Services We Offer

Jewelry Factory: HonHo's 15+ Years of Expert Manufacturing Excellence

As Asia’s leading jewelry factory and manufacturing partner, HonHo delivers beyond conventional production capabilities. We provide a comprehensive suite of services designed to elevate your jewelry manufacturing experience.

Featured Services

3D Design Excellence

Transform your jewelry concepts into precise digital reality at our state-of-the-art factory. Our advanced design capabilities meet the demanding pace of modern jewelry manufacturing while maintaining the artistic integrity your brand deserves. The jewelry factory‘s design team works closely with you to ensure every detail meets your specifications.

01

02

Sampling Services

Our factory offers comprehensive sampling services to give you a taste of how we can elevate your brand to the next level. Simply provide us with your information and design documents, and our jewelry factory craftsmen will create stunning samples to win your trust and confidence before proceeding to full production.

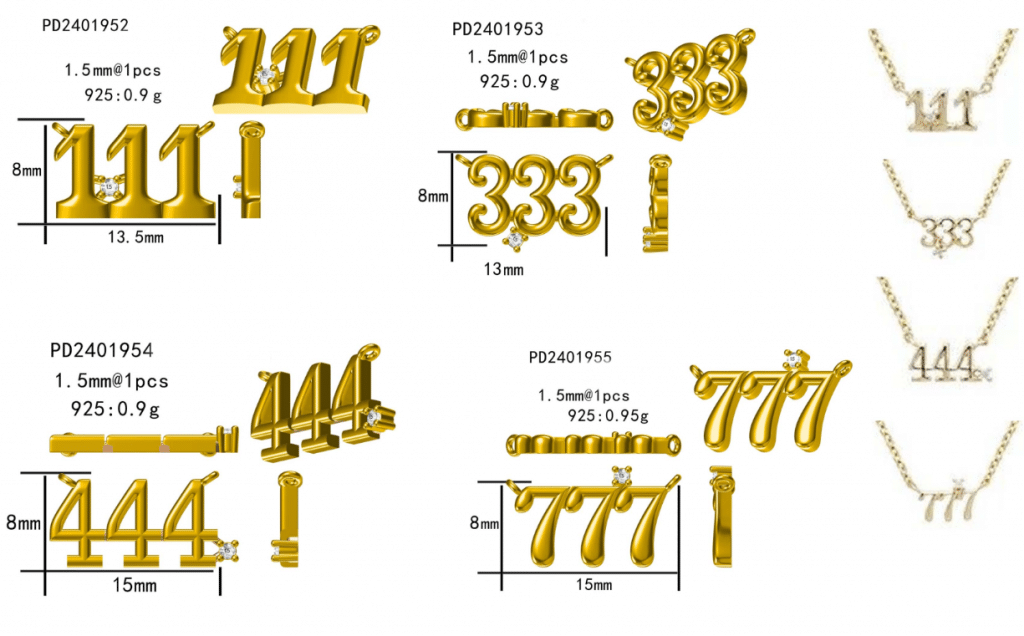

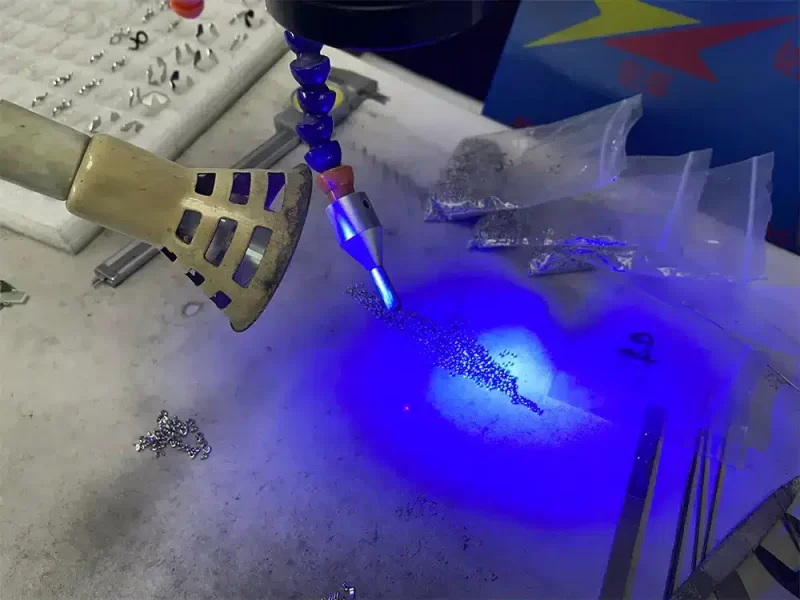

Lean Manufacturing Solutions

Our factory‘s advanced digital manufacturing process meets the demanding pace of modern jewelry wholesale. Using cutting-edge CAD/CAM technology and industry-leading design software, our jewelry factory delivers precision-engineered pieces that exceed traditional handcrafting limitations. Our streamlined workflow ensures accurate, consistent, and scalable production while maintaining the highest quality standards expected from a premium jewelry factory.

03

04

Traceable Quality Control Practices

In today‘s competitive jewelry wholesale market, our jewelry factory has implemented comprehensive quality tracking systems that ensure excellence at every production stage. Our state-of-the-art digital quality control processes combine advanced software solutions with detailed documentation, providing complete transparency from design conception to final product delivery. This meticulous approach makes our jewelry factory a trusted partner for brands demanding consistent quality.

Brand Packaging Solution

Elevate your jewelry brand with our jewelry factory‘s premium packaging solutions. We offer customizable, eco-conscious packaging designs that protect your pieces while enhancing your brand identity. From elegant boxes to sustainable materials, our jewelry factory’s comprehensive packaging service ensures your products arrive in style, reflecting the quality craftsmanship within.

05

06

Private Label Service

Transform your jewelry brand vision into reality with our jewelry factory‘s comprehensive private label service. Our advanced design technology and expert team deliver custom jewelry solutions that meet your exact specifications while maintaining your unique brand identity. As a full-service jewelry factory, we handle everything from initial concept to final production, allowing you to focus on building your brand.

4 Key Benefits of Working with a Professional Jewelry Manufacturer

- 🌟 Production Excellence

Optimize your investment through direct manufacturer collaboration. Our streamlined production process eliminates middleman costs and complex international sourcing barriers, delivering premium jewelry at competitive prices.

- ⚡ Seamless Efficiency

Focus on expanding your business while we handle the manufacturing details. Our experienced team manages the entire production cycle, ensuring timely delivery and consistent quality for your collections.

- 💎 Manufacturing Mastery

Benefit from our decades of jewelry manufacturing expertise. Our collaborative approach helps transform your creative concepts into market-ready collections that capture your unique brand identity.

- 📈 Business Growth

Enhance your market position with our precision-crafted jewelry. HonHo’s commitment to quality and innovative design capabilities helps your products achieve competitive advantage in the global marketplace.

Industry Insights from Our Jewelry Factory Experts

The jewelry manufacturing industry continues to evolve rapidly. At HonHo jewelry factory, we stay ahead of trends by investing in the latest technology and sustainable practices. Our jewelry factory regularly publishes insights on manufacturing innovations, material developments, and market trends to keep our partners informed and competitive in the global jewelry market.

Work with HonHo on the Custom Jewelry Business!

- Jewelry Brands

- Jewelry Wholesalers

- Retail Shops

- E-commerce

- Starting-up Brands

- Celebrities