Choosing the Best Jewelry Stone Setting for Mass Production

Selecting the right jewelry stone setting is one of the most pivotal decisions for any jewelry brand. It goes far beyond simple aesthetics. For businesses focused on mass production, this choice directly impacts your bottom line, production speed, product quality, and brand reputation. A setting that looks beautiful on a single custom piece might become a nightmare of costs and delays when you need to produce thousands.

Understanding the nuances of each setting from a manufacturing perspective is the key to scaling successfully. It’s about balancing beauty with efficiency, and durability with cost. This guide is designed for jewelry brands, designers, and entrepreneurs who need to make smart, scalable decisions. We’ll pull back the curtain on the manufacturing process to show you how to choose the best jewelry stone setting for your mass production needs, ensuring your designs are not only stunning but also profitable and consistently high-quality.

Why Stone Setting Choices are Critical for Mass Production

In custom, one-off jewelry, time and labor are part of the value. In mass production, they are costs to be managed. The jewelry stone setting technique you choose is a primary driver of these costs and can make or break your production workflow. Here’s why it’s so critical:

- Production Speed: Some settings, like simple prongs on calibrated stones, can be done relatively quickly. Others, like intricate pavé or bezel settings, are far more time-consuming, creating potential bottlenecks in your production line.

- Cost Per Unit: Labor is a significant portion of a jewelry piece’s cost. A setting that requires hours of a skilled artisan’s time will have a much higher unit cost than one that can be automated or completed quickly.

- Labor Requirements & Scalability: Complex hand-setting techniques require highly skilled jewelers, who are a finite resource. Relying solely on these methods can limit how quickly you can scale production. Simpler or automated setting processes are easier to scale up to meet large orders.

- Durability &; Return Rates: A poorly executed or unsuitable setting for mass production can lead to loose stones. This results in customer complaints, returns, and damage to your brand’s reputation for quality. A secure setting is non-negotiable.

A Manufacturer’s Look at Traditional Jewelry Stone Setting Methods

Before diving into advanced techniques, it’s essential to understand the foundational methods. While many guides explain these from a consumer’s viewpoint, a manufacturer sees them through a lens of efficiency, security, and cost. Here’s a breakdown of the most common types of jewelry stone setting.

| Setting Type | Description | Pros for Mass Production | Cons for Mass Production |

|---|---|---|---|

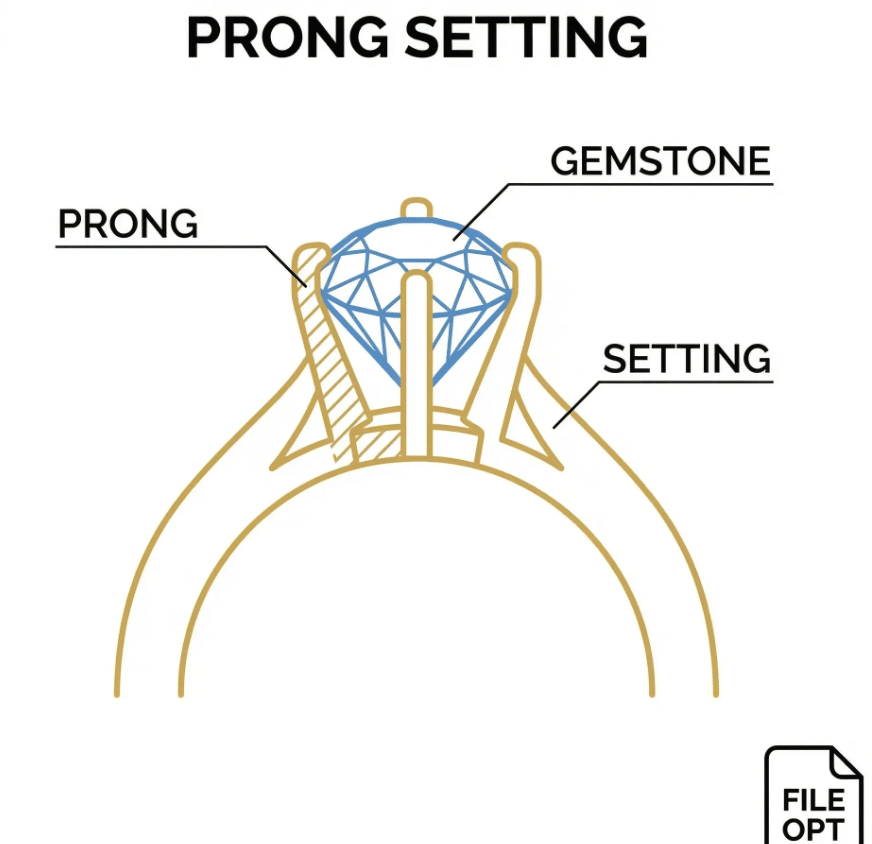

| Prong Setting | Small metal claws hold the gemstone in place, maximizing light exposure. | Fast to cast; uses less metal; excellent for showcasing stones. | Can be labor-intensive to set by hand; prongs can snag if not finished perfectly. |

| Bezel Setting | A metal rim fully or partially encircles the stone, offering maximum protection. | Extremely secure and durable; modern, clean look; protects stone edges. | Labor-intensive; requires more metal; can hide some of the stone’s size. |

| Channel Setting | Stones are set in a row between two parallel walls of metal with no metal between them. | Very secure and snag-free; creates a clean, continuous line of stones. | Requires precisely calibrated stones and channels; less forgiving of variations. |

| Pavé Setting | Small stones are set closely together, held by tiny beads of metal, creating a “paved” surface. | Creates a high-impact, brilliant look; can make smaller stones appear larger. | Traditionally very labor-intensive and requires high skill; can be difficult to repair. |

Deep Dive: Comparing Settings for Production Efficiency

When producing hundreds or thousands of pieces, small differences in efficiency add up. Let’s analyze these traditional settings specifically for scalability.

Prong Setting: The Versatile Workhorse

Prong settings are popular for a reason. The “heads” or “baskets” that hold the stones can be cast as part of the main piece, reducing assembly time. For mass production using calibrated (uniformly sized) stones, a skilled setter can secure stones relatively quickly. However, the process is still manual. The efficiency of prong setting depends heavily on the consistency of the castings and the stones. It offers a good balance of speed and beauty, making it a reliable choice for many designs.

Bezel Setting: The Security Specialist

From a production standpoint, bezel setting is one of the most secure but also one of the slowest manual methods. Each bezel must be perfectly shaped to the stone, and the metal must be carefully pushed over the edge without damaging the gem. This requires significant skill and time, driving up the cost per unit. It’s best reserved for designs where durability is the absolute top priority or for premium lines where higher labor costs are acceptable.

Channel & Bar Setting: The Kings of Consistency

Channel setting is built for efficiency in linear designs like eternity bands and bracelets. When the channel is cast perfectly and the stones are calibrated, a setter can place stones in a sequence and secure them efficiently. The bar setting, a variation where stones are held between vertical bars, operates on a similar principle. The key to making this method cost-effective is investing in high-precision custom jewelry manufacturing to ensure the castings are flawless, minimizing the need for manual adjustments.

The Game Changer: Wax Setting for High-Volume Production

This is where modern manufacturing truly separates itself from traditional jewelry making. For brands needing to produce thousands of stone-set pieces efficiently, the most important technique to understand is **wax setting**, also known as “cast-in-place” setting.

Instead of setting stones into a finished metal piece, wax setting involves placing the gemstones directly into the wax model *before* the casting process. The wax model, with the stones embedded, is then put into a flask, and investment (a plaster-like material) is poured around it. In the kiln, the wax melts away, leaving the stones perfectly suspended within the investment mold. Molten metal is then poured in, flowing around the stones and securing them as it cools.

The benefits for mass production are enormous:

- Massive Speed Increase: The entire manual stone-setting step is eliminated for hundreds of pieces at once.

- Drastic Cost Reduction: It dramatically reduces the highly skilled labor needed per piece.

- Unmatched Consistency: Since the stones are placed in the original master model, their position is identical across every single piece.

This process is often powered by an **automatic jewelry stone setting machine**, which can place thousands of stones per hour into wax molds with incredible precision. This technology is the engine behind many of the world’s largest jewelry brands, enabling them to produce intricate, stone-heavy designs at an accessible price point.

Which Stones and Settings Work for Cast-in-Place?

The magic of wax setting comes with a few technical rules. The primary consideration is whether a gemstone can survive the extreme temperatures of the casting process. Molten gold, silver, or stainless steel is incredibly hot, and not all stones can take the heat.

Stones Suitable for Wax Setting:

- Diamonds: With a very high melting point, diamonds are the ideal candidates for casting in place.

- Hard Sapphires and Rubies: These corundum-family gems are also very durable and can generally withstand the casting process.

- Cubic Zirconia (CZ): As a lab-created stone, it’s designed to be tough and is widely used in cast-in-place production.

- Certain Lab-Grown Gemstones: Many GRS-certified gemstones created in a lab are engineered for durability, making them suitable.

Stones to Avoid with Wax Setting:

- Emeralds: They often have natural inclusions that can expand and shatter under high heat.

- Opals, Pearls, Turquoise: These are soft, porous, and will be destroyed by the heat.

- Most Semi-Precious Stones: Gems like amethyst, peridot, and garnet have lower heat tolerance and are best set by hand after casting.

The jewelry stone setting style must also be compatible. Flush, pavé, and certain channel styles are perfect for wax setting, as the metal can flow and shrink around the stones to hold them securely. Complex prong or tension settings are generally not suitable for this method.

Hand Setting vs. Machine Setting: Finding the Right Balance

The choice between hand setting and machine-automated wax setting isn’t about one being “better” than the other; it’s about using the right tool for the right job. A strategic manufacturing partner will help you decide which approach, or combination of approaches, is best for your product line.

When to Use Machine/Wax Setting:

- For high-volume orders of the same design.

- For designs featuring many small, uniform stones (e.g., pavé).

- When using castable stones like diamonds, sapphires, or CZ.

- When cost-per-unit and speed to market are top priorities.

When to Use Hand Setting:

- For delicate, heat-sensitive, or irregularly shaped gemstones.

- For premium or bespoke collections where the “hand-finished” quality is a selling point.

- For complex setting styles like tension settings or intricate prong work.

- When setting large, high-value center stones that require individual attention.

Many mass-produced pieces use a hybrid approach. For example, a ring might have its small pavé accent stones cast in place, while the larger, more delicate center stone is set by hand afterward. This optimizes for both efficiency and quality.

Key Factors When Choosing Your Jewelry Stone Setting

As a brand owner or designer, here is a simple checklist to guide your conversation with a manufacturer:

- Design Complexity: How intricate is your design? Does it feature uniform stones in a pattern, or a variety of shapes and sizes?

- Stone Type: What gems are you using? Are they durable enough for wax setting, or do they require the delicate touch of hand setting?

- Target Cost: What is your target retail price and required margin? This will help determine how much labor cost the piece can absorb.

- Production Volume: Are you launching a small test batch or placing an order for 10,000 units? The scale will heavily influence the ideal method.

- Brand Positioning: Is your brand known for accessible fashion or high-end luxury? The setting technique can reinforce your brand’s story.

Partnering with the Right Manufacturer for Your Jewelry Stone Setting Needs

Choosing the right jewelry stone setting is a collaborative process. Your manufacturing partner shouldn’t just take your design and make it; they should act as a consultant, advising you on the best way to achieve your vision at scale. A great partner, like HonHo Jewelry, brings deep expertise in design for manufacturability (DFM).

Look for a manufacturer who:

- Offers a Range of Techniques: They should be masters of both traditional hand setting and modern, automated wax setting.

- Invests in Technology: A factory with advanced CAD/CAM software, high-precision 3D printers, and automatic setting machines is equipped for quality at scale.

- Has Robust Quality Control: Ask about their process for checking stone security, prong finishing, and overall quality at every stage.

- Provides Expert Guidance: They should be able to look at your design and suggest modifications that will improve production efficiency and durability without sacrificing aesthetics. Our expert design and engraving services are integrated with our manufacturing knowledge from day one.

- Works with Quality Materials: Ensure they use high-quality metals like stainless steel, copper, or 925 silver and can source reliable, premium materials and gemstones.

From diverse plating options to the final bespoke packaging, every step is influenced by these initial design and setting decisions.

Ready to Scale Your Jewelry Production with the Right Stone Setting?

Choosing the perfect jewelry stone setting for mass production is complex, but you don’t have to do it alone. At HonHo Jewelry, we combine decades of craftsmanship with cutting-edge technology to deliver scalable, high-quality solutions for brands worldwide.

Let our experts help you optimize your designs for efficiency, cost, and durability. Contact us today to discuss your project and get a free consultation.Send Your Inquiry Now

Frequently Asked Questions

What is the most cost-effective jewelry stone setting for mass production?

For designs with many small, durable stones like diamonds or CZ, wax setting (cast-in-place) is by far the most cost-effective method due to automation and reduced labor. For simpler designs with single stones, a standard prong setting is often a good balance of cost and speed.

Can all gemstones be used in mass production?

Yes, but the setting method must match the stone’s durability. Hard stones like diamonds, sapphires, and lab-grown gems are versatile and suitable for efficient methods like wax setting. Softer or heat-sensitive stones like emeralds, opals, or pearls must be set by hand after casting, which is slower but necessary to prevent damage.

What is the difference between pavé and micro-pavé setting?

Both involve setting small stones close together. Micro-pavé is a more refined version that uses even smaller stones (often under 1mm) and requires a microscope for precision. It creates a more seamless, diamond-encrusted surface but is more labor-intensive if done by hand. Both are excellent candidates for wax setting in mass production.

How does a jewelry stone setting affect the final price of a product?

The setting has a major impact on price. Labor-intensive settings like hand-set bezels or intricate pavé work increase the cost per unit. Automated wax setting significantly reduces labor costs, making the final product more affordable. The amount of precious metal used in the setting also contributes to the cost.

What is the most secure type of jewelry stone setting?

The bezel setting is generally considered the most secure, as it fully encases the edge of the stone in metal. This makes it ideal for daily wear and for protecting softer gemstones. Channel settings are also very secure for rows of stones.

Why is stone calibration important for mass production?

Stone calibration means ensuring all gemstones in a batch are precisely the same size, shape, and cut. This is critical for mass production, especially for channel and pavé settings, as it allows the settings to be created uniformly. Inconsistent stone sizes would require manual adjustments for every single piece, defeating the purpose of efficient production.

Can you mix different setting types in one piece for mass production?

Absolutely. This is a common strategy called a hybrid approach. For example, a manufacturer might use efficient wax setting for small accent stones on a ring’s band and then have a skilled artisan hand-set a large, featured center stone. This optimizes for both cost and quality.

What is “Design for Manufacturability” (DFM) in jewelry?

Design for Manufacturability means designing a piece of jewelry with the production process in mind. An experienced manufacturer can advise on small design tweaks—like adjusting a prong’s thickness or the angle of a channel wall—that can make the piece much faster, cheaper, and more durable to produce at scale without compromising the original vision.

share this recipe:

Still hungry? Here’s more

The Unseen Hero: Why Earring Backings Define Quality Jewelry

Every jewelry brand owner knows the sinking feeling. A customer calls, distraught. They’ve lost one

Best Jewelry Stone Setting for Mass Production | HonHo

Choosing the best jewelry stone setting Choosing the best jewelry stone setting is one of

Custom Engraved Jewelry Wholesale: Adding a Personal Touch

In today’s competitive retail market, standing out is everything. Consumers are no longer just buying

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.