How to Find a Jewelry Manufacturer: Best Guide丨May 2025

When looking for how to find a jewelry manufacturer, I always begin my search by looking at trade directories, reputable online resources, and trade shows.

From there you’ll know how to weed out the makers who best align with your aesthetic, pricing goals and production needs.

All said and done, reading reviews and getting in contact with them directly will do you a world of good in deciding who’s the best fit for your line. Knowing what to ask for in terms of materials, batch size and timelines helps to demystify the process.

In our guide below, I’ve broken down each step to help make your search a little easier and more efficient.

What is Jewelry Manufacturing?

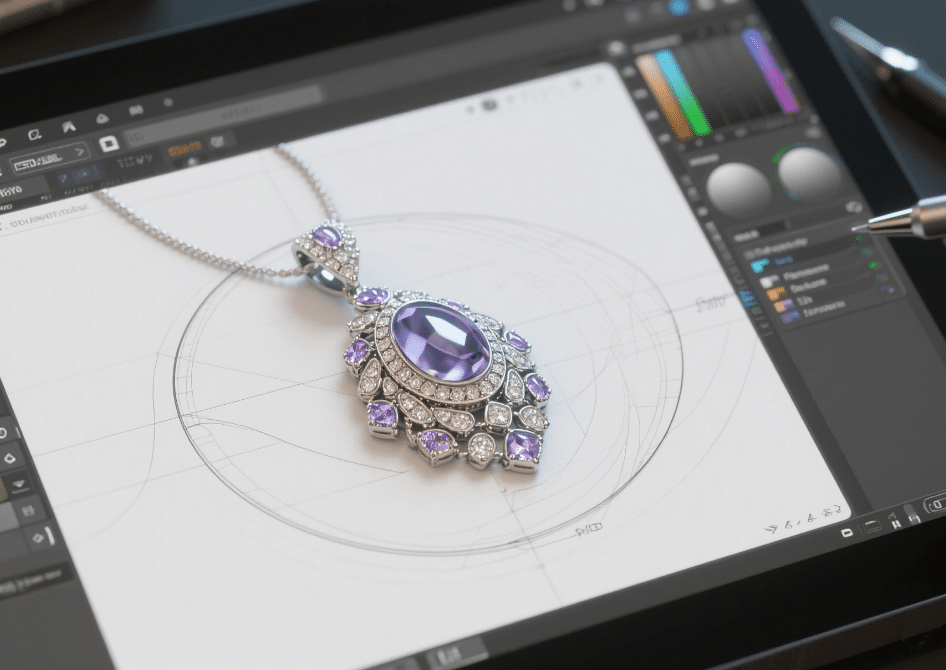

Jewelry manufacturing definition The act of creating jewelry from raw materials like gold, silver, platinum or gemstones. This manufacturing process uses the talents of skilled artisans and the latest technology to turn imaginative ideas into a wearable reality. Typically, this begins with a hand sketch or 3D digital rendering, which is essential for effective custom jewelry manufacturing.

First, you’ll see how many jewelry manufacturers use CAD (computer-aided design) to create exactly the right proportions. Working with CAD, you’re able to see the potential design from all angles and perspectives. You’re able to customize the size in general, the layout of the stones, and the tiniest aspects.

Consider a ring you want to design, for example. You can easily edit it and just move a few lines around on a computer screen, which demonstrates the latitude that experienced jewelry manufacturers allow.

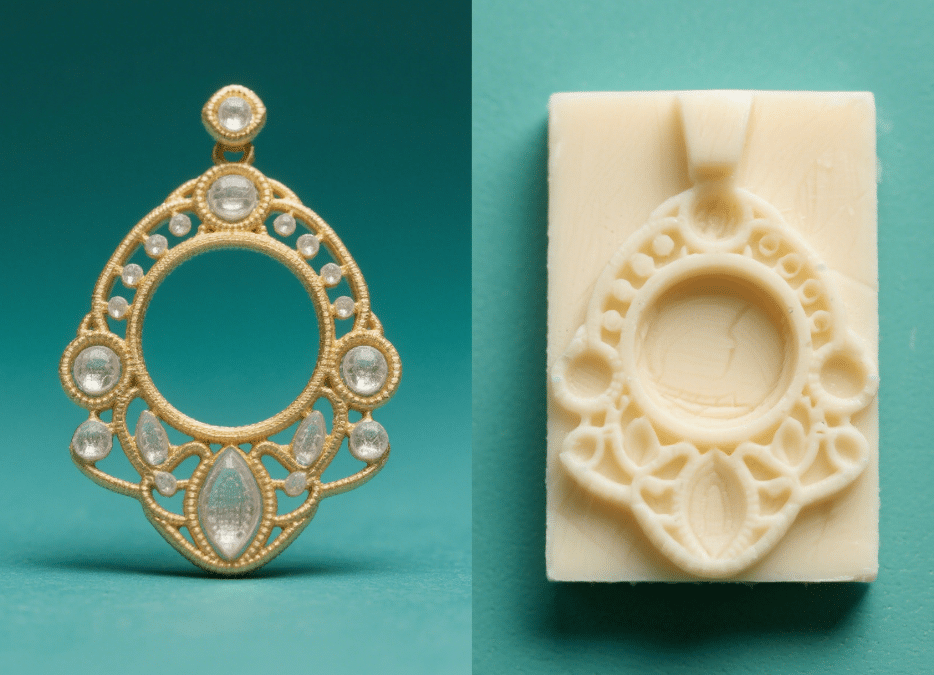

After finalizing the design, you move on to the next big phase called prototyping. This is where you create your first sample piece, which can be crucial for ensuring quality control checks. Some people still use wax molds, while others prefer 3D printing, which has become popular among custom jewelry manufacturers.

On the other hand, wax carving is still the greatest method of production for special, one-off pieces. From a production standpoint, a 3D printer would be considered quite fast and very repeatable. If you’re looking to create a large run of multiples of the same item, it’s absolutely the best option!

Now picture not just one, but a whole line of beautiful artisan silver pendants. Each one can be an exact copy of the it-of-the-moment pendant! This approach helps streamline the process and creates effective jewelry manufacturing production.

Once you receive the sample back, review it, and give approval, you can start your full production run. This is where you literally melt down and fuse together different precious metals. Next, you cast them into molds and form and finish them with a variety of hand and machine processes.

Stone setting, polishing and finishing then add the final touches that create the look and feel that special piece needs. Exceptional jewelry today is made as such, not just a little step above because of incredible technique supported by some very advanced technology.

You need to see master goldsmiths with calloused jewel worker’s hands that will just clamp that stone straight into position. You begin to realize you need hands that can polish metal to a mirror-like finish. This results in a product that’s as smooth as silk.

Laser welders and automatic casting machines help them create new pieces faster and with fewer mistakes. These special characteristics achieved with traditional hand tools are what allow artisans to add the little extra touches of meaning that matter.

They’re capable of weaving lacy embellishments in the metal and sculpting a gorgeous undulated finish. They can even invisibly hide a microscopic diamond, an example of their custom jewelry artistry.

Artists combine that intuitive craft with all the latest technological tools to create what’s next. They manufacture durable, aesthetic, impactful products that thrive in the public realm.

You’ll find this special blend in each of their businesses, from Order of the Wand to Hammer form. The right mix of craft and machines means better quality, faster work, and more ways to bring a jewelry line to life.

Define Your Jewelry Brand Needs

So, to find the right jewelry manufacturer for your business, start by pinpointing what you want your brand to convey. Then, have a concrete idea of what you plan to bring to your customers. This crucial step lays the groundwork for each of your decisions to come.

It informs how you present yourself aesthetically, and it helps you find your pricing. A clear brand plan helps you talk to suppliers, builders, and buyers in a way that feels true to your goals.

Understanding how to find a jewelry manufacturer is essential for ensuring that your ideas are brought to life effectively.

Identify who your brand is speaking to before you expand into other niches or materials. Think about what feelings or sentiments you want them to experience when they interact with your products.

Key factors to weigh when shaping your brand’s needs include:

- Target audience (age, lifestyle, buying habits)

- Market spot (luxury, mid-range, or budget-friendly)

- Brand story and values

- Design style (bold, simple, classic, or modern)

- Main goals (brand awareness, sales target, or social impact)

- Preferred sales platforms (online, in-store, pop-ups)

- Social media plan and presence

- Turnaround time and delivery needs

- Minimum order quantity (MOQ) and production needs

Every time you align your jewelry creations to the fundamental principles of your brand, you build trust. Even something as simple as promoting a collection that uses recycled gold lets shoppers know that you care about the health of our planet first.

When you establish objectives, you allow your pursuit of a manufacturer tangible form. A tangible goal, like introducing a new fine line or reaching a revenue target can serve to create that focus.

Pinpoint Your Niche and Style

Break down what your buyers love. Fine jewelry draws those who want rare gems or gold. Fashion pieces fit folks who like to change styles often. Artisanal lines call out to those who love hand-made work.

Tracking trends allows you to identify gaps, such as silver with eco-friendly features or a gender-neutral aesthetic.

USPs that set your brand apart include:

- Custom designs with CADs

- Unique stones or finishes

- Fast turnaround time

- Flexible MOQ for test runs

- Eco-friendly or fair-trade focus

Determine Material Requirements

Decide what materials you want your jewelry made from, whether it’s gold, silver, brass, etc. Choose your stones—be it diamonds, sapphires, or lab-grown. If sustainability is your main concern, choose upcycled or traceable items.

Test each type for durability and look. Supplier sources are key. Draw up a short list of suppliers for each. Identify a supplier for your gold, a supplier for your colored stones, etc.

Estimate Production Volume Needs

Decide how many pieces you want to have available to sell. Account for the previous year’s metrics, what you’ve already budgeted for ads, and big events on the horizon.

Things get even more complicated if jewelry sales suddenly spike during the holidays or wedding season.

What shapes production volume includes:

- Marketing pushes

- New collection launches

- Seasonal trends

- Events like pop-ups or trade shows

Set Your Budget Parameters

Note each cost—material, production, shipping and handling, overhead, etc. Set a realistic budget that does not compromise on the quality of jewelry, yet gives your brand enough to create a wow factor.

| Manufacturer | Materials Cost | Labor | Overhead | Total Cost |

|---|---|---|---|---|

| Brand A | $20,000 | $8,000 | $2,000 | $30,000 |

| Brand B | $16,000 | $10,000 | $2,500 | $28,500 |

| Brand C | $21,500 | $7,500 | $2,200 | $31,200 |

Consider Ethical Sourcing Goals

Decide what “ethical” means to you and your jewelry business. Read more about Fair Trade or RJC certification stamps. Ask designers how they treat their laborers, where they get their stones from, what they do to protect the environment, etc.

Questions for makers include:

- Where do you get your metals and gems?

- What are your labor rules?

- Do you have Fair Trade or RJC marks?

- How do you check for quality?

- Can you work with special or green goods?

Where to Find Potential Manufacturers

If you’re wondering how to find the right jewelry manufacturer, look no further—it takes some research. Determining if they’re the right partner or fit for you begins with the details. You’ll network with engineers, marketers, and investors, each eager to see you bring their designs to life. Discover innovative routes to bring your brand ideas to creation!

To feel confident that your visit will be a good one, bring an arsenal of various tools. Afterward, develop a plan that reflects your primary goals. Here, I outline the best places to go and how to begin your search, making each separate attempt as productive as possible.

1. Explore Online Directories and B2B Marketplaces

Web-based trade networks like Alibaba and Made in China are good tools to set the wheels in motion. These websites are great tools for finding thousands of different jewelry manufacturers. Explore our amazing jewelry made with 14K and 18K gold creations.

Browse fabulous gemstone jewelry with stunning semi-precious gemstones! Pietra provides you direct access to more than 5,000 private label jewelry products. Find out how you can locate suppliers that will allow you to create your own unique custom line!

Further refine the results by filtering for where the manufacturer is located, what kind of jewelry they make, and the production run size they work with. Look for these features:

- Detailed ratings and reviews from buyers

- Clear contact details and company profiles

- Product galleries and sample images

- Verified manufacturer status

- Lists of production specialties, like casting or stone setting

2. Attend Industry Trade Shows Globally

Trade shows are the best way to get a tactile sense of who’s out there and how they can serve you. Cities such as Las Vegas, New York, and most recently declared, Bangkok, crackle with electronic noise. Scintillating programming and events connect each one of these gifted artists, musicians, chefs, and creators.

Among them is Madison 501 Jewelry, with a unique look, an artistic go-with-the-flow soul, and cultural beauty that’s totally on-trend. Bring a checklist with:

- Booths from manufacturers who match your scale

- Makers who offer custom work

- Exhibitors with a documented history of getting behind small businesses and artisans

3. Seek Referrals and Network Actively

When you draw on your existing network, you open yourself up to referrals that you can count on and trust. Whether it’s through local maker markets, jewelry meetups, or online groups filled with other entrepreneurial faces, the connections help create a network of potential referral sources.

Here’s how to build your network:

- Join trade groups or business clubs

- Ask suppliers or peers for introductions

- Follow up with people you meet at events

4. Utilize Social Media and Forums

Instagram and Facebook are overflowing with jewelry makers, eager to share firsthand knowledge about how to find jewelry manufacturers. You’ll find vibrant communities of other designers showcasing newly produced work or creating content around their own production partners.

You can access communities such as the r/jewelry subreddit on Reddit and niche Facebook groups. These platforms allow you to efficiently crowdsource potential leads. The top platforms for this are:

- Instagram (hashtags like #jewelrymanufacturer)

- Facebook Groups for jewelry business

- Reddit forums focused on jewelry making

5. Research Local Manufacturing Options

Access to local stores can greatly shorten lead time for receiving goods and allow for deeper conversations to happen. Whatever your needs Madison 501 Jewelry has production capabilities both in New York City and in Thailand.

Here’s a quick breakdown:

| Feature | Local Manufacturer | Overseas Manufacturer |

|---|---|---|

| Cost | Usually higher | Usually lower |

| Quality | Easier to check | Varies, need samples |

| Lead Times | Shorter | Longer due to shipping |

6. Analyze Competitor Choices Indirectly

Study your successful competitors even in the jewelry industry. Discover the quality jewelry manufacturer behind their lines, styles, and stones by checking brand websites, trade show lists, and product tags to gather valuable insights.

- Who their key suppliers might be

- What materials and finishes are in demand

- How they handle custom or limited runs

Evaluate Manufacturer Suitability Thoroughly

Finding your perfect jewelry manufacturer takes a well-thought-out plan based on more than the lowest price or shortest lead time. Not just a bunch of independent contractors. For that, you need a partner equipped with the expertise and tools. Find a manufacturer who’s well-respected in their field.

If your main goal is saving money, just say so and make saving money your main goal above all other things. If supporting local makers through your jewelry purchase is your top priority, then set your standards first to reflect that. Here’s how you determine their suitability and properly protect your supply chain.

Assess Production Capabilities and Specialization

One can only truly learn by going below the surface and getting into the brass tacks of the techniques and materials used by each individual craftsperson. Inquire into their casting, hand-setting, finishing, or 3D printing process.

If you plan on sterling silver pieces with fine detail, check if they have the tools and workers for that. A good candidate should have practical experience working with stones, metals and finishes. These textures and materials will help you get pretty darn close to that desired palette.

Here’s a table to line up their skills:

| Manufacturer | Metal Options | Tech Used | Stone Setting Types | Finishing Choices |

|---|---|---|---|---|

| A | Silver, Gold | 3D printing, CNC | Prong, Bezel | High polish, Matte |

| B | Gold only | Lost wax casting | Channel, Pavé | Rhodium, Satin |

| C | Silver, Brass | Hand-crafting | Tension, Flush | Textured, Hammered |

Verify Quality Control Processes Rigorously

A qualified or experienced manufacturer should have developed methods or practices for checking and ensuring quality at each step. Ask what their quality assurance standards are, testing schedules and how they resolve defects.

Key things to look for:

- Proof of material testing

- Stone grading reports

- Steps for catching defects

- Final inspection records

- Warranty or after-sales support

Check Ethical Practices and Certifications

Good makers don’t just make things. They protect worker’s rights, ensure materials are responsibly sourced, and maintain full transparency. Look for RJC or ISO certifications, which can provide evidence of a higher standard for ethics.

A checklist for this stage:

- Responsible Jewelry Council (RJC) certificate

- Fairmined or Fairtrade gold and silver

- Conflict-free gem sources

- Environmental safety steps

Inquire About Lead Times and Capacity

You most assuredly don’t want any unexpected last-minute hang-ups throwing a wrench in your coordination game plan. Ask them what their lead time is from order to shipment, and if they’re able to meet your desired quantity order.

Check:

- Typical lead time for samples and main orders

- Minimum order quantity (MOQ)

- Flexibility in rush orders

- How they handle busy seasons

Review Communication Style and Responsiveness

A reputable manufacturer should be able to get back to you quickly and with full disclosure. Look for candid discussions and honest dialogue when needed. Look for a responsive team that is excited to get your feedback and iterations in.

Make sure you’re on the same page:

- Response time to emails or calls

- Contact person for your account

- Willingness to share progress updates

- Flexibility with special requests

Request and Evaluate Samples Critically

Ask for samples of work produced for other brands, or better yet, a custom example. Examine the overall metal finish, stone setting, weight and the way the piece appears under gemological magnification.

When you look at samples, focus on:

- Smoothness and finish of metal

- Stone secure and straight

- Clasp and hinge strength

- Markings for metal type or maker’s mark

Identify Potential Warning Signs Early

When navigating the jewelry industry, it’s crucial to be aware of red flags that may indicate a lack of reliability among potential jewelry manufacturers.

Keep an eye out for red flags that suggest a wholesale custom jewelry manufacturer will not produce high-quality products. Consistent poor communication and a lack of transparency in their manufacturing process is a huge red flag. Reviews from previous clients offer an honest look into the credibility of different jewelry manufacturers. Use this information to find the best jewelry manufacturer for your custom jewelry project.

- The rest are less clear, but some will be clear right off the bat.

- If you do find them, step away and think again.

- Slow or unclear replies

- No proof of quality checks

- Hidden fees or unclear quotes

- No proof of past projects

- Bad reviews or lack of references

Compare Pricing and Contract Terms

Sorting out pricing and contract terms is very important when it comes time to selecting a jewelry manufacturer. When you dig beneath the surface of these costs and regulations, you find out what you’re actually paying. It’s more than just the sticker price.

Get quotes from a variety of fabricators to get an idea of where their costs and fees land. Only then can you compare apples-to-apples, knowing what each one is offering up for your dollar. Beware of red flags like mold costs, transportation, and hustle charges.

These can be very subtle, very insidious, and very easily get away from you and 100% destroy your budget, so you need to know the whole story. Put all this information into a table. It uncovers in a fast, easy to understand way which jeweler is transparent about all fees upfront and which one tries to get you with hidden fees.

Comparing these numbers side-by-side is the first step to ensuring clear, honest conversations with the public.

Understand Different Pricing Models

How a maker decides to price their work might be a huge factor that shapes the trajectory of your whole project. Some will charge per unit, some per batch, some at an average of setup fees, or will average out design costs in inputs. Knowing these different configurations helps you decide how to align costs with your spending plan.

Having a unit price provides you with a clear, per-unit rate to reference for each item. The larger the quantity you order, batch pricing can often save you significantly. Most use tiered pricing schedules, where the more you order, the bigger a discount you receive.

A quick list of models you might find:

- Per piece pricing

- Batch or lot pricing

- Tiered pricing (price drops as quantity goes up)

- Flat setup or design fees

- Material cost plus labor

These decisions shuffle your money around and, in effect, decide how you shape the market with your own pricing.

Balance Cost Against Quality Offered

Every dollar you save has to economize away, rather than economize quality out of the program. Cheap work is wonderful until that cheap work meets your shiny new brand. Ask for samples, ask for reference photos, and conduct due diligence by reading reviews from past clients.

Use a checklist:

- Clean lines and settings

- Consistent metal finish

- Stone quality and fit

- Secure clasps and joints

- Warranty or repair terms

Keeping these legislative checks in place is what lets you keep your brand strong, and your consumers satisfied.

Clarify Minimum Order Quantities (MOQs)

MOQs are set by makers to make sure they’re covering the cost they need to. You do want to go quickly—you just want to find out if their policies and practices are in line with your dream and plan. You don’t want that if you’re starting small since a big MOQ can leave you with too much unsold inventory.

Worst of all, it can trap your working capital. Keep these points in mind:

- MOQ number matches your sales forecast

- Storage space needs

- Cash flow and upfront spend

- Room to test new designs

Line up MOQs with how you want to grow.

Negotiate Payment and Redesign Terms

Financial considerations and steps in the redesign process strongly influence how transparent and easy the process is. Define payment timeline, placement drops, deposits and what creates each invoice. Negotiate payment terms that give you enough time to confirm quality before paying in full.

Use a checklist for talks:

- Deposit percent due

- When balance is paid

- Redesign fees or limits

- Refund rules for rejects

- Delivery deadlines

These steps create mutual accountability and help both parties stay on the same page.

Initiate Contact and Build Rapport

The first step to identifying the best jewelry manufacturer for your business is the most important and it needs to be carefully crafted. How you choose to first reach out can set a strong standard for a successful, ongoing, mutually beneficial working relationship. By showing that you understand their needs and aren’t just interested in making a quick sale, you set the stage for trust immediately.

Choosing an experienced and well-equipped partner like MJJ Brilliant establishes a solid groundwork for a successful journey ahead. With glowing testimonials and decades of experience under their belts, they’re a no brainer. In doing so, you get a first mover advantage on Pietra.

Exterior and interior freelance designers can help you hone your concepts from the beginning stages. When you choose to get started, make your first outreach friendly and easy to understand. Moving forward in this fashion will help both sides more clearly understand the potential for a genuine partner approach to team.

Prepare Your Initial Outreach Message

A good opening note’s singular task is to hook the reader. This is a great opportunity to explain your brand’s big-picture idea and what you would like to get from a maker. Produce novel ideas and open doors to new opportunities and experiences.

Share what makes your brand unique, whether that’s using sustainable gold or having an aesthetic with daring jewelry designs featuring gem cuts. Get in touch if you need help with concept design, small batch or large run production.

Prove that you’re interested in learning about what they can do, and ask about what they’ve created before. Fellow creators like Madison 501 clan have over 70 years of collective design experience. Their immense talent and artistic eye truly shine when you ask them questions about their craft.

Here’s what to add to your message:

- Brand’s story, vision, and values

- Key details about your jewelry needs (materials, styles, quantities)

- Pragmatic expectation to learn the scope of their knowledge and past work

- Simple, honest intro about you and your brand

- Request for a quick call or next steps

Ask Insightful Questions Effectively

If you’re interviewing a designer, go in prepared with smart questions. This will make them feel confident that you know exactly what you’re after. Ask them how they might have guided their clients on projects like yours through the inescapable bumps in the road and turns in the journey.

Makers that have in-house, specialized staff can offer you peace of mind. At Pietra, you’ll even experience their amazing collection of 5,000 SHoppable private label products. Then, inquire about how they masterfully manage each stage, from design to shipping!

Use these questions:

- What’s your past work with pieces like mine?

- How do you check for quality?

- What’s your lead time for samples and full runs?

- Can you share past client reviews?

- What’s your process for addressing problems that come up?

Schedule Factory Visits If Possible

Nothing takes the place of walking into a real store and feeling the experience and energy of the space and the pulse and pace of shop life. Discover the handcrafted artistry on the macro, micro, and nano scale. Find out how the magic is made and meet the skilled artists and craftspeople whose hands it passes through.

This is critical to establishing good faith and sets the stage for negotiations to occur in a more collaborative way. When you go, look for these signs:

- Clean, safe workspace

- Staff who know their craft

- Tools in good shape and up to date

- Open talks about each part of the process

- Samples that show steady, high quality

Nurture a Strong Manufacturer Partnership

It’s truly been a wild journey on the jewelry business from idea conception to line introduction. Whether you’re creating fine jewelry or wholesaling fashion jewelry, your relationship with a great jewelry manufacturer is essential. It will have a profound impact on the whole state of manufacturing, from start to finish.

I’ve seen again and again that when you work together from the start, your designs receive the care and close attention they need. Particularly because first impressions on your line—especially when those first impressions are firming up future wholesale orders—carry so much weight, it’s important to be transparent and authentic.

I have been at it perhaps four times as long, the better part of four decades, guiding others through these uncharted waters. Here’s what I’ve found… the key to a successful custom jewelry design is building a strong, honest, trusting relationship with your manufacturer.

Whether a conversation is big or small, creating space for conversation and being action-oriented helps create change. The communication between you and your manufacturer should be ongoing and continuous. Engage in some heavy lobbying.

Communicate in detail what’s working, what needs to change, and where you want to go with your jewelry line. Communicate feedback quickly so everyone can keep up the positive momentum. When both parties don’t know what they’re working towards, the creative process turns into a vicious cycle of revisions, and ultimately subpar products.

Pick a manufacturer with experience in the style of jewelry you want to create. Whether you work in silver, gold, and diamonds, or aluminum, brass, and polymer, there’s a track for you! This helps you get the right skills and tools necessary to handle the production of your custom jewelry in-house.

Some best practices help keep a good partnership with your chosen jewelry manufacturing companies.

- Set up regular check-ins and updates.

- Offer feedback both ways, not just when the relationship is hurt.

- Stay clear about plans and changes.

- Respect time and effort on both sides.

Establish Clear Communication Channels

This is free advice, ACA, so buckle up. Will that be via email, phone, online chat, through apps like WhatsApp or Trello and so on? Set an agreed-upon frequency for check-ins, either weekly or at the end of each stage.

Here’s a quick checklist:

- Email for records and updates.

- Video calls for detailed talks.

- Shared folders for files.

- Messaging apps for quick questions.

Provide Detailed Design Specifications

Thoroughly designed specs are essential in helping bring your vision to life. Share production-ready outline drawings, CAD files, or high-res examples. Add your ring metal, stone color and carat, and finish you would like to work with.

Here’s what to include:

- Size and weight in inches and ounces.

- Metal and stone types.

- Plating or finish.

- Drawings or digital files.

- Packing wants.

Maintain Transparency and Mutual Trust

Setting clear expectations and being transparent about the process helps establish trust. Let us know what moves you and what motivates you to create! Ask your manufacturer to add their input too.

Trust grows with time and through these steps:

- Speak up about issues as they come.

- Welcome advice from your manufacturer.

- Share updates on both sides.

- Keep records of talks and changes.

Conclusion

To land the perfect jewelry manufacturer, you’ll first need clear goals, thorough due diligence, and to take a few protective measures. You locate competitors, develop leads, and rate what every manufacturer is suited to making.

You flip through catalog pages in dollar value, negotiate with the top dogs, and establish credibility right off the bat. You do your homework with samples and you view their color range.

From there, you closely watch to see how they do business. You double check to ensure all their castings are solid and all the stones are properly seated into their prongs.

We love your no-bull approach to storytelling—even when you’re calling it on your own brand’s needs. To make sure you end up with a great fit, keep those lines of communication as wide-open and continuous as possible.

Interested in producing your very first collection, or taking your business to the next level? So go network, ask questions, and seek your next opportunity with a fervor that will achieve much more than you ever expected.

Frequently Asked Questions

How do I choose the right jewelry manufacturer for my brand?

Get specific about what your brand needs in order to work with a reputable jewelry manufacturer. Confirm that their style, capabilities, and minimum order quantities match your artistic vision.

Then, look for custom jewelry manufacturers who have a well-documented history of working within your niche and received positive feedback from past clients.

Where can I find reliable jewelry manufacturers?

Search for possible jewelry manufacturers through established platforms like Alibaba, ThomasNet, or industry trade shows.

Look at recommendations from other jewelry entrepreneurs who have found good jewelry manufacturers or such as the American Gem Society.

What should I ask a potential manufacturer before signing a contract?

Ask for their minimum order quantities, production turnaround times, pricing structure and quality control processes.

Inquire as to whether or not they are able to produce custom jewelry designs.

Ask for samples to make sure their quality is up to your standards before choosing a manufacturer.

How can I ensure product quality from my manufacturer?

Request product samples from potential jewelry manufacturers, ask whether they possess relevant certifications, and look for third-party reviews or testimonials.

Regular communication and explicitly stated quality standards help guarantee high, consistent product quality.

Is it better to choose a local or overseas jewelry manufacturer?

Plus, local custom jewelry manufacturers make communication easier and shipping faster.

Overseas options usually offer a much lower cost per unit. They entail longer lead times and cultural differences that can produce their own hurdles.

What are common contract terms to review with jewelry manufacturers?

Clarify all details with potential jewelry manufacturers, including pricing, payment plans, minimum order requirements, production timeframes, protection of intellectual property, and return policies. Have everything in writing, including details of jewelry manufacturing.

How do I build a strong, long-term relationship with my jewelry manufacturer?

Keep every line of communication open with your custom jewelry manufacturer. Be prompt in communication and payment to establish trust and respect. It’ll serve you well and help lead to a productive partnership.

share this recipe:

Still hungry? Here’s more

Custom Engraved Jewelry Wholesale: Adding a Personal Touch

In today’s competitive retail market, standing out is everything. Consumers are no longer just buying

Choosing the Right Jewelry Clasp for Custom Designs

Introduction When designing custom jewelry, the clasp is often the unsung hero – it’s the

How to Dodge Jewelry Sourcing Risks from China: Your 2026 Playbook

The allure of jewelry sourcing from China is undeniable. It’s a global hub of manufacturing,

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.