Understanding The Thickness of Gold Plating: Guide 101 to Durability & Quality

Key Takeaways

- Gold plating is a method in which a very thin layer of gold is layered onto the base metal. This process makes the product more beautiful, durable, and valuable while still being affordable compared to solid gold.

- The thickness of gold plating is extremely important regarding wear resistance, corrosion protection and life expectancy. The heavier the plating, the more protection it provides.

- Recommended thickness differs depending on item type. Jewelry and watches typically need at least 3 mils of plating to stand up to everyday wear. In contrast, decorative or electronic applications might be satisfied with a much thinner deposit.

- Precise measurement and ensuring uniformity in thickness are essential to quality control, usually done through measurement technologies such as X-ray fluorescence (XRF).

- With proper care, avoiding harsh chemicals and rough treatment, the finish will be protected and gold-plated treasures can last for generations.

- Understanding the differences between gold plating, gold filled, vermeil, and PVD coatings helps consumers choose the most suitable option for their needs and budget.

Unfortunately, the thickness of gold plating provides a measure of how much gold has been applied to an object’s surface. In the United States, we usually specify this thickness as a microinch or micron. For comparison, most jewelry and electronics gold plating is between 7 microinches and 200 microinches thick.

Thicker gold layers are more expensive but improve durability and appearance. Thin penetration of gold plating doesn’t last and is more likely to wear off quickly. In the U.S., consumer products marked “gold plated” or “heavy gold electroplate” are required to meet certain thickness guidelines.

These voluntary standards, established by the Federal Trade Commission, promote high quality and transparency. Understanding the appropriate gold plating thicknesses allows consumers to choose jewelry, watches, or electronics that meet their lifestyle and budgetary requirements. The following paragraphs explain the most prevalent standards and how they affect buyers.

What Exactly is Gold Plating?

In electronics, gold plating deposits a thin layer of gold over another metal, usually copper or silver. This can be done chemically or electrochemically. This enhances the appearance and value of products without the expense of pure gold.

Gold plating is prevalent in jewelry, electronics, watches and even home décor. Although solid gold is stronger, it is infinitely more expensive. If you want something that looks like gold plating, but the layer of gold doesn’t wear off over time (as it inevitably will when it’s thin, gold-plated), there are alternatives available.

The Basic Plating Process Explained

The plating process begins with surface preparation, or removing all contaminants from the surface of the workpiece. Even a fingerprint or dust particle can ruin the final appearance.

Electroplating is by far the most common process. It employs a low-voltage electric current to facilitate the adhesion of gold to the base metal. The object is immersed in a solution containing gold ions.

The direct current moves the gold to the object’s surface. There are multiple kinds of solutions. Your decision depends on the application of the end product, whether that’s jewelry, electronics, or something else entirely.

Why We Use Gold Plating

Gold plating provides an immediate eye-catching bright color and lustrous shine that attracts attention. That’s because it’s more cost effective to use gold plating instead of solid gold, saving on costs.

Besides providing a beautiful finish, gold also acts as a protection for the base metal against abrasion and corrosion. This durability factor is what makes plated goods ideal for applications such as wedding bands, necklaces, and even electronic circuit boards.

Gold plating is used for many reasons. It’s found in everything from HonHo’s custom, waterproof, gold-filled jewelry in China to the components in our technology.

Base Metals Commonly Used

Copper and silver are commonly used metals for gold plating. The choice of base metal affects the appearance and durability of the plated item.

Not all metals work the same with gold plating, so picking the right one is key for durability and shine.

Why Gold Plating Thickness Matters Most

The thickness of gold plating is more than a technical footnote. It truly matters when it comes to the appearance, tactile experience and longevity of your jewelry and other products. Knowing why thickness matters helps both buyers and makers. Understanding this results in wiser decisions, more durable products, and a better understanding of value.

Here’s our breakdown of each aspect of gold plating thickness. It illustrates how it affects day-to-day usability, aesthetics, budget and beyond.

1. Durability: How Thickness Fights Wear

Gold plating thickness is crucial in determining how well jewelry items endure the rigors of everyday life. A thicker gold coating provides enhanced protection from scratches, tarnishing, and the inevitable little bumps associated with daily wear. Gold-plated watches featuring a 2.5-micron thickness fall under the classification of “heavy” plating according to governmental criteria, making them more resilient against fading and pitting compared to products with thinner layers. Jewelry with a gold plating thickness of 0.5 microns, on the other hand, will start to lose its finish within months, particularly with daily use!

Gold-filled products boast a significantly greater gold layer, which can last 20 years or more when well maintained. For wearables, durability is essential, as these pieces face high everyday abuse. Therefore, making the right choice regarding gold plating options is more than just a cosmetic decision; it plays a vital role in preventing corrosion and electrolysis, major contributors to wear and tear.

Ultimately, the gold electroplating process should be carefully considered to ensure the longevity of your jewelry. Choosing the right plating thickness is essential for achieving a protective gold coating that will stand the test of time, especially for delicate jewelry pieces that require an attractive finish.

2. Appearance: Achieving That Lasting Shine

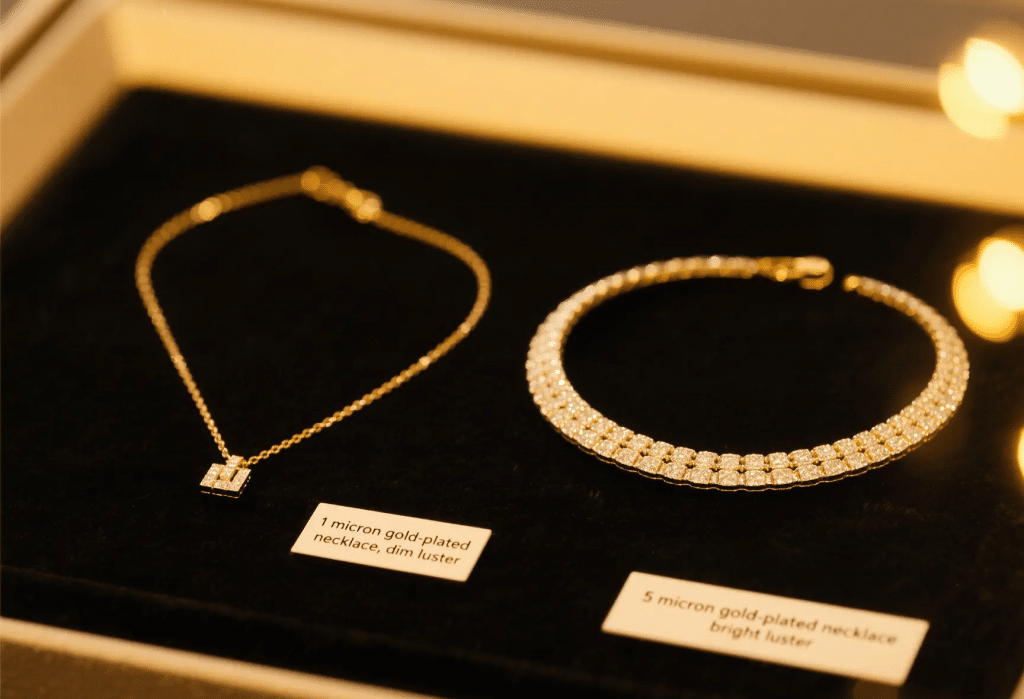

The thickness of the gold plating process significantly determines the appearance of gold plated products. A thicker gold coating results in a more vibrant, brilliant shine, ensuring that the classic gold hue remains consistent throughout. In contrast, thin gold coatings can start to look dull or patchy as the base metal shows through, while thicker plating options maintain that bright, smooth finish.

Nothing beats the eye side-by-side visual difference. For instance, a necklace with a 1-micron gold plating would look gorgeous on day one, but its sheen doesn’t last as long as necklaces made with 2.5 or even 5 microns. To preserve that appearance, regular cleaning and delicate handling are essential.

Ultimately, the thickness of the plating layer is what really makes the difference in how long that gorgeous look lasts, highlighting the importance of selecting the right gold plating service.

3. Value Perception: Thickness and Quality

Consumers typically associate gold plating thickness with quality and value. The added thickness provides a very obvious feel of quality, along with the aesthetic appearance of looking more “real,” which provides that luxury perception. The jewelry industry knows this strategy all too well.

In fact, brands often advertise the thickness of their gold plating, touting the microns as a measure of quality. Clearly stating the gold plating thickness in product listings allows customers to make more informed decisions and creates a sense of transparency and trustworthiness.

HonHo Jewelry Manufacturer in China makes the difference. On their website, they have no qualms about specifying the thickness of their gold vermeil and gold-filled items. This level of transparency and integrity allows for informed purchasing decisions and an understanding of the value of the product.

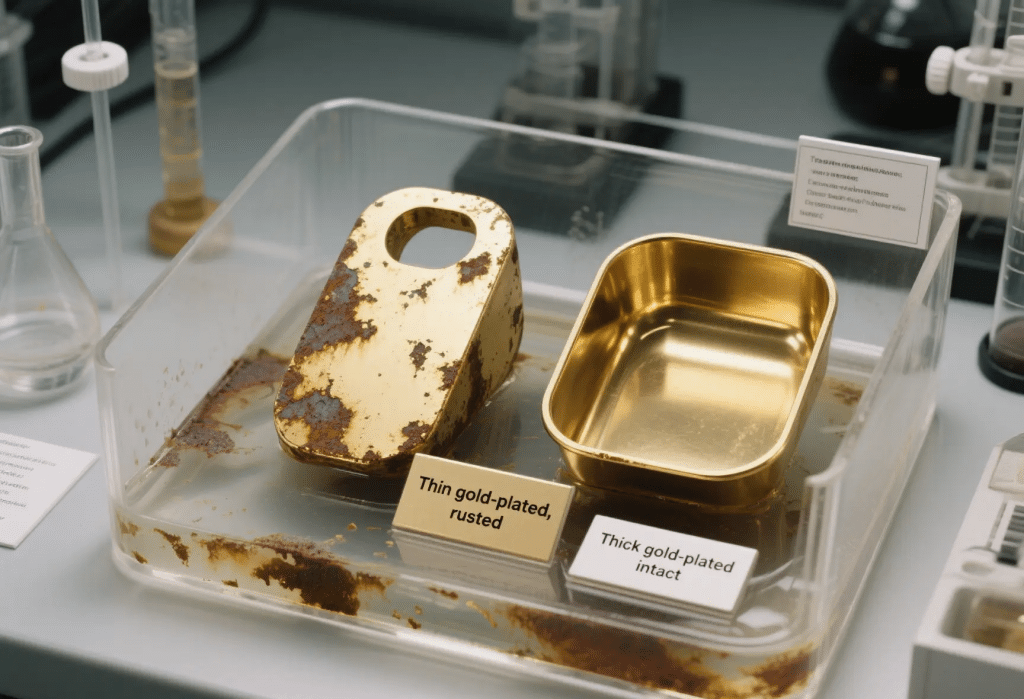

4. Corrosion Resistance: Protecting the Base

Gold does not rust, though many of the underlying metals will rust or corrode. The greater the thickness of the gold layer, the better it will protect the base by warding off water, sweat, and air. When plating is inadequate, these elements have the opportunity to penetrate and corrode the base, resulting in tarnish or worse.

For items worn often or in damp places—like bracelets, rings, or watches—a thicker layer is key to keeping the base metal safe. In the long run, that translates to less concern about green tarnish, peeling, or plastic-like odor over time.

The reward is an end product that can really withstand the elements and continue to look good over time.

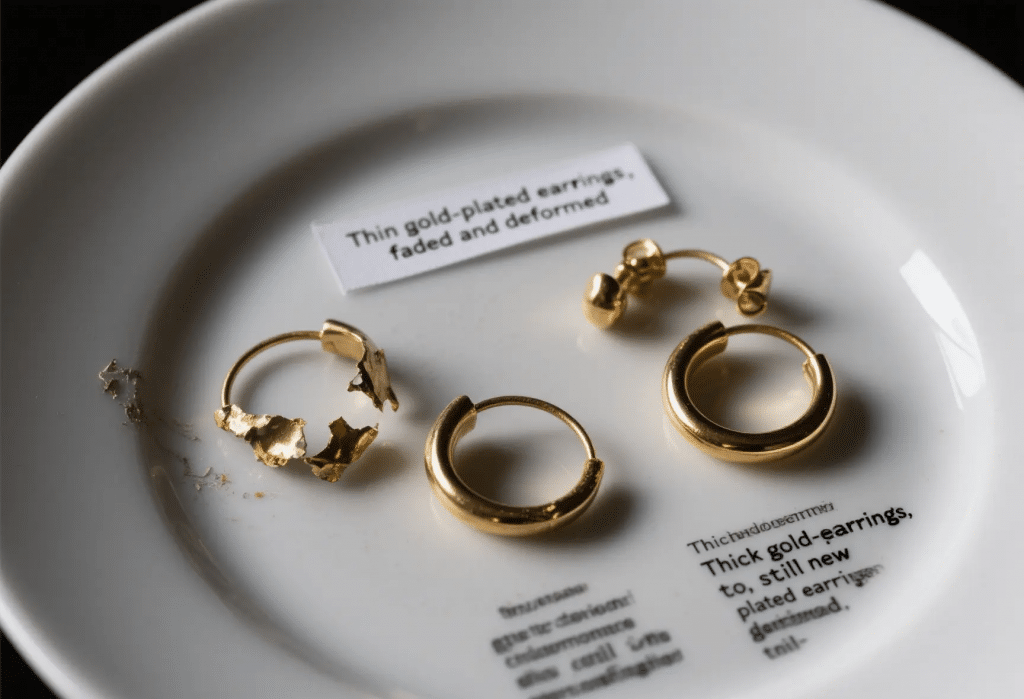

5. Longevity: Making Your Pieces Last

Related to how long a piece lasts, longevity—making your pieces last—is crucial. How long will your gold-plated items last? Thin layers rub off quickly, but thicker ones can endure decades of wear. If you only wear your earrings once a month, then a thinner coating is just fine.

When dealing with a daily-wear ring, you’d want a heavy-duty protection of 2.5 microns or greater. Proper care—like keeping jewelry dry and clean—can help, but thickness is always the main factor in how long the good looks stay.

6. Skin Sensitivity Considerations

For these individuals, thickness matters in a different sense. When thin gold layers wear off exposing the base metal underneath, skin rashes or irritation from itch can occur. The thicker the plating, the longer it protects as it keeps the base metal sealed inside.

Selecting hypoallergenic bases such as stainless steel or silver, like HonHo uses, provides an additional level of protection. For those with a history of skin reactions, seek professional advice before purchasing any gold plating. To be safe, think of performing a patch test.

How Gold Plate Thickness is Measured

Gold plate thickness matters for both look and lifespan. A thin layer can wear off fast, while a thicker coat lasts longer. Getting the thickness right is key for quality, whether it’s for jewelry, electronics, or other goods.

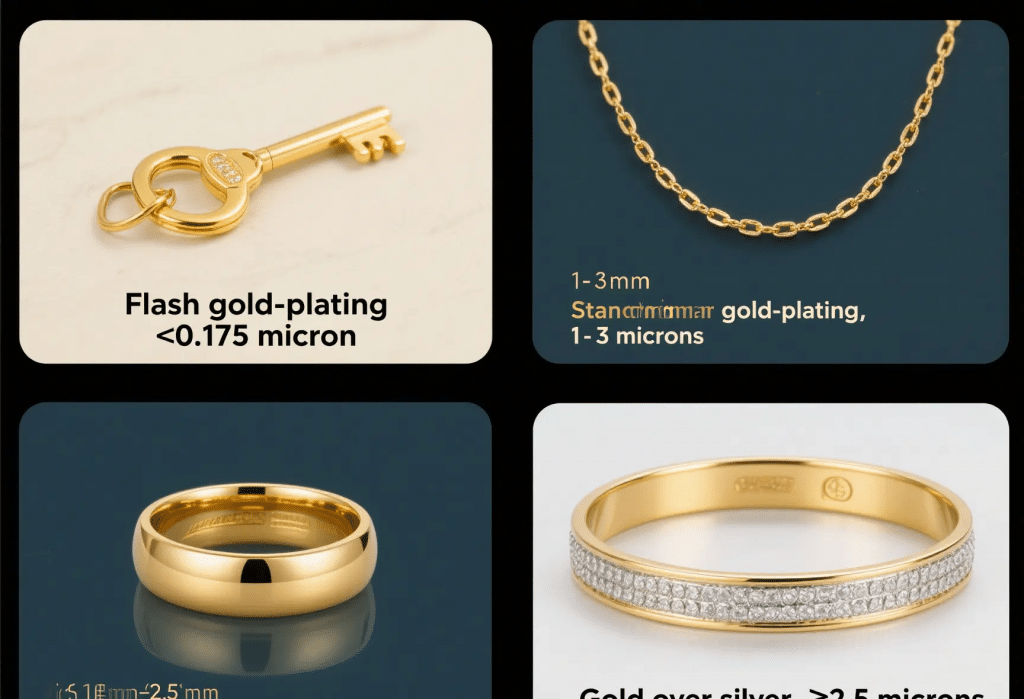

In the U.S., experts use microns (µm), micro-inches (µin), and sometimes mils. One micron equals 40 micro-inches. One mil is 1,000 micro-inches. For context, 1 micron is already considered decent for daily wear. Jewelry often needs 2–5 microns for solid durability, but flash plating is thinner—under 0.175 microns.

Understanding Microns (µm)

A micron, or one-millionth of a meter, is the main way to measure gold plating. This helps give a true sense of how thick the layer is. The bigger the number, the sturdier the gold coat.

For example, a layer under 0.2 microns is called “flash plating” and is mostly for looks. A thicker plate, like 10 microns, feels solid and lasts. Knowing these numbers helps buyers make smart picks and compare products.

For each square inch, one micron of 24K gold weighs close to 12.45 mg.

Common Measurement Techniques (XRF)

Common Measurement Techniques X-ray fluorescence (XRF) stands out as the clear favorite for measuring gold plate thickness. It’s fast, it’s non-destructive and it’s portable.

XRF is about as simple as it gets—shine a beam of x-ray energy, read how the gold reacts, and spit out the thickness in microns or micro-inches. There are other methods such as micrometers or weight checks, but XRF excels in speed and accuracy.

In quality control applications, precise readings are of utmost importance.

Ensuring Thickness Consistency

Consistent, even plating creates durable products. To ensure consistency from piece to piece, most plating shops employ regulated plating baths and consistent, monitored electric currents.

Inconsistent thickness can lead to areas of weakness or lackluster appearance. Our quality control ensures that any potential problem is detected early, so that every plate we produce meets or exceeds our high standards.

Decoding Common Plating Thickness Levels

Gold plating is manufactured in a variety of thickness levels, with each gauge intended for a specific application. Understanding these categories of thickness can better equip buyers to align the desired quality and associated cost with actual requirement.

Now you’re faced with a huge decision, everything from the most delicate flash plating to thick, durable gold vermeil. Each choice has an effect on the piece’s durability, appearance, and cost. Selecting the appropriate plating thickness is extremely important in the jewelry and electronics industries. It can mean the difference between a piece lasting for decades versus rapidly wearing out.

Flash Plating: A Quick Dip

With flash plating, the thickness of the gold plating is very minimal, usually under 0.175 micron. Essentially, it’s for decoration and appearance rather than function and durability. Consumers experience this in the form of customer jewelry or novelty items – things you’re not expecting to hold up for a long time.

Though it creates a great effect on low-cost products, the effect wears off rapidly and doesn’t stand up to human perspiration or water. Flash plating does not suffice for parts that experience heavy wear or for connectors that require corrosion resistance.

Standard Micron Plating: The Norm

Standard micron plating is typically 1 to 3 microns. So does the majority of typical gold jewelry you see. It’s the sweet spot—thick enough to withstand a fair amount of scratches and sweat, but not so thick that it breaks the bank.

For the average person using plated products, this thickness is enough for everyday use. It’s not just in plating too—this is standard in electronic applications, with 0.1-0.5 micron layers being very common for connectors in non-harsh, non-handled environments.

Heavy Gold Plating: Built to Last

Heavy gold plating starts at around a thickness of 2.5 microns and increases from there. It’s meant for rings, watches, or connectors that get pounded on. The added thickness of gold plating prevents corrosion and can withstand true industrial wear and tear.

For high-end products, this level brings increased durability and luster. For maximum protection, certain connectors will require as high as 100uin (2.5um) for optimal performance.

Gold Vermeil: A Special Case

Gold vermeil is a specific type of plating, applicable only to sterling silver bases. By definition, the gold layer must be a minimum of 2.5 microns. This brings it up to par or better than most typical plated items.

Gold vermeil has a luxurious appearance, is more durable and resistant to tarnishing. At HonHo Jewelry Manufacturer located in China, we specialize in creating beautiful gold vermeil pieces using either stainless steel, brass, or 925 silver.

We design custom waterproof, gold-filled pieces that tarnish with beauty.

Recommended Thickness for Different Items

There is no one-size-fits-all gold plating thickness. The exact thickness varies greatly based on the item’s expected functional use, aesthetic intent and longevity. In the U.S., typical thickness for gold-plated items begins at around 0.05 microns.

Most brands use three levels: “flash” plating at 3 micro-inches (µ”), standard at 10 µ”, and heavy at 30 µ” or more. Vermeil pieces require a minimum of 2.5 microns, and gold-filled items must have a minimum of 5% of the total weight in gold. These things are important because a micron is about 40 times larger than a micro-inch.

For reference, one mil of 24K gold plate weighs 0.316 grams per square inch.

Jewelry: Rings, Necklaces, Earrings

Jewelry—rings, necklaces and earrings—require thicker plating as they are subjected to the rigors of everyday wear. Flash plating is very thin and should only be used for earrings or other jewelry not worn on a daily basis.

For rings or bracelets, minimum 10 µ” prevents fading as these experience more rubbing and bumping. Design matters too—heavier plating may soften fine details, whereas thinner platings allow for clean, crisp lines. Vermeil, with its 2.5-micron minimum, provides one of the best combinations of strength and appearance.

Watches: Cases and Bands

Watch cases and bands are subject to a lot more wear and tear, requiring thicker gold—usually 10 µ” or even 30 µ”. This ensures that the watch remains in immaculate condition and peak performance.

Excess gold, anything more than 100 micro-inches, actually stresses the layer, creating cracks. Excessively thick plating can further add heft to a delicate watch, so aesthetics and comfort need to find a compromise.

Eyewear Frames: Style and Substance

Generally, gold on eyeglass frames features a thin gold coating—flash or standard plating—because using thicker layers would make the frames heavy. Comfort is crucial for frames worn all day, and while thicker gold plating can help prevent scratching, most frames typically adhere to the common thickness of 3 to 10 µ”.

Decorative Home Accents

For home accents, such as lamp bases or mirror edges, using thicker gold can enhance luster and durability. It is recommended that items which receive high degrees of handling have a thickness of 10 µ” or greater.

Going too thick will soften crisp edges, which is why most designers play it safe with an average thickness.

Electronic Connectors Performance Impact

Connectors require only the minimum gold thickness necessary to ensure a reliable contact—generally 10 µ” in critical wear areas. Too thick, and connection performance is compromised.

Too thin, and risk or performance loss increases. Finding the optimal thickness is crucial for signal integrity and hardware dependability.

Factors Influencing Plating Lifespan

The longevity of your gold plating significantly depends on various factors, including the underlying metals, which play a crucial role in the quality gold plating. Additionally, how the piece is worn, its exposure to elements, and the artistry involved in the gold plating process are essential. Each of these elements contributes to the durability of the gold layer, ensuring it maintains an attractive finish over time.

The Base Metal’s Role

The base metal’s role The metal underneath the gold, known as the base metal, plays a significant factor. Stainless steel is much better than brass or copper. If the base metal is pure and well prepared, the gold adheres better and will have a longer lifespan.

HonHo Jewelry Manufacturer in China provides high-quality custom durable gold plated jewelry from their attention to detail, high-quality materials such as stainless steel, brass, and 925 silver. When the base metal is incompatible with gold plating, the layer may peel or tarnish quickly.

How You Wear and Use It

How You Wear and Use It Makes a Difference For example, rings and bracelets tend to get hit harder than necklaces. If you’re someone who washes their hands often or wears jewelry while cleaning, the gold overlay will rub off faster.

Choosing heavier plating, at least 2-3 microns, goes a long way if you’re tough on your jewels.

Environmental Exposure Effects

Water and sweat, with exposure to air as well, can all destroy gold plating over time. Areas with high humidity or where chemicals are used frequently accelerate the process.

Common sense dictates that gold-plated things should be kept away from moisture and corrosive materials.

Quality of the Plating Job

Plating Quality A thicker gold layer—2.5 microns or greater—will withstand years of use with proper care and maintenance. How the gold is applied The specific plating method, such as electroplating versus other methods, plays a significant role.

How clean the base metal is a significant factor as well. An unprofessional job will wear away quickly.

Risks of Incorrect Thickness

If the gold is plated too thin, it will wear away within months. Too thin, and it could be overpowering or even ugly.

Avoid going below or above recommended thickness to maintain design integrity and aesthetics.

Caring for Your Gold Plated Treasures

Gold-plated treasures bring glam and glimmer to everyday jewelry, but that glow is only possible through proper care and attention. The thickness of the gold layer is a key factor in how long that glimmer will last. A thicker coat, around 1 micron or 40 micro-inch, can handle years of use if cared for properly.

Compare this to a very thin deposit of only 5 micro-inches which can discolor or wear away within a few days. That’s why keeping up with cleaning and smart storage is key for anyone who wants their gold-plated pieces to look good over time.

Gentle Cleaning Best Practices

Cleaning gold-plated items requires a light hand. When it comes to cleaning, use a soft cloth—preferably microfiber or cotton—and some mild dish soap mixed into warm water. Wipe gently to clean without scratching.

Do not use scrub pads or abrasive cleaning materials. They are very abrasive and can quickly scratch and thin the gold layer, particularly if the plating is on the thinner side. When tarnish does appear, use a soft cloth dipped in soapy water and rub lightly.

Allow the piece to air dry or gently pat it dry. This technique will preserve the appearance of the gold without endangering it with potential abrasives.

Smart Storage Solutions

Where you keep gold-plated jewelry matters. Store your jewelry in dry, cool places, avoiding direct sunlight or heat sources. Anti-tarnish pouches or cloths are an option to help slow the tarnishing process.

Make sure to store each item separately to prevent them from damaging one another. This is especially true for rings and bracelets, which are just generally touched more.

Activities and Chemicals to Avoid

There are several daily activities to avoid that are harmful to gold plating. Remove jewelry before going into swimming pools, exercising, or doing house cleaning. Sweat, chlorine and cleaning products can all dull or pit the surface of your item.

Even cosmetic products—such as perfume or lotion—can damage plating. Make sure to always wear jewelry last when dressing.

Plating vs. Other Gold Alternatives

When choosing quality gold jewelry or accessories, customers are frequently confronted with descriptors such as gold plated, gold filled, gold vermeil, or PVD. Each has its unique appearance, cost, and durability. Understanding the variations in gold plating specifications, thickness standards, and gold content will better inform buyers to make sound purchasing decisions.

Gold Plated vs. Gold Filled

Gold plated or electroplated refers to a process where a very thin layer of gold is electrochemically deposited on a base metal. In fact, the gold content in most plated pieces is well under 1% by weight. Gold plating does vary in the thickness of the gold layer from under 0.175 microns (flash plating) to 10 microns or greater (heavy plating).

Since it only requires a thin layer, this makes gold plating a more affordable option, though that layer will wear off with time. Gold filled employs very thick layers—20 to 100 times more gold than in plating. The majority of gold filled pieces are made using 14k or 18k gold, which is bonded to a base of brass or copper.

This provides much improved durability and an extended lifespan. Gold-filled jewelry is more expensive than gold-plated alternatives. It is the perfect option for everyday, practical wear and for those looking for a more long-lasting finish.

Gold Plated vs. Gold Vermeil

Gold vermeil is a US standard: a thick gold layer (at least 2.5 microns) on sterling silver. It is more durable than standard plating, which is a better option for those with sensitive skin. Compared to the other options, vermeil has a deeper shade of gold and a more substantial, solid weight.

So if you’re looking for that high-end look and feel without the price tag of solid gold, then gold vermeil is an excellent choice. At HonHo Jewelry, we handcraft a line of waterproof, non-tarnish, gold vermeil and gold-filled jewelry for all different applications.

Gold Plating vs. PVD Coatings

PVD coatings, or physical vapor deposition coatings, utilize vapor to chemically bond gold or color with the metal. This newfangled technique provides an ultra-thin yet hard coating, tougher than traditional plating. PVD stands up to scratches and fading, making it ideal for watches, rings and other outdoor wear.

It can be more expensive than standard plating, though it wears better and retains its appearance.

Conclusion

As you might expect, gold plating thickness is a huge factor. Thin layers only hold up under low wear or limited use. The thicker the layer, the more they endure the test of time and provide that everlasting glow. If you want to choose the right thickness, look for numbers that indicate the thickness in microinches or mils. The ideal thickness is different for heavy use items, such as everyday jewelry, compared to occasional use equipment.

It’s true that with the proper treatment, gold plating can last and maintain its appearance for many years. It is exceptional compared to other gold alternatives like gold fill or solid gold. With its striking beauty, you can have it all without spending a fortune. If you care about your next piece lasting, make sure to look at the thickness before purchase. Query, review the details, and choose what works for you.

Frequently Asked Questions

What is considered a good thickness for gold plating on jewelry?

The best gold plating thickness for jewelry items typically ranges from 0.5 to 2.5 microns (approximately 0.00002 to 0.0001 inches), with thicker plating options offering a more durable plating that lasts longer and is less susceptible to wear.

How is the thickness of gold plating measured?

Gold plating thickness, a crucial aspect of the gold plating process, is measured in microns (one micron is approximately 0.00004 inches) or micro-inches, ensuring quality gold coatings.

Does thicker gold plating mean better quality?

The bottom line is that thicker gold plating doesn’t necessarily indicate better quality gold. This is especially important for everyday jewelry items like rings and bangles.

What is the minimum thickness for gold plating in the United States?

In the United States, the minimum thickness for gold plating, particularly heavy gold electroplating, is generally considered to be 2.5 microns (0.0001 inches) and up.

How long does gold plating typically last?

How long does quality gold plating last on average? It depends on the gold plating thickness, the type of item, and how frequently you wear it or expose it to water and chemicals.

What’s the difference between gold plating and gold-filled?

Gold-filled jewelry features a significantly thicker layer of quality gold plating compared to gold-plated items, making it more durable and better able to withstand daily wear than standard gold plating services.

Can gold plating be reapplied if it fades?

Yes, quality gold plating can be reapplied if it fades, helping to restore the shiny finish of your jewelry items and making them look like new again.

share this recipe:

Still hungry? Here’s more

Best Steel Jewelry Manufacturers 2026: Expert Guide

Have you ever wondered what it takes to create the stunning steel jewelry you see

7 Best Titanium Jewelry Manufacturers in 2026: Expert Guide

In recent years, the demand for titanium jewelry has skyrocketed, and for good reason. This

The Ultimate Guide to Titanium Jewelry: 8 Surprising Facts You Need to Know

In the world of jewelry, trends come and go, but some materials stand the test

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.