Custom Engraved Jewelry Wholesale: Adding a Personal Touch

In today’s competitive retail market, standing out is everything. Consumers are no longer just buying products; they are seeking experiences and connections. For jewelry brands and retailers, this shift presents a golden opportunity. The demand for personalized items is surging, with studies showing that 86% of Americans value jewelry with emotional significance over a high price tag. This is where custom engraved jewelry becomes a game-changer for your business.

Offering pieces that tell a story—a name, a special date, a meaningful quote—transforms a simple accessory into a cherished keepsake. As a wholesale buyer, incorporating custom engraved jewelry into your collection isn’t just about adding a new product line; it’s about unlocking higher profit margins, building profound customer loyalty, and creating a brand that resonates on a personal level. This guide will walk you through everything you need to know to successfully source and sell custom engraved jewelry at a wholesale level.

Why Custom Engraved Jewelry is a 7-Figure Opportunity for Your Business

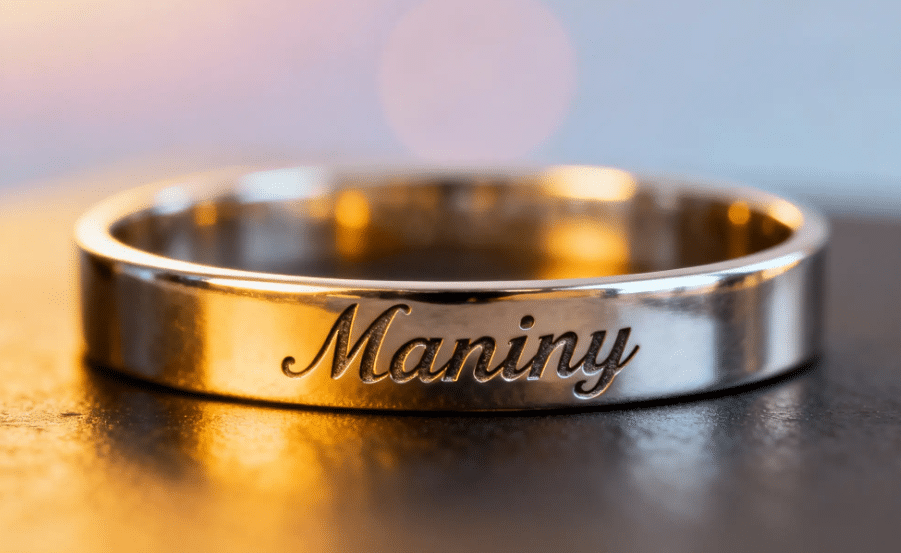

The logic is simple: personalization increases perceived value. A plain stainless steel necklace might compete on price, but a necklace engraved with a child’s name or the coordinates of a special place competes on emotion. This emotional connection allows you to command premium prices and build a loyal customer base that returns for every major life event.

- Higher Profit Margins: Engraving turns a commodity blank, which might cost a few dollars, into a personalized gift that can retail for $30, $60, or even more. The added value far exceeds the minimal cost of the engraving process itself.

- Increased Customer Loyalty: When a customer buys a personalized piece, they are investing in a memory. Your brand becomes part of their story, fostering a connection that mass-produced items can’t replicate. This leads to repeat business for birthdays, anniversaries, and holidays.

- Unlimited Design Potential: Unlike traditional manufacturing that requires molds or dies, engraving allows for infinite variations with zero tooling costs. You can offer hundreds of font, icon, and layout combinations, catering to a wide range of tastes without holding excess inventory.

- Perfect for E-commerce: Personalized products are a natural fit for online platforms like Shopify, Etsy, and social media. They generate user-generated content, glowing reviews, and powerful word-of-mouth marketing.

Personalized necklaces are a top-seller in the custom engraved jewelry market.

Understanding Engraving Technologies: What Wholesale Buyers Must Know

When sourcing custom engraved jewelry, understanding the technology behind the personalization is crucial. The method used affects the final look, durability, production speed, and cost. For wholesale, efficiency and consistency are paramount.

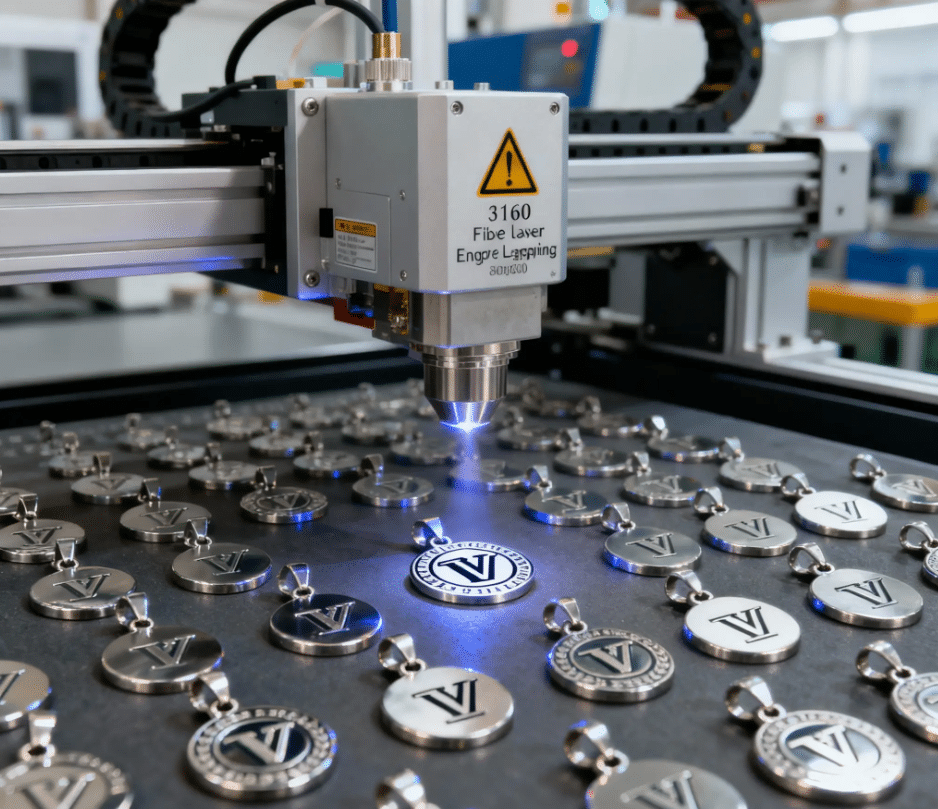

Laser Engraving: The Modern Standard for Precision and Scale

Laser engraving is a non-contact process that uses a focused beam of light to vaporize or alter the surface of the material. It’s the dominant technology for modern jewelry customization due to its speed, precision, and versatility.

- Fiber Lasers: This is the gold standard for engraving metals. Operating at a wavelength around 1064nm, fiber lasers are highly absorbed by materials like stainless steel, titanium, gold, and silver. They create crisp, permanent marks with exceptional detail. Advanced MOPA fiber lasers even allow for controlled color marking on certain metals like stainless steel and titanium by creating precise oxide layers.

- CO₂ and Diode Lasers: These lasers have different wavelengths and are typically used for organic materials like wood, leather, and acrylic. They can mark metal only if it has a coating (like anodized aluminum) or if a special marking spray is applied beforehand. For a business focused on metal jewelry, a fiber laser is the superior investment.

Mechanical Engraving: The Traditional Touch

This method uses a physical tool, typically a diamond-tipped bit, to carve into the metal. It’s a contact process that removes material to create the design.

- Diamond-Drag: A non-rotating diamond tip is dragged across the surface, creating fine, sharp lines. It offers a classic, handcrafted look.

- Rotary Engraving: A spinning cutter carves out the material, allowing for deeper and wider cuts.

While mechanical engraving produces a beautiful, tactile “V-cut” that reflects light brilliantly, it is generally slower and less versatile for intricate graphics compared to lasers. The physical contact also poses a slight risk to delicate pieces, and tool wear is a factor in high-volume production.

Hand Engraving: The Artisanal Choice

The oldest and most artistic method, hand engraving involves a skilled artisan using handheld tools called gravers to carve designs directly into the metal. Each piece is a unique work of art. While it offers unparalleled character, it is not scalable for most wholesale custom engraved jewelry operations due to its time-intensive nature and high cost. Fiber lasers offer unmatched speed and precision for wholesale custom engraved jewelry production.

Choosing the Right Materials for Wholesale Custom Engraved Jewelry

Your choice of material directly impacts engraving quality, durability, and price point. As a wholesale manufacturer, we at HonHo Jewelry prioritize materials that offer a balance of beauty, performance, and value.

Stainless Steel (316L): The Durable and Hypoallergenic Workhorse

This is the ideal starting point for any brand. 316L surgical-grade stainless steel is affordable, incredibly durable, and hypoallergenic. It doesn’t tarnish or rust, making it perfect for everyday wear. It engraves beautifully with a fiber laser, producing a sharp, dark mark. For enhanced durability and color options like gold or rose gold, we utilize an in-house PVD (Physical Vapor Deposition) plating process, which creates a finish far more resilient than traditional plating.

Sterling Silver (925): Classic and Timeless

A classic choice for its bright luster and premium feel. Silver is softer than steel, so it requires careful handling during engraving. The resulting mark is often more subtle and elegant. It’s an excellent option for higher-end personalized gifts.

Brass and Copper: For Fashion-Forward Collections

These metals offer a warm, vintage appeal. They are easy to engrave and can be plated to achieve various looks. However, they can tarnish over time and may require a protective coating to maintain their finish, which is an important consideration for customer satisfaction.

Titanium: Modern, Lightweight, and Strong

Titanium is as strong as steel but 45% lighter. Its modern, grayish tone and hypoallergenic properties make it popular for men’s jewelry and minimalist designs. It produces a high-contrast mark when engraved with a fiber laser.

A Note on Plated Jewelry: Risks and Rewards

While cost-effective, standard plated jewelry can be risky for engraving. If the laser settings are incorrect, the laser can burn through the thin plating, exposing the base metal underneath and leading to discoloration or peeling. This is why a reliable manufacturer with advanced plating technology like PVD is essential. It ensures the engraved piece remains beautiful for years to come.

The 7-Step Custom Jewelry Manufacturing Process: From Concept to Collection

Transforming an idea into a market-ready collection involves a precise and collaborative workflow. As an experienced jewelry manufacturer, we’ve refined this process to ensure quality and efficiency at every stage.

- Consultation & Design Brief: It all starts with your vision. You provide sketches, inspiration images, or just a concept. We discuss target audience, budget, and material preferences to create a clear project scope.

- CAD/3D Modeling: Our designers use specialized software to create a detailed 3D model of your piece. This digital blueprint allows you to review the design from every angle and make precise adjustments before any physical material is used.

- Prototyping: Once the CAD model is approved, we create a physical prototype, often using 3D printing to create a wax or resin model. This allows you to feel the piece’s size and proportions, ensuring it’s perfect.

- Casting and Mold Making: The prototype is used to create a master mold. Molten metal is then poured into the mold to cast the jewelry blanks. This process ensures consistency across your entire bulk order.

- The Engraving Process (Bulk Production): This is where the magic happens. Using our advanced fiber lasers and custom-made jigs to hold each piece securely, we engrave your designs with speed and perfect repeatability. Our workflow is optimized for batch processing, ensuring every piece is identical.

- Finishing, Plating, and Quality Control: After engraving, each piece is polished to a brilliant shine. If required, they undergo our in-house PVD plating for a durable, long-lasting color. Every single item is then inspected to meet our stringent quality standards.

- Packaging and Global Shipping: Finally, your custom jewelry is packaged according to your branding requirements—from simple pouches to custom gift boxes—and shipped efficiently to your location anywhere in the world.

CAD modeling is a crucial step for visualizing and perfecting your custom engraved jewelry design before production.

Key Laser Parameters for Perfect Engraving Results

Achieving a perfect engraving isn’t just about having a good machine; it’s about mastering the settings. While your manufacturer will handle this, understanding the key parameters helps you communicate your desired outcome. This technical insight is what separates amateur results from professional, high-quality products.

- Power (%): Controls the intensity of the laser beam. Higher power creates deeper, darker marks. For deep engraving on stainless steel, settings often start at 80-100%.

- Speed (mm/s): Determines how quickly the laser head moves. Slower speeds allow more energy to be delivered to one spot, resulting in a deeper mark. A typical speed for deep engraving might be 800-1500 mm/s, while faster speeds are used for light surface marking.

- Frequency (kHz): This is the number of laser pulses per second. Lower frequencies (e.g., 20-50 kHz) deliver higher energy per pulse, ideal for deep engraving. Higher frequencies (e.g., 60-100 kHz) produce finer, smoother marks, perfect for annealing or polishing.

- Hatching: This refers to the fill pattern used to engrave an area. A cross-hatch pattern (engraving at 0 degrees, then again at 90 degrees) creates a more uniform and darker fill. The line spacing within the hatch determines the overlap and final texture.

A common recipe for deep, dark engraving on stainless steel with a 30W+ fiber laser might be: 90% Power, 1000 mm/s Speed, 30 kHz Frequency, with a 0.05mm cross-hatch pattern. Adjusting these variables allows for a wide range of effects.

Finding the Right Wholesale Partner for Custom Engraved Jewelry

Your choice of a manufacturing partner is the single most important decision you’ll make. A great partner is more than just a supplier; they are an extension of your team.

Look for a manufacturer who offers:

- In-House Capabilities: A partner with in-house design, casting, engraving, and plating (especially PVD) like HonHo Jewelry has full control over quality and lead times. This eliminates the delays and inconsistencies that come from outsourcing to multiple vendors.

- Material Expertise: They should be able to advise you on the best materials for your designs and budget, explaining the pros and cons of each.

- Flexible MOQs: A good partner understands the need to test the market. Look for flexible Minimum Order Quantities that allow you to launch new designs without massive upfront investment.

- Transparent Communication: From initial quote to final delivery, you should receive clear, prompt communication. They should provide spec-based quotes that detail material, weight, and plating thickness so you can compare apples to apples.

- Proven Quality Control: Ask about their QC process. Do they inspect every piece? What is their defect rate? A reliable partner will have stringent checks at every stage of production.

Rigorous quality control is essential for delivering consistently beautiful custom engraved jewelry.

Common Engraving Issues and How to Avoid Them in Bulk Orders

When ordering custom engraved jewelry in bulk, consistency is key. Here are common issues and how a professional manufacturer prevents them:

- Misaligned Engraving: This happens when the jewelry piece is not held securely. We use custom-made jigs and fixtures that hold each item in the exact same position, ensuring perfect alignment across thousands of units.

- Uneven Depth or Faint Marks: This is often due to incorrect focus or inconsistent power output. Professional-grade lasers have stable power sources, and we calibrate focus for every batch to guarantee a consistent, deep mark.

- Discoloration or “;Halos”: A brownish or burnt look around the engraving is caused by excessive heat. This is controlled by fine-tuning the laser’s speed and frequency settings to achieve a clean mark without damaging the surrounding area.

- Damage to Plated Surfaces: As mentioned, engraving can compromise poor-quality plating. By using robust PVD coating and precisely controlling the laser depth, we ensure the engraving is permanent without damaging the finish.

Ready to Elevate Your Brand with Custom Engraved Jewelry?

Stop competing on price and start connecting with your customers on a deeper level. HonHo Jewelry is your trusted partner for high-quality, wholesale custom engraved jewelry. With over 15 years of experience and our own in-house PVD plating factory, we deliver superior products with flexible MOQs and factory-direct pricing.

Let’s bring your vision to life. Share your design ideas with our expert team today.Get Your Free Quote Now

Frequently Asked Questions (FAQ)

What is the best type of laser for engraving metal jewelry?

A fiber laser is the best choice for engraving metal jewelry, including stainless steel, gold, silver, and titanium. Its wavelength is highly effective at creating permanent, high-contrast marks with excellent precision.

What is the minimum order quantity (MOQ) for wholesale custom engraved jewelry?

At HonHo Jewelry, we offer flexible MOQ options, starting as low as 30 pieces per style. This allows emerging brands to test new designs and manage inventory risk effectively.

How long does the custom manufacturing process take?

The typical timeline from final design approval to delivery is 25-35 days. This includes sampling (7-20 days) and bulk production. We also offer efficient global shipping to ensure timely delivery.

Can you engrave on plated jewelry?

Yes, but the quality of the plating is critical. We use an advanced PVD (Physical Vapor Deposition) plating process that creates a highly durable finish, allowing for clean engraving without the risk of peeling or discoloration common with standard plating.

What file format do I need for my custom design?

You can provide your design as a sketch, photo, or digital file (like .AI, .SVG, .DXF, or .JPG). Our design team can work with your concept to create a professional CAD model for production.

Can you engrave photos or complex logos on jewelry?

Yes, laser engraving technology allows for highly detailed and complex designs, including photos and intricate logos. The quality of the final result depends on the resolution of the source image and the surface area of the jewelry piece.

What is the difference between laser engraving and laser etching?

Laser engraving vaporizes material to create a mark with physical depth. Laser etching melts the surface to change its texture and color, creating a raised mark with very little depth. Both are permanent, but engraving is generally more durable.

How do you ensure consistency in large wholesale orders?

We use a combination of precise CAD/CAM technology, custom jigs for holding each piece, calibrated laser settings, and a multi-stage quality control process to ensure every piece in a bulk order is identical to the approved sample.

share this recipe:

Still hungry? Here’s more

Choosing the Right Jewelry Clasp for Custom Designs

Introduction When designing custom jewelry, the clasp is often the unsung hero – it’s the

How to Dodge Jewelry Sourcing Risks from China: Your 2026 Playbook

The allure of jewelry sourcing from China is undeniable. It’s a global hub of manufacturing,

Top 50 Jewelry Brands Worth to Buy 2026: The Definitive Investment & Style Encyclopedia

The global jewelry market in 2026 is a fascinating landscape where centuries-old heritage meets cutting-edge

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.