The Ultimate Guide to Finding Your Custom Earring Manufacturer

The Ultimate Guide to Finding Your Custom Earring Manufacturer

Sick of gaudy jewelry drowning the market? You have unique methods to create earring designs that you wish to make a reality today but don’t know how to begin? You can take your product from ordinary to extraordinary by partnering with the right custom earring manufacturer who has the necessary skills to weave magic into metal.

The Institute offers custom earring manufacturers an opportunity to provide retailers with a way to compete in the salmon market today. This 101 guide walks you through each step and every consideration in finding your manufacturer, evaluating them and building a relationship with them that can make your creative vision a reality.

Whether you’re searching for a reliable earring manufacturer, specialized earring supplier, or established wholesale earring suppliers, this guide will help you navigate the complex landscape of jewelry manufacturing.

Know What You Need (Before You Search)

Your Earring Specs To Specification

What do you want before you start looking for a custom earring manufacturer?

- Materials: Consider whether you want precious metals, such as gold and silver; inexpensive alloys; or alternative materials, such as resin or wood. Each material needs various expertise and equipment.

- Design Complexity: Are you making basic studs or complicated dangling earrings with many different moving parts? Other manufacturers specialize in certain styles.

- Target Audience: Are they luxury, mid-range, budget? The manufacturing decisions you will make will be dictated by your target market.

- Quantity Requirements: Do you require very small batches for a boutique collection, or for larger runs for wholesale?

- Standards of Quality: What kind of craftsmanship and finishing are you looking for in your products?

Defining Your Business Needs

When communicating with potential earrings wholesale suppliers, being specific about these specifications will help you find the perfect manufacturing partner. In addition to the physical product, think about your wider business needs:

- Branding elements: Custom packaging, tags or specialty finishes that nurture your brand identity.

- Intellectual Property: In terms of prototyping, what can be done to protect your designs during the manufacturing process?

- Timelines: What are your production deadlines and lead times?

- Budget Limitations: Set your financial limits for your manufacturing partner.

- Long-term Goals: Are you looking for a one-time production run or a lasting manufacturing relationship?

What to Check: Where to Look

These platforms are excellent resources for finding both custom earring manufacturers and wholesale earring suppliers who can meet your specific requirements.

Online Search Engines

Here’s how to find your custom earring manufacturer online, beyond the generic terms:

- For example, search for something more specific, such as “sterling silver custom earring manufacturer USA” or “small batch brass earring manufacturer”

- Use advanced search operators to focus results

- Look past page one of results, as some great manufacturers may not have maximized their online presence

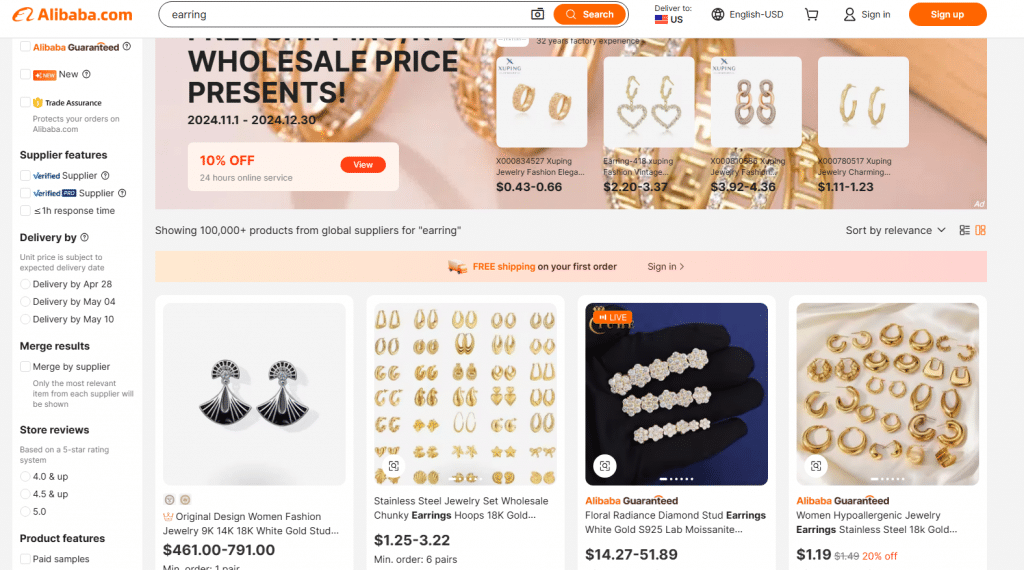

B2B Marketplaces

Platforms such as Alibaba and Global Sources can provide valuable resources, but only if you know how to navigate them strategically:

- You reverse key in validated, years in business, and minimum order quantities

- Differentiate between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) suppliers

- Pose a clear request for details on what you want

- Order samples first to avoid ordering larger amounts

Directories and Platforms Specific to Industry

Specialist jewelry manufacturing directories can also provide vetted suppliers:

- Many industry associations have lists of good manufacturers

- There are also platforms that help connect general consumers with specialized manufacturers — and by “specialized,” we mean manufacturers who focus exclusively on jewelry production

- Membership to these directories usually signals a high level of professionalism

Social Media

Most modern custom earring manufacturers have a robust social media presence:

- Look for relevant hashtags such as #jewelrymanufacturing or #customearrings on Instagram and LinkedIn

- This is the jewelry industry, on Facebook and LinkedIn

- Check out potential manufacturers by looking at their portfolio, how they interact with clients, and how often they post

Company Websites

Much can be determined about a manufacturer’s capabilities from a manufacturer’s website:

- Search for in-depth information regarding their manufacturing processes

- Look for people who have portfolio similar to what you want to create

- Check certifications, how many years you have been in business, and clients testimonials

- Evaluate if they articulate their production capabilities and specialty services

Trade Shows and Exhibitions

In this digital age, face-to-face connection remains priceless:

- Research local or international trade shows specifically for jewelry

- Don’t go without queries and prerequisites.

- Talk to manufacturers about design ideas or samples

- If travel is impossible, explore virtual trade show options

Referrals and Networking

The best manufacturing pairing often comes from personal recommendations:

- Get other people in the jewelry industry to ask about their manufacturing experiences

- Then join it with industry associations and networking events

- Join online communities around jewelry design and production

Selecting the Right Manufacturer: Criteria to Consider

Experience and Expertise

- When assessing a custom earring manufacturer, don’t just look for general jewelry experience:

- How long have they been making earrings as such?

- Are they familiar with the materials you want to use and the complexity of your design?

- Inquire about similar projects they’ve done and challenges they’ve faced

- Ask for examples of their work that parallel your vision

Reputation and Reliability

Reputation: A history of success from the manufacturer goes a long way:

- Study reviews: check on several different sites

- Ask for and call references from current or former clients

- Evaluate their responsiveness during initial inquiries

- Check for clarity about what they do and don’t do

Product Quality

Sample Evaluation Perhaps the most crucial step is:

- If you are going to start production, always ask for samples first

- Test samples for material quality, finishing details, and durability

- Familiarize yourself with their quality control method at every production stage

- Inquire into their defect rate and what they do when there is a quality problem

Customization Options from Earring Manufacturers

A good custom earring manufacturer will be flexible:

- Material-Specific Expertise: Prove experience with your materials

- Design Complexity Capabilities: Check if they can process the complexity of your design.

- Modification Flexibility: Understand their openness to modifications during the development phase

- All Packaging and Branding Options: Confirm they can customize with your branding elements

Manufacturing Capabilities

To do so you should know their technical capabilities:

- Manufacturing capacity and what it means for the quantity you need

- Technology and Equipment (CAD/CAM capabilities, 3D printing, etc.)

- Scale production capabilities as your business expands

- Specific Methods Relating to Your Design

Minimum Order Quantity (MOQ)

That is a significant consideration for smaller businesses, especially MOQs:

- Know their regular MOQ demands

- Consider constraints on quantity of initial orders

- Talk about graduated ordering options as your business expands

- If needed, consider manufacturing professionals who specialize in small-batch production

Website & Contact Options

The digital surface of a manufacturer provides hidden insights:

- Well- Structures website with presentation and most important information

- Engaging social media presence

- Training data is updated until October 2023

- Multiple channels (E-mail, phone, message, etc.)

Location and Logistics

Geographic considerations affect both cost and convenience:

- Consider the time zone differences and how they impact the ability to communicate

- Know about shipping fees, customs requirements and delivery times

- Compare the advantages of local vs. global manufacturing

- Assess the effect of geographical location on production costs and quality assurance

More Business Benefits

Some producers provide value beyond production:

- Design support and technical advice

- Pool trends and insights Thanks for subscribing!

- Refined manufacturing practices (sustainable and ethical production)

- Links to other services (packagers, shippers, etc.)

Certifications and Compliance

Confirm that the manufacturers are industry compliant:

- Check for related certificates in the jewelry industry

- Validate conformity with local standards (precious metals, in particular)

- Look for Fair Trade or other ethical sourcing certifications

- Ensure compliance to labor and environmental laws

How to First Contact and Reach Out

Preparing Your Inquiry

When reaching out to a custom earring manufacturer, first impressions are key:

- List out detailed product specs/technical requirements

- Include clear illustrations, sketches or 3D renderings Attach

- Indicate quantity needs and price target points

- Highlight specific certifications or compliance requirements

- Define your expectations around timeline

Correct way to choose the proper communication channel

Choose the method of contact that is most appropriate:

- Email for complex questions with files

- Phone calls for immediate questions or clarifications

- Application Initial Expression of Interest (IEOI) Online Forms

- Calls for complex discussions on designs.

Key Questions to Ask

This data should inform your first outreach and answer these key questions:

- Will they be able to create earrings using the specific materials and design specifications you have?

- What is their MOQ & pricing structure?

- What is their approximate sampling process, and what are the costs?

- What are their average production lead-time?

- How do they safeguard clients’ intellectual property?

Navigating Communication and the Design Process

Setting clear communication lines

Establish communication expectations from the start:

- Identify preferred methods and frequency of communication

- Identify contacts on both sides

- Set a schedule for updates and communication

- Keep an accurate written record of everything discussed and decided

Design Input and Collaboration:

Collaborationin effective design is crucial when working with a custom earring manufacturer:

- Offer specific art and design guidelines (file types, sizes)

- Be aware of the manufacturers design abilities and restrictions

- If available from the manufacturer, use design templates

- Accept technical feedback that can significantly change your design

Protection of Intellectual Property

Protecting your designs should be a priority.

- Always use NDAs (Non-Disclosure Agreements) when sharing designs

- Talk to your potential manufacturers about IP protection pieces

- Know your legal rights in the country of manufacture

- Trademark or design patent protection for signature pieces

A High-Level Guide in Three Steps

This sampling process requires attention to detail in order to realise your vision:

- Know what exactly happens at every stage of sampling

- Check for materials and craftsmanship at all levels, as well as design accuracy

- When adjustments are needed, give them clear, specific feedback

- Keen for the approval of the final sample before moving on to full production

Branding and Customization

Make your products uniquely yours:

- Negotiate ways to add logos or other brand elements

- Discover the custom packaging options

- Think about special finishes or signature touches

- Stay true to your overall brand identity

How to Understand the Manufacturer’s Quality Control Processes

Quality assurance must be a systematised process:

Get to know QC processes: Every step of production

- Inquire about any technologies that are used to verify quality

- Learn how raw materials for the products you use are sourced and checked

- Ask for documentation of quality control procedures

The Importance of Inspections

Pre-shipment verification safeguards your investment:

- Before shipping, discuss options to inspect the shipment

- Use third-party inspection services for big orders

- Develop a list of key quality assurance criteria to check

- Protocols for defects or quality issues

Warranty and Return Policies

Policies in place prevent future disputes:

- Familiarize yourself with the terms of the manufacturer’s warranty

- Set up protocols for returns or replacements

- Capture all quality metrics and remediation activities

- Explain how quality issues, if identified post-delivery, will be addressed

Multichannel: Sales Support and Communication

The relationship goes further than production:

- Consider the manufacturer’s responsiveness to questions after production

- Outline continued support for reorders or changes

- Whatever you decide to implement, create feedback channels to improve it

- Think about the way they deal with customer complaints or product problems

Logistics and Shipping

Delivery closes the loop in the manufacturing process:

- Evaluate shipping options and fees

- Track capabilities and transit times

- Talk about insurance coverage while the shipping process

- Customs clearance and import requirements

Fostering a Long-Term Relationship

Setting Up Clear Communication Protocols

Structured communication is necessary for long-term success:

- Routine check-ins and performance reviews

- Distinct contacts for various needs

- Processes for orders, alterations and issues documented

- The isotopes with the title Accurate feedback Mechanisms

Evaluating Potential for Growth and Scalability

When evaluating an earring supplier or custom earring manufacturer, look beyond general jewelry experience:

- Talk to them about their ability to manage larger order volumes

- Learn about their plans to upgrade any equipment or technology

- The concept of having the ability to expand their offerings

- Do their financials and business everlastings matter

Impressions about Shared Values and Ethical Practices

Partnerships are strengthened with alignment on principles:

- Talk about ethical sourcing and production practices

- Learn about common pledges on sustainability

- Do you see eye to eye on business values and practices

- Assess social responsibility programs

Performance Evaluations and Regular Feedback

Honest assessment is required for continuous improvement:

- Establish routine manufacturing performance reviews

- Deliver effective critique of products and processes

- Market reaction and customer feedback

- Work together with you on improvements and new ideas

Conflict Resolution: Strategies and Techniques

Even the strongest partnerships have their hiccups:

- Define the procedures to be followed for handling quality issues

- Establish transparency around escalation paths for severe issues

- Get Solutions, Not Blame

- Put in writing agreements on how disputes will be resolved

Advice for Startups and Small Businesses

From start small, strategic approach:

- Collaborate with manufacturers who embrace lesser clients

- Find no minimum order or low moqs manufacturers

- Raise the question of local craftspeople for initial production runs

- Find manufacturers who will grow with your business

- Negotiate better terms for smaller production runs

Learn More About Regional Differences in Manufacturing

Manufacturing in China

For the world’s biggest jewelry making hub, China remains the world’s largest hub for earring manufacturers and wholesale earring suppliers, offering:

- Price competition on all levels of quality

- A world-class manufacturing ecosystem

- Various types of material and production methods

- Potential communication and production-related concerns

Manufacturing in India

India’s jewelry tradition makes it an excellent source for earring suppliers specializing in:

- Solid workman skills especially for the elaborate designs

- And skilled artisans with competitive labor costs

- Craned and hand set expertise in gemstones and traditional methods

- Technological capabilities have been increasing

Manufacturing in the USA/Europe

The distinct advantages of domestic manufacturing are:

- Facilitated communication and quality assurance

- Longer lead times and shipping distance

- “Made in USA/Europe” marketing value

- Tougher intellectual property protections

- Increased costs of production and labor

Other Regions

Think specialized manufacturing hubs:

- Italy: World famous for luxury craftsmanship and design

- Thailand: Well known for silver jewelry and gemstone setting

- Turkey: Renowned for gold jewelry and competitive prices

- Vietnam: The new quality alternative to China

Cost Control and Budgeting

Managing manufacturing costs is a strategic matter:

- Design for efficient manufacturing

- Ask manufacturers for detailed breakdowns of costs

- Obtain Quotes From Multiple Suppliers

- Be aware of how material selections affect pricing

- Think about the total cost – shipping, duties, quality control.

- Request for repeat orders and volume discounts

Conclusion

Researching the best custom earring manufacturer takes due diligence, clear expectations, and several rounds of testing. So the key is understanding your needs, knowing all available routes and making an objective choice around potential partners; that way you can create a manufacturing partnership that will translate your original designs to product with the right income that your customers expect.

Keep in mind that the best manufacturing partnerships are built on mutual respect, clear expectations, and ongoing communication. So make sure to take your time because the right manufacturer will be a true partner for the growth of your jewelry business for many years down the line.

Your Journey to find your perfect custom earring manufacturer starts here, whether you are looking to launching a new jewelry line or expand your existing collection, knowing exactly what you need and searching well will get you where you want to be. There is always a perfect manufacturing partner at the end of the search.

Custom Earring Manufacturers FAQs

What is the general MOQs for custom earrings?

MOQs differ greatly from manufacturer to manufacturer and by material. MOQs for precious metals could be in the range of 10-20 pieces per design and for fashion jewelry, 50-100 pieces. Manufacturers usually specialize in one or the other: Some produce small batches with no minimum orders, others produce production runs of 500 pieces or more.

What is the usual timeline for the custom earring process?

The timeline depends on the design complexity, materials used and quantity. For example, a simple design could take 2-4 weeks once approved to complete production, whereas a more complex design with many parts could take 6-8 weeks or longer. Be sure to factor in additional time for shipping, customs clearance, and possible amendments.

So, how do I stop manufacturers from copying my earring designs?

Never share designs without NDAs (non-disclosure agreements) in place. Partner with manufacturers that take IP protection seriously. Apply for design patents or trademarks for signature pieces. Develop relationships with manufacturers who have a good name and care about their reputation and client relationships.

The Difference Between OEM and ODM Earring Manufacturers

OEM: Original Equipment Manufacturer (OEM) — manufacturing to their specifications and designs ODM: You can buy existing design which can be modified or branded. OEM generally works well for specific designs, while ODM can suit the case of standard styles since this will be quicker and more affordable.

How to assess the quality of a custom earring manufacturer?

Request samples of past work similar to your designs. How hot are their current references? Check for certifications and adherence to industry standards. Ascertain responsiveness and transparency in communications. Make an initial order in smaller quantities to test quality before committing to larger production runs.

What to include in your first inquiry to a custom earring maker

Provide clear design specifications, material requirements, estimated quantities, target price points, timeline expectations, and any specific quality standards or certifications you require. The more specific your questions are, the more precise the types of responses that the manufacturer will give.

Is it better to work with local or overseas custom earring manufacturers?

It’d depend on your priorities, though. Local manufacturers usually mean better communication, less shipping time and less complicated logistics — but pricier. Foreign manufacturers usually offer lower prices and specialized expertise but involve more complex logistics and communication. Think about what is important for your business model.

What’s the difference between an earring manufacturer and an earring supplier?

An earring manufacturer focuses primarily on the production process, creating earrings from raw materials according to specifications. An earring supplier may manufacture products but also serves as a distribution intermediary, often offering ready-made designs, packaging solutions, and sometimes handling logistics. Wholesale earring suppliers typically specialize in bulk orders for retailers and may offer both custom and stock designs.

Related Posts

The Ultimate Guide to Finding Your Custom Earring Manufacturer

Sick of gaudy jewelry drowning the market? You have unique methods to create earring designs that you wish to make a reality today but don’t