initial design to final production.

Development

The jewelry-making process begins with design, where creativity plays a crucial role. Sometimes the inspiration comes from a suggestion by a client, while other times it emerges from a dedicated creator. Responsible jewelry manufacturers take feedback, blue-sky designs, and incredible ideas, helping everyone see what’s possible. They make modifications to the design along the way to fit the customer’s vision, particularly when it involves custom jewelry manufacturing.

Partnership is essential in this realm, especially for custom orders or one-of-a-kind creations like an engagement ring. Once the design is finalized, skilled artisans bring the design to life. Their hands move to hammer, form, solder, and polish metals, set stones, and cleanly finish rough edges, ensuring that each piece reflects quality fine craftsmanship.

Workshops serve as spaces for all kinds of work, including electroplating, which deposits thin layers of metal onto jewelry to enhance luster or prevent tarnishing. Gem cutters or lapidaries shape and fit meaningful gemstones into their mountings, ensuring a perfect engagement ring.

Beyond just casting, there are teams for mold making, polishing and setting. Each step requires precision to ensure the best quality possible. A few of these companies have gained their reputation by specializing in stainless steel, brass, and 925 silver jewelry.

HonHo Jewelry Manufacturer from China is one of them, known for their commitment to responsible jewelry practices. They offer a wide variety of waterproof, non-tarnish, gold vermeil, and gold-filled jewelry. Their talented design team is capable of producing everything from elegant traditional pieces to flashy, fashion-forward creations.

Types of Manufacturers

Jewelry manufacturers may be artisans, boutique custom shops, or international mass producers. Some produce millions of pieces each year, while others prefer to work in limited editions. Price and quality are all over the place.

Competitors that take shortcuts might be able to provide cheaper prices, but the quality and longevity of their work will suffer. Reputable manufacturers adhere to rigorous standards of quality control, frequently obtaining certifications such as ISO 9001 or BSCI.

They are conscientious in maintaining the highest standards and only use ethical sourcing for all materials.

Inside the China Jewelry Supply Chain

The US jewelry supply chain is a complicated system, formed by an intricate network of local and global connections. It carries finished jewelry down a line of skilled hands, then allows manufacturers to get their pieces and collections into retail display cases. Every stage requires trust, defined roles, and explicit timing.

The table below breaks down the main steps:

|

Stage |

What Happens |

Key Players |

|---|---|---|

|

Raw Materials |

Extracting metals and gems, grading materials |

Miners, suppliers |

|

Manufacturing |

Shaping, setting, and finishing jewelry pieces |

Artisans, factories |

|

Retail |

Selling finished pieces to the public |

Wholesalers, retailers |

This point in local sourcing is particularly important for US brands. It shortens lead times and allows companies to inspect quality more frequently. Collaborating with local makers enables brands to be more agile when it comes to keeping pace with market trends and developing new designs.

From Raw Metals to Retail

Jewelry begins with raw metals such as gold, silver, or platinum. These precious metals get mined, sorted, and refined before heading to skilled artisans. Designing and producing jewelry in China usually involves tight collaboration between in-house teams and go-to manufacturers.

HonHo Jewelry Manufacturer is the leader in stainless steel jewelry and 925 silver jewelry. They illustrate how custom alternatives and advanced innovation, including 3D printing, are reshaping the industry. Finally, wholesalers play a role in getting finished goods to retailers.

Sourcing Gems and Materials Ethically

By now you know that ethical sourcing is not just a trend. This guides brands to choose suppliers that will pay fair wages and operate safely. When a brand uses recycled gold or lab-grown gems, this builds an immediate level of trust and sets the brand apart.

Consumers increasingly demand transparency on the origin of their pieces, pushing brands to adopt traceability resources such as blockchain technology.

The Manufacturer’s Crucial Role

Beyond that, responsible jewelry manufacturers play a critical role in linking designers and stores together. They inspect each item for craftsmanship and consistency, ensuring adherence to American safety and trade regulations. Clear communications allow issues to be addressed early, keeping the entire jewelry business supply chain flowing.

Key Traits of Top China Jewelry Manufacturers

The most successful China makers in the jewelry business distinguish themselves by combining craftsmanship, integrity, and innovation. They balance high-end old-school craft with new tech, including custom jewelry manufacturing, all the while looking down the road at what buyers are looking for.

1. Uncompromising Quality and Craftsmanship

Uncompromising Quality and Craftsmanship High craft is what most distinguishes the best China makers. You can feel the attention to detail in every item, from delicate filigree prongs in diamond rings to satin finished metal work on cuff bracelets.

Brands such as Tiffany & Co and David Yurman are recognized for their clean lines and intricate craftsmanship. Whether it’s hand-setting stones or using laser welders, those things add that layer of polish. That attention to detail attracts customers looking for a high-quality, unique product.

2. Commitment to Ethical Sourcing

Consumers don’t just want ethically sourced products—they expect them. China manufacturer fulfill this by choosing conflict-free gems and recycled gold.

Certifications such as Responsible Jewellery Council (RJC) or Fairmined Gold demonstrate genuine commitment. Each of these moves foster trust and alignment with the values that 3 out of 4 US shoppers now consider important.

3. Embracing Advanced Production Tech

Whatever the technology, producing work more quickly and clearly is key. With CAD software, they can create precise models and with 3D printing technology, makers can experiment with different shapes and forms with minimal waste.

HonHo Jewelry Manufacturer in China uses these technologies to produce waterproof, non-tarnish and gold-filled jewelry.

4. Blending Tradition with Innovation

The combination of hand skills and machines creates striking designs. Makers such as Alex and Ani take advantage of traditional wire-bending techniques combined with new plating technologies.

This mix continues to make the art innovative yet historically grounded.

5. Robust Quality Control Systems

The best shops have quality control built into each stage of production. They inspect stone under microscopes and perform stress tests on chains.

Identifying issues at an early stage leads to less returns and more satisfied customers.

6. Offering Unique Customization Options

Creating dreams Custom work looms large in the US. Makers allow buyers to choose stones, shapes, or even get names engraved.

Companies that have robust online shops can easily display and allow orders for these one-offs. This makes sure that buyers continually return.

Ethics and Sustainability Matter

Ethics and sustainability are now the cornerstone of jewelry manufacturing. Buyers increasingly demand to understand where their goods are produced, how they’re produced, and by whom. This sudden turnaround has forced all types and sizes of companies to seriously reconsider their supply chains and day-to-day operations.

Today, more and more buyers require evidence that products are ethically sourced. They are particularly committed to conflict-free diamonds and metals from certified mines that ensure the safety of workers and the preservation of the land.

Several companies are spearheading this transformation. Consumers trust brands, such as Brilliant Earth and Tiffany & Co., who are transparent about sourcing policies and supply chain. They utilize recycled gold and silver to reduce carbon emissions by more than 97%.

One recent example featured reductions of up to 58,000 metric tons per year! Waste management and sustainable packaging are becoming table stakes for companies. These kinds of homes convey concern for our planet as well as the homebuyer’s ideals!

Why Responsible Practices Count

Trust is everything. Responsible, quality work is the best way to earn trust and ensure repeat business. In a world where consumers have endless options, brands that prioritize people and the planet cut through the clutter.

In fact, ethical rules can help distinguish a company from the competition, earning the trust of dedicated consumers who are eager for their dollars to go further. In the long run, it’s these deep investments that reap handsome rewards in consistent sales and lasting worker connections.

They equally mitigate dangers related to negative media attention or litigation.

Understanding Certifications Like RJC

Understanding Certifications Like RJC Certifications like the Responsible Jewelry Council (RJC) create baseline ground rules for the industry. They help ensure that practices, and the materials that result from them, are aligned with international best practices for ethics and sustainability.

When companies succeed in obtaining these badges, it enhances their credibility and attractiveness tremendously. The process verifies the ways that firms are sourcing, tracking and managing their materials, providing buyers with confidence.

Reducing Environmental Footprints

Jewelry makers now use recycled metals, cut down on waste, and pick safe, less toxic methods. Sourcing from artisanal miners helps local jobs—45 million people rely on it.

Eco-friendly packaging, like biodegradable boxes, is on the rise. These steps shrink harm and help build a cleaner future.

Services Beyond Basic Production

Jewelry manufacturing companies today are about so much more than just the art of shaping metal and setting stones. Their service menu now runs the gamut from bespoke design to advanced production technology assistance. That move is perfectly in step with a market looking for the best of both worlds—big and small, scale and personal.

Flexible service allows manufacturers to support brands, designers, and retailers of all shapes and sizes—and all creative visions—scale. Value-added services—such as production trend reports or inventory planning—build client confidence and incentivize long-term loyalty.

Custom Design and Prototyping

Custom design often begins with hand sketches or CAD models. Clients collaborate with internal design teams to choose metals or stones, routinely using online collaboration tools to make rapid adjustments. Prototyping allows clients to visualize and make adjustments to individual pieces before committing to full production.

Some shops, for instance, have assisted indie brands in developing engagement ring lines, which incorporate lab-grown diamonds and distinctive settings. This collaborative back-and-forth process helps catch mistakes and strengthens the piece so it aligns with the client’s goals.

Full-Scale Manufacturing Capabilities

Even for the biggest orders, a good system goes a long way. Full-scale production facilities employ precision technologies—such as German casting or laser soldering—to ensure each unit meets quality standards over thousands of units. These facilities are able to control short schedules and budgets through careful project planning.

As an example, one China Manufacturer has in-house integrated workshops for mold making, stone setting and plating. This reduces their lead times and allows them to service both small and national accounts.

Partnering with Designers and Brands

Partnering with designers and/or brands adds a new dimension. Working with designers or brands introduces new thinking. Certain manufacturers even support independent jewelry lines in the development of their seasonal collections.

These collaborations leverage mutual marketing intel and broad gemstone offerings to access larger consumer bases. The outcome could be a recycled metals ring line or a solar-powered pendant collection.

Wholesale Manufacturing Solutions

With these wholesale agreements, retailers receive a consistent supply and stock maintenance support. Collaborating with manufacturers goes a long way in tracking inventory and streamlining logistics, allowing retailers to keep their bestsellers in stock.

Some even include carbon accounting and ESG reporting baked into their service, which sweetens the deal for sustainability-conscious print shops.

Importance of Quality Commitment

Quality commitment in jewelry manufacturing not only influences immediate trust but also affects long-term prosperity. Businesses in this space are committed to high quality from the bottom up, beginning with their raw materials. Their production team operates from a zero-waste philosophy, utilizing recycled metals and sustainably-sourced gems and diamonds to create responsible jewelry. This approach ensures that the supply chain remains clean and fair, a concept that is increasingly important in our global market. Almost all China jewelry manufacturers are currently using recycled metals, sourcing from mines that adhere to Fair Trade standards. These steps significantly reduce social and environmental harm while cultivating positive brand equity.

How a company inspects its work is equally important in the realm of custom jewelry manufacturing. Most businesses conduct validations at every stage, rather than only at the final destination. This includes a close inspection of the cut, polish, and setting of each stone, which is essential for testing the tensile strength of clasps and chains. Many jewelers even employ advanced technology, such as microscopes or lasers, to detect defects that are invisible to the naked eye. This meticulous process prevents subpar or counterfeit items from reaching consumers. For customized or luxury goods, some factories provide a detailed report or certificate outlining each component and process involved.

A firm quality position plays an important role when facing returns or repairs in the jewelry business. Quick, transparent methods to resolve issues or facilitate returns give the impression that the brand is confident in its product. Buyers who feel well taken care of are more likely to return or refer friends. In a city like LA, where trends and tastes change rapidly, this unwavering commitment to quality is what enables shops to thrive in a competitive market.

Key Players in Supply Chain

Jewelry manufacturing in China, from mine to market, relies on a chain of individuals and companies, each playing a distinct and vital role. It begins with the suppliers that provide the raw gold, silver, platinum, or gems. All leading manufacturers choose responsible jewelry suppliers, ensuring that the metals and stones they use are authentic and traceable. These places have developed massive networks and rigorous design standards to support the jewelry business.

Following the suppliers, the designers and artisans take those inspirations and ideas and turn them into tangible works. Some of these companies may operate with in-house design teams, while others collaborate with local freelance artists. Hiring local creative talent helps them stay in touch with the latest trends, especially in rapidly evolving runway cities like LA or New York. This edge is invaluable! These teams have access to all sorts of machines, including CAD design technology and laser cutters, enabling them to create custom jewelry products efficiently.

Production companies—usually located in metropolitan areas with vibrant jewelry industries—assemble the components. They handle casting, setting, polishing, and quality checks under one roof. Most everything produced by China firms is based on a small run, allowing them to maintain a higher standard of quality fine jewelry. They rely heavily on local workshops, but larger ones use overseas partners for specific processes, such as stone setting or plating, to enhance their custom jewelry manufacturing.

At the end of the supply chain, distributors and retailers take the completed pieces to market. Some responsible jewelry brands sell directly to consumers online, while others supply large retailers like Walmart and Target, or even mom-and-pop shops. Companies based out of Los Angeles or New York heavily rely on trade shows and local wholesale jewelry markets to quickly get in front of buyers. Every single player in the supply chain is critical to maintaining quality and controlling costs.

Navigating Industry Trends & Challenges

Jewelry manufacturing today faces accelerated transitions fueled by global market expansion and technological innovation, particularly within the realm of responsible jewelry. As the world jewelry market is set to reach $482 billion by 2030, businesses must navigate tricky decisions to remain competitive in the custom jewelry manufacturing landscape. This growth brings challenges, from environmental regulations to changing consumer preferences, prompting brands to adapt their strategies effectively.

Adapting to New Technologies

Technology is changing the jewelry creation process both in the front and back of house. With artificial intelligence, design is accelerated and trends are identified at a greater velocity than we’ve had access to in the past.

3D printing enables creators to produce bespoke components while minimizing waste and reducing the potential for mistakes. Certain brands even incorporate repurposed coffee grounds and used Nespresso pods to create truly unique products.

HonHo Jewelry Manufacturer, on the other hand, refines stainless steel, brass, and 925 silver to make jewelry, providing waterproof and non-tarnish jewelry. These improvements allow us to increase both speed and quality while maintaining (and even reducing) costs.

Meeting Shifting Consumer Demands

Buyers today demand more than aesthetics. They demand integrity. Unsustainable practices about 71% seek brands that practice environmentally safe methods and pay more for it.

Makers save time and money by tapping into an industry trend to use recycled metals and maintain supply chain transparency. Many other brands leverage digital assets and NFTs as bridge-building tools to get connected with younger buyers.

Some others are modifying traditional formats for a more senior-friendly experience. Surveys, social media, and direct feedback from retailers and customers allow brands to understand what consumers are looking for before they even launch the new lines.

Staying Competitive in the Market

In order to lead, brands can never stop innovating and improving. Tightened production techniques and zero-tolerance adherence to guidelines reduced chances of expensive recalls.

With economic swings and inflation driving buyers to look for long-term value, brands need to find that price vs quality harmony. It’s innovators—those who embrace their future, whether that’s the use of sustainable materials, digital technologies, or other advancements—who experience the greatest growth.

Conclusion

Jewelry manufacturing in the US is full of talent, passion and ingenuity. Inspiring makers demonstrate true integrity, from sourcing fair trade metals to incorporating innovative technology alongside traditional craftsmanship.

Shoppers are no longer satisfied with just stylish options—they’re demanding fair wages for factory workers and true green alternatives. In response, US firms respond with demonstrable experience and consistent deliverables. Custom jobs, repairs and small-batch runs get people the goods they desire with a quick turnaround.

Big names and small shops both ride trends but stick to what works: trust, good hands, and open talk. Looking to figure out who would best fit into your team? Read reviews, have questions, and expect honest answers from a craftsman. Discover what these shops are doing—there’s so much more than just bling.

Frequently Asked Questions

What do jewelry manufacturing companies do?

Jewelry manufacturing companies are responsible for creating custom jewelry products by transforming jewelry designs into completed pieces. They oversee the entire process from sourcing quality materials to finishing each item, ensuring consistency and quality for their retailers and responsible jewelry brands.

How do China jewelry manufacturers source their materials?

China jewelry manufacturers prioritize sourcing conflict-free stones and recycled metals, aligning with the Responsible Jewelry Council to advocate for responsible mining and fair labor practices.

What makes a top China jewelry manufacturer stand out?

Top China manufacturers of responsible jewelry offer expert craftsmanship and custom jewelry manufacturing services, setting the bar high for quality and on-time delivery in the jewelry business.

Why is sustainability important in jewelry manufacturing?

Sustainability protects the planet and fosters fair labor practices, leading consumers to seek responsible jewelry brands that prioritize recycled metals and conflict-free stones in their custom jewelry manufacturing processes.

What services do jewelry manufacturers offer beyond basic production?

Most responsible jewelry makers will provide everything from design consultations and CAD modeling to rapid prototyping and custom jewelry manufacturing services. Many also offer repair, resizing, remounting, and private label services for other jewelry brands.

What are the biggest challenges in China jewelry industry?

Key challenges for responsible jewelry makers include price fluctuations for gold and gems, adapting to new technologies, and supply chain disruptions.

How do I choose the right jewelry manufacturer in China?

Choose a responsible jewelry manufacturer that values their reputation, is open and forthright with information, prioritizes ethical sourcing and practices, and has a diverse portfolio of custom jewelry products that reflect your aesthetic.

Related Posts

Understanding Wholesale Jewelry Pricing and How It Works

Understanding Wholesale Jewelry Pricing and How It Works When people see a ring that costs $6 wholesale and retails for $59, they often

The Art of Shine in Jewelry Polishing and Plating Techniques

Discover how polishing and plating transform modern jewelry with expert techniques for lasting shine and elegant finishes.

Τι Νοιάζει Πραγματικά τους Αγοραστές Ανοξείδωτου Κοσμήματος Εκτός από την Τιμή

Τι πραγματικά νοιάζει τους αγοραστές ατσάλινων κοσμημάτων πέρα από την τιμή ανθεκτικότητα υποαλλεργικά υλικά και μοντέρνο στυλ.