Top 10 Low MOQ Jewelry Manufacturers You Should Know in 2025

A low MOQ jewelry manufacturer provides an excellent opportunity for any brand or seller to order jewelry in smaller quantities. This often begins with as little as 50 or 100 pcs.

However, for many small businesses, these makers represent an easy way to prototype a design or reduce the start-up cost. Many have customizable features such as custom logo design, quick turnarounds, and assistance with materials including gold, silver, or stainless steel.

Find out how these suppliers are helping emerging brands get off the ground and stay under MOQ in our following articles.

What is Low MOQ Jewelry?

Low MOQ jewelry means that you can buy in very low quantities per piece. This is drastically lower than most wholesale standards! This model is honestly a game changer for small businesses and startups.

It allows you to keep a handle on your costs while creating thrilling new avenues for expansion! Being able to order small batches gives new brands the confidence to try ideas. They’re able to see what’s selling without putting too much money at stake.

In the quick, hard-hitting marketplace of today, low MOQ makes room for many more experiments and tests. This flexibility is especially important for creative teams and independent designers.

Defining “Low” in Jewelry

Low MOQ in jewelry usually refers to 20-30 pieces minimum per SKU. For many makers this is still a minimum of 100 pieces or more.

For instance, sterling silver jewelry could require a $5,000 initial order, though this is a big drop from the former industry norms. What qualifies as “low” varies by material—gold, silver, and steel all cost and take different amounts of time.

Brands such as HonHo Jewelry Manufacturer in China focus only on stainless steel, brass, and 925 silver. They don’t stop there, offering low MOQ for custom jewelry, waterproof jewelry, and even gold-filled jewelry.

They provide finishes such as gold vermeil, rhodium, or rose gold plating, allowing even low MOQ jewelry to stand out.

Why It’s a Game-Changer

Low MOQ fundamentally shifts the relationship between shops and makers. With low MOQ orders, there’s little to no waste and you can keep the designs fresh.

New concepts can be easily tested quickly, with lead times of two to four weeks. This fast cycle democratizes the field, allowing more players and creating more choices.

Who Benefits Most from This?

Small business owners, indie designers, and new brands benefit from low MOQ. Established boutiques use it to bring in new looks more frequently, while emerging designers can test their concepts with lower stakes.

A convenient, low-stakes alternative is what allows each of them to rise above the rest.

Key Low MOQ Sourcing Benefits

Low Minimum Order Quantity (MOQ) sourcing transforms the way both new and established brands launch jewelry collections. Retailers and creators have the ability to test new concepts through lower MOQs. This strategy reduces their initial investment and prevents them from tying up their cash flow.

Sourcing from low MOQ manufacturers such as HonHo Jewelry makes the process much easier. We have more than 15 years of expertise in stainless steel, brass, and 925 silver jewelry production, allowing them to create custom, waterproof, and non-tarnish products without large MOQ. This strategy has allowed both large corporate brands and independent smaller designers to be more agile.

Test Ideas, Minimize Risk

Low MOQs allow companies to produce limited runs of new jewelry styles. For instance, a fashion jewelry designer might need to order 50 units of a new bracelet design rather than the current norm of 500. This allows you to gauge customer response before committing more time and money to the project.

Craft and DIY Shops can take advantage of this opportunity to get feedback on color, style or size and then perfect the product. This methodical, step-by-step approach greatly reduces the chance of excess inventory and helps to prevent waste.

Better Cash Flow Management

Purchasing smaller lots allows businesses to spend less of their capital on inventory. This means they can invest more money into expanding their marketing or other development initiatives. When demand changes, such as during holiday seasons, stores can order what they need without getting stuck with extra inventory.

This aligns nicely with real world sales cycles and contributes to keeping businesses cash flow positive.

Access for New Designers

Low MOQs make it possible for new designers to get started. New designers are often able to create original concepts that don’t require a huge amount of money up front. In doing so, they get to engage directly with established factories.

This frees them to explore their creativity. Building relationships with partners such as HonHo Jewelry, who encourage both small and large MOQs.

Quicker Market Entry

Because of low MOQs, brands have an advantage in getting new collections out quickly and responding to trends in real time. Low MOQ orders allow them to grab more seasonal looks, or a new trend that emerges, quickly without long lead times or large investments.

This rapidity allows companies to remain a step ahead in a crowded marketplace.

Choose Your Low MOQ Partner

Choosing the right low MOQ jewelry partner is one of the most important decisions brands and entrepreneurs make. It helps them experiment, prototype, and allows them to run a lean startup more efficiently.

The truth is, markets are moving quickly! Your ideal partner will make you more nimble, lower your risk, and prevent you from getting cash tied up in extra inventory. This iterative process requires deep consideration of your business goals, the manufacturer’s capabilities, and where the two intersect.

Let’s explore the key takeaways to help you make your search targeted and realistic.

1. Define Your Exact Needs

Before reaching out to a custom jewelry manufacturer, it’s crucial to develop a solid understanding of your custom jewelry needs. Be specific about the style of jewelry you wish to produce, detailing your materials such as 925 sterling silver, 14k/18k gold, or stainless steel. Additionally, outlining your product concepts and intended audience will help define what makes your unique jewelry stand out in the jewelry industry.

Creating a checklist of essential features, including options like waterproofing and tarnish resistance, can streamline your search for the right jewelry manufacturer. The clearer your vision, the better your chances of finding a manufacturer that aligns with your objectives and can support your jewelry business effectively.

This clarity not only aids in comparing suppliers but also prevents project delays. By being specific about your needs, you increase the likelihood of identifying a reliable manufacturer who can bring your jewelry line to life with exceptional craftsmanship and quality products.

2. Research Potential Suppliers Thoroughly

Don’t choose the first supplier you come across. Expand your search and consider multiple suppliers. Check out their websites to get an idea of what types of products they manufacture.

Look for evidence that they’ve successfully worked with the materials and styles you need. These could be vintage-inspired styles in gold vermeil or modern creations in brass!

Look at the supplier’s reviews and testimonials from other clients to gauge their reliability and product quality. This is something that really hurts most small businesses—nearly 80%, according to industry reports—when it comes to dealing with suppliers, particularly at low MOQs.

Due diligence can save you from wasting time, money, and effort in the long run.

3. Verify Credibility and Experience

Experience is key, particularly when your order is low and margin for error is slim. Research every potential manufacturer’s track record in the industry.

Research how many years experience they’ve had working with metals like silver, gold or stainless steel. Inquire if they can provide references from previous clients.

Certifications and compliance with standards — whether it’s ISO, ITAR, or ethical sourcing labels like Fair Trade — adds an extra layer of trust. A partner that understands the details of tarnish resistance or advanced plating techniques will be more equipped to deliver superior outcomes.

HonHo Jewelry Manufacturer has more than 15 years experience in the field. Their core materials are stainless steel, brass, and 925 silver—proof of their profound know-how.

4. Assess Communication and Support

We can’t stress this enough—good communication is the key to a successful manufacturing partnership. Gauge response time with early inquiries to see how responsive suppliers are to initial questions.

Are they prompt and informative in their responses, or do they just raise additional queries? Continuous communication and ongoing support from your low MOQ partner is critical during design modifications, sample approvals, and production runs.

Find a partner that communicates clearly and directly, keeps you up to date on what’s happening, and is available when something goes wrong. This goes beyond simply avoiding an error—this is the first step to establishing a strong business-to-business relationship that will endure.

5. Understand Their Quality Control (Our Tip: Ask About Low vs. High Volume QC)

Quality control doesn’t end at large orders. Inquire with each potential manufacturer about their approach to quality control for low-MOQ orders—do they use different quality standards than high-volume production runs?

Some will have one QC process established for samples and another for full-scale production. Demand clear answers on what they’re doing. Regular quality assurance inspections will give you peace of mind that your products won’t disappoint, regardless of if you order a batch of 50 pieces or 500.

Inquire about their inspection process, plating thickness test, or ask how they claim they will manage waterproofing.

6. Inquire About Customization Flexibility

In fact, customization is one of the biggest reasons brands partner with low MOQ partners. Find out from potential suppliers how much they’re willing (and able) to accommodate bespoke designs, special finishes, or blended materials.

Are you able to design a signature clasp or order a certain color of gold fill? Having an open dialogue regarding available options for custom orders will ensure that you can bring your most creative ideas to life.

Some manufacturers, such as HonHo, focus on producing custom waterproof and non-tarnish jewelry. This is an awesome brand-defining quality for a brand that’s all about lasting and day-to-day wear!

7. Clarify All Cost Factors (Our Tip: Uncover Hidden Fees)

Being upfront about cost factors is critical for small businesses. Request a full cost breakdown for your order—including mold costs, setup fees, and plating options.

Manufacturers will often throw in fees for additional samples, expedited shipping, or custom finishes. If you are working with overseas partners, be mindful of currency fluctuation.

Having all inclusive details itemized in writing prevents unexpected surprises at the last minute and allows you to compare true costs between suppliers.

8. Discuss Turnaround and Logistics (Our Tip: Impact on Small Orders)

Turnaround times for small batches should be significantly less than for order flexibility with large orders. The sweet spot for turnaround on low MOQ is typically 2-4 weeks, but it depends.

Discuss with suppliers what their lead time will be to produce and ship your order. Find out from them what couriers they use as well as what level of tracking is provided.

Are less profitable, smaller orders treated with equal interest and care? In some cases, smaller runs are slotted in between larger orders, affecting when they will deliver.

Be sure to set expectations upfront and agree on timelines before you say yes.

9. Negotiate MOQs Smartly (Our Tip: A Win-Win Approach)

Don’t forget that negotiation is normal and reasonable. Don’t promise more than you can deliver right away, and inquire about flexibility.

Some suppliers will have a sliding scale—lower MOQs at a higher per-piece cost, for instance. This gives you the flexibility to experiment with fresh concepts without having to put a lot of money on the line.

Develop a relationship. Develop long-term business relationships—don’t go for the nuclear option and demand the lowest number right away. Manufacturers will sometimes give more favorable terms for clients who return consistently or for brands that have a clear strategy to grow.

Custom Jewelry with Small Orders

On demand jewelry allows brands and designers to experiment with more bold concepts. It gives them the ability to test trends and get new looks into market without a huge upfront outlay. Low MOQ jewelry makers also give companies the means to produce exclusive pieces that represent their brand and mission.

They allow you to fulfill your clients’ desires and needs while minimizing risk. These nimble configurations are crucial for upstart brands, small batch labels, and anyone looking to break through the noise with unique custom looks. Custom orders in small batches usually require a lot of individualized collaboration between the brand and maker to ensure each little detail is perfect.

Look for a track record of the maker and where their materials come from. Check their quality controls—look for ISO 9001 or Responsible Jewellery Council membership. Though smaller orders may be higher cost per piece, the return on investment in brand recognition and customer retention is obvious.

Bring Unique Visions to Life

Custom jewelry is all about imagination. Very low MOQs create the ability for designers to experiment with adventurous shapes, metal combinations or new stones without breaking the bank. Say a designer wants to combine some stainless steel with the 925 silver.

Or they can experiment with gold vermeil for a limited edition line! When creating with a collaborative team, it’s often more convenient to receive feedback and iterate designs. We’ve seen that when you work with HonHo Jewelry Manufacturer in China, you return with pieces that fit your initial vision.

Material and Technique Insights (Our Tip: What Works for Small Batches)

Small batches metal material and technique tips. Our favorite metals for small batch production are brass, stainless steel, or 925 silver. They are durable, pliable, and economical.

Whether it’s hand-setting your stones or using gold-filled plating, there are ways to maintain quality should you decide to take the plunge. Experimenting with waterproof or non-tarnish finishes is a good idea for long-term attractiveness.

Prototyping Without Breaking Bank

Low-MOQs allow brands to push new designs as samples without making a 5-figure spend. This allows them to see physical pieces, receive customer feedback, and adjust the design prior to creating a big production run.

It saves you from making expensive blunders and produces a more resilient end piece.

Research Manufacturer Reputation

Doing some basic first due diligence by searching a jewelry manufacturer’s name out in the world can help you avoid these hidden dangers.

Research Manufacturer Reputation Search for reviews and case studies from other brands that have utilized the manufacturer’s low moq jewelry service. Look for whether they post pictures of actual projects or provide details on completed orders.

A reputable manufacturer will have displayed completed works, provided a clientele list, or be able to provide documentation of timely deliveries. Further, look to see if the firm is a member of any trade associations, as this can indicate better quality of work and practice.

Schedule a time to talk with them over the phone, email or video conference. It gives you a window into their communication style and their approach to handling difficult questions! Taking this step will go a long way in identifying the makers who align with your needs and values the best.

Essential Factors for Manufacturer Selection

When selecting a low MOQ jewelry manufacturer, people are looking for so much more than just low MOQs. Another useful consideration is placing an emphasis on production quality. Look for a manufacturer that employs solid metals and stones.

Request samples whenever possible. Many manufacturers will have a library of samples for you to peruse. Like the experience you’ll have working with them, it counts how quickly and transparently they communicate with you.

This demonstrates whether or not they are able to address issues rapidly. Inquire about their commitment to safe working conditions and fair compensation. Many green jewelry buyers demand eco-friendly practices in jewelry production.

Manufacturers that utilize lower waste or recycled materials are more impressive. In addition, consider the location of the manufacturer. When local, shipping is cheaper and quicker. All of these things make it easier for buyers to collaborate with makers they trust and can develop with.

Avoid Common Selection Mistakes

Selecting a low MOQ jewelry manufacturer can seem straightforward enough. Little steps can become giant issues if not treated properly. The first and biggest mistake is choosing a supplier simply for low moq jewelry manufacturing.

Though that’s a positive for small brands, it’s important to ensure that you vet the maker’s artistry, quality control processes and production history. Request several sample pieces and examine for finish, weight, and the setting of stones.

Many buyers throw caution to the wind and skip essential steps, such as reading past reviews or requesting certifications. Some fail to consider how the manufacturer communicates when there is a production or shipping delay, leading to avoidable anxiety down the road. By receiving information to verify these aspects, brands can minimize the risks. This initiative establishes a mutually beneficial, long-term relationship.

Importance of Selecting the Right Manufacturer

Selecting a low MOQ jewelry manufacturer sets the tone for the entire business relationship. The right manufacturing partner will provide consistent quality, open communication, and transparent pricing from the beginning.

For niche brands or early-stage startups, low MOQs give flexibility to test concepts and limit upfront inventory investment. Reliable manufacturers provide accurate lead times and collaborate with you on custom designs and pieces.

They provide a wide variety of designs, materials, and textures. This allows them to easily make design adjustments or experiment with new popular trends. A capable manufacturer takes smart labor practices and environmentally conscious approaches — important to today’s consumers — to the next level.

When choosing, seek out consistent quality, transparent pricing, and genuine reviews from previous customers. These two signs indicate that you can put your brand’s name on the line and trust them with it.

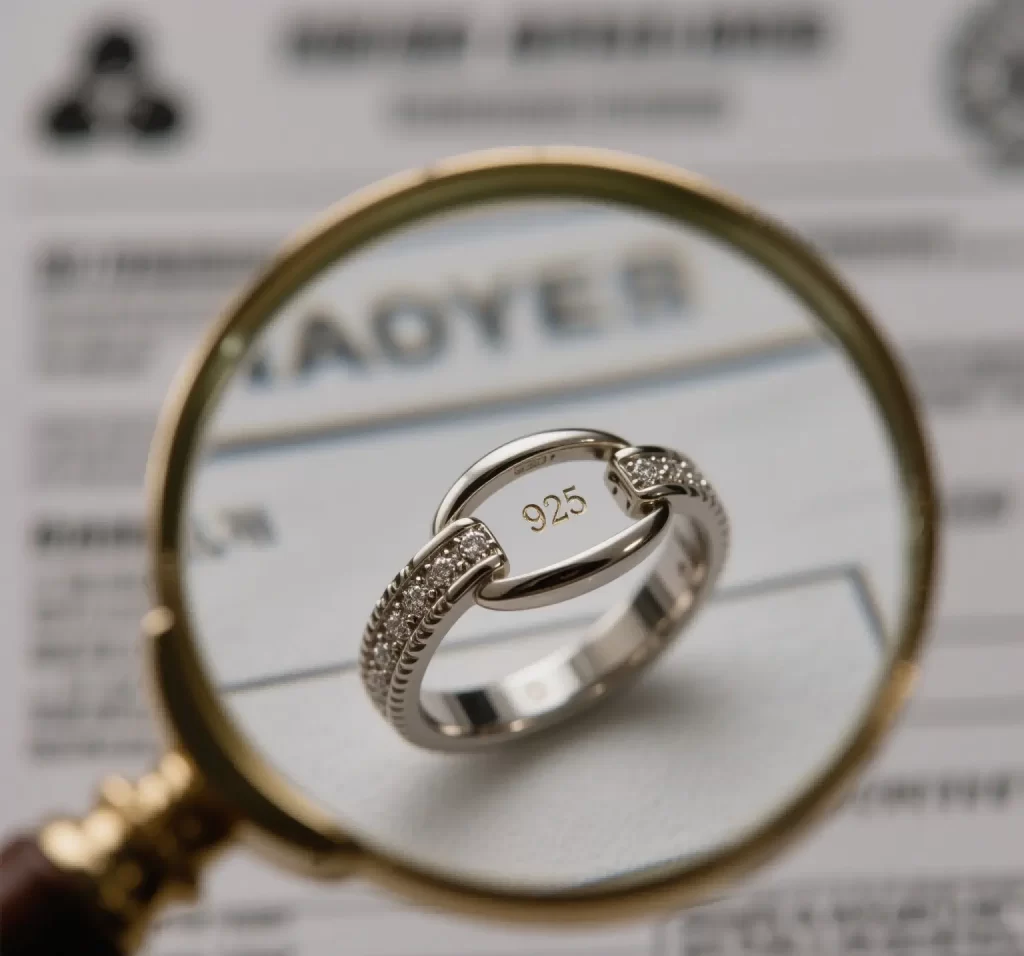

Verify Quality Standards

Verify Quality Standards Quality control must be a priority when working with low moq jewelry manufacturers. Buyers who are diligent will inquire how the manufacturer conducts their metal testing for purity. They want to see marks such as 925 sterling silver or gold plated.

Quality makers will provide detailed pictures and short video clips to get a sense of the finish, stones used, clasps and so on. A few provide low-test orders—such as five to ten units—which allow you to verify weight and polish in detail. Inquire whether they adhere to ISO standards or comply with regulations for safe metals such as lead-free or nickel-free metals.

Additionally, makers who present lab reports or provide third-party test results help establish trust. Keep an eye out for imprecise documentation on previous orders. This can often help detect any problems with the color, stone or setting before purchasing.

Ask Important Questions

When searching for a reliable jewelry manufacturer, it’s crucial to consider more than just the cost of low MOQ jewelry manufacturing. You should aim to understand their low MOQ jewelry offerings and ask about essential factors such as lead time, sample costs, and quality checks. Not every factory will be transparent about their low MOQ options, which can impact your jewelry business.

Additionally, ensure they can create custom jewelry needs tailored to your specifications and inquire about their expertise with various metals and stones. Obtaining production samples is vital; do they accurately reflect the images provided?

If you plan to expand your reach internationally, confirm that they adhere to international safety standards, particularly concerning nickel or lead content. Gaining clarity on these aspects early can help you avoid delays and unexpected costs in your custom jewelry production.

Overcome Low MOQ Challenges

While low MOQ jewelry manufacturers are a blessing that opens doors for small brands and startups, they come with their own set of challenges. Small businesses or companies creating new lines often don’t need thousands of labels or custom packaging.

Suppliers sometimes impose low MoQs to make sure their orders are economically feasible given the time and expenses required. The reality is that different manufacturers and different products have widely varying MOQs, so there’s no one size fits all. Identifying that right fit is extremely important!

Intelligent planning, transparent communication, and adaptive purchasing tactics keep your inventory and expenses in check and limit your risk.

Tackle Potentially Higher Unit Costs

Low MOQs usually come with potentially higher unit costs, as manufacturers do not benefit from the cost advantages of producing in bulk. To overcome potentially higher unit costs, companies can often find alternative materials or design aspects that increase efficiency while maintaining or improving the quality.

By replacing solid gold with stainless steel we are able to keep the cost affordable. HonHo Jewelry is a great example of this, providing value with their waterproof, non-tarnish brass and 925 silver offerings.

Joint orders, in which two or more brands join together to make a purchase, assist in fulfilling these greater MOQs and decreasing unit costs.

Find Truly Reliable Partners

Willingness to put in the work Trust is essential when you’re dealing with low MOQ suppliers. Not all manufacturers will be amenable to small runs, so it pays to cultivate deep connections with those who will.

Connections, trade shows and online reviews can help identify truly reliable partners. Creating a partnership by working with multiple suppliers increases flexibility and decreases the risk in the event that a partner is unable to fulfill your needs.

Manage Lead Time Expectations

Both how big an order is and the complexity of what’s being made will play a role in lead time for having completed jewelry. Communicating clearly about production times from the start, and keeping lines of communication open throughout, helps ensure expectations are equitable.

This ensures that even with low orders, projects continue to move along and stay on schedule.

Ensure Consistent Quality (Our Tip: Specific Checks for Small Runs)

When working with low MOQ orders, every nuance counts. Establish concrete quality standards, such as requiring pre-production approval of a sample or pre-production photos, to ensure quality remains high.

Ensuring every single piece hits the brand’s mark is critical.

Manufacturer’s View: Setting MOQs

Manufacturers set minimum order quantities—known as MOQs—to ensure that production will run smoothly and keep costs down. To a jewelry maker, the MOQ’s picture can be completely different. Some manufacturers set it at 10 units, others at 200 or as much as 500.

These figures are predicated on their cost of machine setup. They can depend on the materials you are using and the way your print shop is set up. There’s not a hard and fast guideline. Every maker determines an MOQ that makes sense for their capacity, expertise and what the market is looking for.

Production Efficiency Realities

The primary culprit behind MOQs is simply efficiency of production, both in terms of speed and quality. It can be much more expensive to produce a handful of rings or necklaces at a time. This is due to the fact that each run requires a setup—changing tools, prepping machines, and ensuring everything is correct.

If only ten pieces are produced, that cost is distributed over a smaller number of units. A little workshop could set an MOQ of 50 pieces, for instance. This allows them to recoup setup costs and still earn a profit.

It gets worse—factories that are bigger with more machines may require a MOQ of 1000 or 500 pieces to cover their costs. The ultimate goal is to have each run flow seamlessly and maximize utilization of time, labor and materials.

Material Sourcing Constraints

Sourcing specific metals, stones, or clasps in smaller quantities can prove difficult. Most suppliers only offer raw materials at a wholesale level. If a jeweler wants to make only 20 bracelets, they may have to buy more silver or gems than needed.

This increases expense and waste. Some factories raise MOQs simply to ensure that they will be able to source all the components for a new design. Understanding the current state of the supply chain makes it easier for buyers to understand why MOQs are an issue.

Balancing Client Needs and Viability (Our Tip: Why They Set Them)

So yes, manufacturers want to honor small brands’ requests. They need to make sure their business is sustainable. Low MOQs allow newer brands to test ideas and concepts without a large financial commitment.

Makers need to be mindful of expenses and square footage. Holding a lot of dead inventory or purchasing goods that go unused is not profitable. Quality makers collaborate with clients and determine appropriate MOQs together that serve both parties.

This frank conversation leads to stronger collaborations and more equitable pricing.

Conclusion

Low MOQ jewelry manufacturers bring increased variety and improved access to market for emerging brands and developing retailers. They allow you to sample new styles, establish buyer confidence, and reduce risk. No matter the size of your brand, there’s always an opportunity to expand with low moq jewelry.

Check out how many contemporary artisans are leveraging new creative tech to forge their own looks— and yours. Not only do they give precise instructions, even on narrow runs! Watch out for vague language, slow response times, and at the very least, a test run to ensure consistency in supply.

To maximize the potential of your concepts, collaborate early and often with your manufacturer and communicate your goals. Don’t be afraid to make adjustments or introduce new trends. To learn more advice, or for our complete guide to choosing a low MOQ jewelry manufacturer, stay tuned to our subsequent blog posts.

Frequently Asked Questions

What does low MOQ mean in jewelry manufacturing?

Low MOQ, or low minimum order quantity, allows small jewelry businesses to order custom jewelry in low quantities, often as few as 10-100 pieces. This flexibility is ideal for those looking to launch a unique jewelry line without the need for large bulk orders.

Why should I choose a low MOQ jewelry manufacturer?

With low MOQ custom jewelry manufacturers, you can test unique jewelry designs before going all-in, allowing small jewelry businesses to scale without a significant initial investment while minimizing financial risk.

Can I customize jewelry with low MOQ orders?

Can I get custom jewelry made with a unique design and low MOQ orders? You can customize specific materials, styles, or branding, all while keeping a low MOQ.

Are low MOQ jewelry manufacturers trustworthy?

Pay attention to reliable jewelry manufacturers with real reviews, good communication, and sample production services. Select partners that have shown expertise in custom jewelry needs.

What challenges might I face with low MOQ orders?

What challenges might I face with low MOQ orders in the custom jewelry manufacturing industry? Proper planning and open communication can help avoid these problems.

How do manufacturers set their MOQs?

Manufacturers often determine their MOQs based on the ability to cater to smaller clients, which can affect their custom jewelry production costs while ensuring quality craftsmanship in their jewelry line.

Is low MOQ jewelry suitable for all types of businesses?

This makes low MOQ custom jewelry perfect for emerging brands, small jewelry businesses, or anyone looking to dip their feet in a new market. Bigger companies will often drive up MOQs to get more competitive pricing.

share this recipe:

Still hungry? Here’s more

Top 50 Jewelry Brands Worth to Buy 2026: The Definitive Investment & Style Encyclopedia

The global jewelry market in 2026 is a fascinating landscape where centuries-old heritage meets cutting-edge

Why Brass Jewelry Wholesale Fits Fashion Brands: The Strategic Guide for 2026

In the rapidly evolving landscape of the global fashion industry, the demand for affordable luxury

Enamel Jewelry Wholesale: Adding Color to Your Brand’s Collections

In the ever-evolving world of fashion, color has become the ultimate tool for self-expression. For

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.