Top 13 Custom Earring Manufacturers in China 2026 Guide

Key Trends in China’s Custom Earring Manufacturing 2026

If you’re planning custom earring OEM in China for 2026, the landscape is shifting fast. I’ll keep this tight and practical so you can make clear sourcing decisions.

Sustainability and Recycled Metals

By 2026, sustainability is no longer a “nice-to-have” for Chinese earring factories—it’s a sales requirement:

- More recycled stainless steel, brass, and silver being used, especially for fashion and mid-range lines.

- Larger manufacturers are offering traceable recycled metals and nickel-free, lead-free alloys to hit US/EU compliance.

- Expect to see “eco lines” of hoops and studs marketed specifically for sustainable brands and marketplaces (Etsy, Amazon, Zalando, etc.).

If you want a future-proof line, I recommend locking in recycled metal specs and getting that written into your contract and QC checklist.

AI, CAD, and Tech-Driven Customization

Factories that used to only copy samples are now using AI and CAD to help brands create unique lines faster:

- AI-assisted moodboards and trend matching for 2026 jewelry trends (custom drops, helix, cartilage, and bridal).

- 3D CAD + rapid prototyping (resin/3D print) to cut sampling time from weeks to days.

- Easier custom logo engraving, initials, and personalized shapes with CNC and laser tech.

If you’re a small brand, you can now get ODM-style support that used to be reserved for big buyers—just be clear about your IP and get NDAs in place.

Material Choices and Cost Breakdowns

Most custom earring OEM quotes in China still revolve around four material tiers:

- Alloy + plating – lowest cost, ideal for high-volume fashion.

- Stainless steel (304/316L) – hypoallergenic, durable, mid-range price, great for wholesale stainless steel earrings manufacturers.

- Titanium – premium for sensitive-skin, piercing, and cartilage jewelry; higher cost but strong value for niche brands.

- Sterling silver / 14K–18K gold-plated – higher material cost, used for bridal, premium CZ, and small-batch luxury.

A simple rule I use with buyers:

- Material = 40–60% of cost,

- Labor + plating + stones = 30–40%,

- Packaging + compliance + overhead = 10–20%.

Choosing stainless instead of alloy, or titanium instead of stainless, can easily move your ex‑factory price 20–80% depending on design complexity and stone setting.

Market Forecasts Through 2026

Looking ahead to 2026, China’s custom earring manufacturing is set to grow in three clear segments:

- Fast-fashion & micro-trend earrings (low MOQ, rapid lead time earring OEM partners) driven by TikTok/IG styles.

- Hypoallergenic and nickel-free earrings for US/EU, especially studs, hoops, helix, and cartilage lines.

- Bridal, CZ, and personalized gift earrings (names, initials, birthstones) with higher margins and smaller volumes.

Most serious forecasts point to steady single- to low double-digit annual growth in custom earring OEM from China through 2026, with factories that combine sustainable materials + tech-enabled customization taking the lead.

If you align now with suppliers who are strong in recycled metals, CAD, hypoallergenic materials, and small-batch flexibility, you’ll be positioned correctly for where the market is going, not where it was.

How we picked the top 13 custom earring manufacturers in China 2026

When we shortlist custom earring OEMs in China, we treat it like we’re picking our own long‑term production partners. Every factory on this “Top 13” list passed a clear, practical set of filters that matter to global jewelry brands, Amazon sellers, and DTC startups.

1. Quality standards & certifications

We only considered factories that can prove consistent quality and basic compliance:

- Core certifications (at least one of these or equivalent):

- ISO 9001 (quality management)

- BSCI / SEDEX / SMETA (social & ethical audits)

- Third‑party audits from SGS, TÜV, Intertek, or similar

- Materials & safety:

- Ability to provide nickel-free, lead-free, and cadmium-free test reports

- Rohs/REACH or similar documentation on request

- Process control:

- Clear QC checkpoints: incoming material check, in‑process inspection, and final AQL‑based inspection

- Experience handling hypoallergenic jewelry (especially for stainless steel, titanium, and 925 silver)

For higher‑end producers, we also looked at experience with sterling silver, gold‑filled, and plated items; some of them share useful process details openly, similar to how we explain finishes on our own gold-filled vs. gold-plated jewelry guide.

2. Customization depth, OEM/ODM & design support

To make this list, a supplier had to be more than a basic wholesaler:

- OEM strength:

- Can manufacture from your drawings, samples, or 3D files

- Flexible metal options (stainless, titanium, brass, silver, etc.) and surface treatments

- ODM strength:

- In‑house design team or ready‑made trend decks

- Seasonal collections you can private label with small tweaks

- Tech & design tools:

- CAD design support, 3D rendering, and rapid prototyping

- Ability to revise samples fast and keep communication tight via email/WeChat

- Brand‑level support:

- Logo stamping, carding/packaging, barcode or FNSKU labeling

- Confidentiality for custom molds and brand IP

We favored factories that work the same way we do for custom design projects—from CAD to finished sample—like we describe on our own custom jewelry manufacturing page.

3. Capacity, pricing & MOQ fit

Our list is built for both early‑stage brands and scaling labels:

- Capacity:

- Stable monthly output with clear peak‑season planning

- Ability to ramp up from hundreds to tens of thousands of pairs without quality drop

- Pricing tiers:

- Transparent quotes that separate:

- Base metal cost

- Stone/setting cost (CZ, gemstones, pearls)

- Plating or PVD coating

- Packaging and add‑ons

- Transparent quotes that separate:

- MOQs:

- Options for low MOQ earring factories (50–200 pairs per style) for new launches

- Higher‑volume factories with sharp pricing for big box or marketplace sellers

- Lead times:

- Reasonable sample cycles (7–20 days for most designs)

- Mass production within a standard 25–40 day window outside peak season

We deliberately mixed suppliers so startups can test with smaller runs, while established brands can lock in serious capacity and better unit economics.

4. Client reviews, audits & data sources

We didn’t rely on catalog photos or sales pitches. Each manufacturer was checked using:

- Buyer feedback:

- Long‑term client reviews from platforms, B2B networks, and private brand references

- Evidence of repeat orders and multi‑year partnerships (not just one‑off trial runs)

- On‑site & remote audits:

- Factory visit reports (either our own or third‑party)

- Photos/videos of production lines, plating workshops, and packing areas

- Data & track record:

- Years in operation and export experience to North America, EU, UK, and Australia

- Dispute and claim history where visible (returns, quality complaints, late deliveries)

- Consistency of specifications vs. actual delivered goods

Only manufacturers that checked out from both the documentation side and the real‑world performance side made the final “Top 13 custom earring manufacturers in China 2026” list.

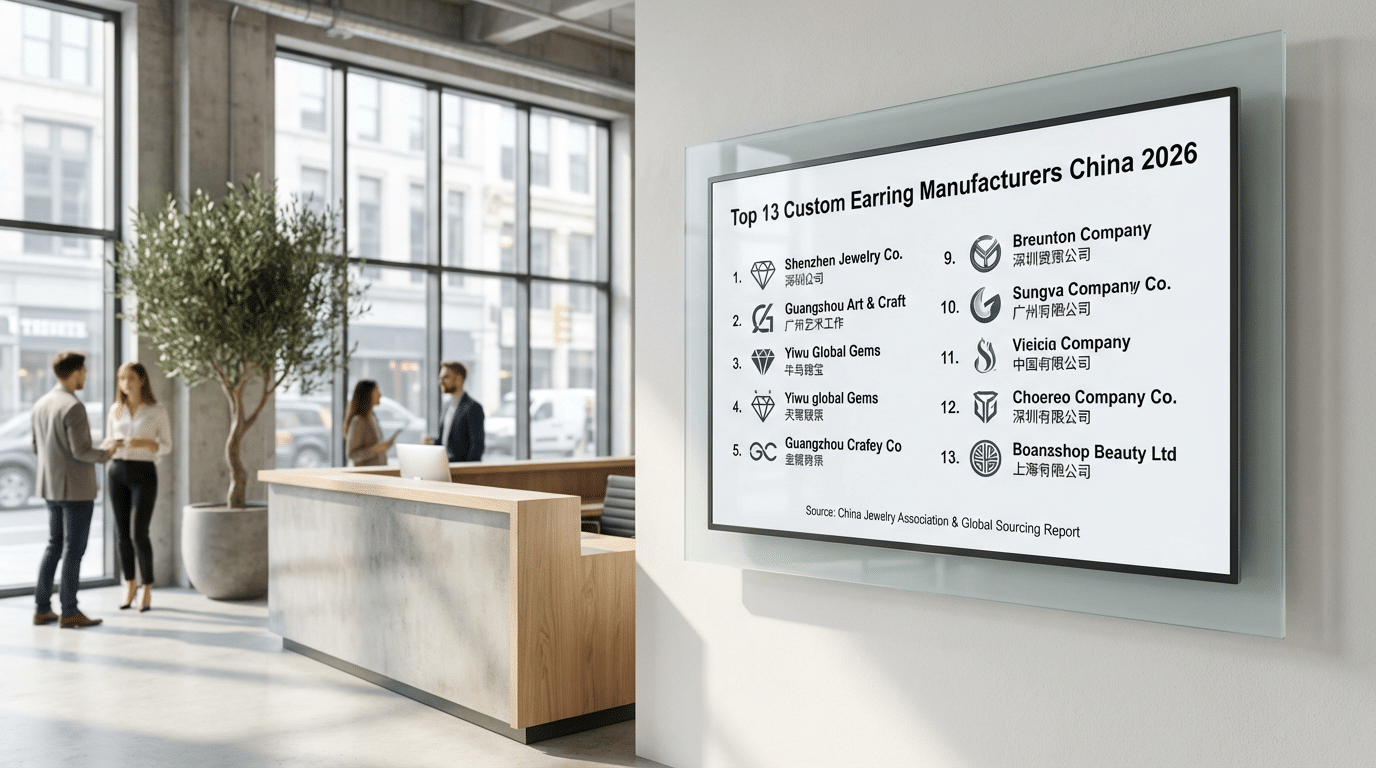

Top 13 custom earring manufacturers in China for 2026

If you’re planning custom earring collections for 2026, these are the China-based OEM/ODM partners I keep coming back to for reliability, flexibility, and price–value balance. Each one has a clear niche, so you can match them to your brand’s positioning and target markets.

1. Dongguan HonHo Jewelry – titanium & stainless custom earrings

For serious custom earring OEM in China, Dongguan HonHo Jewelry is my go-to. They’re strong on:

- Titanium and 316L stainless steel: great for hypoallergenic lines, piercing-safe hoops, and cartilage earrings.

- Gold vermeil and premium plating: if you need durable vermeil or PVD finishes, they already engineer for tarnish resistance and sweat/ocean wear. Their guide on what gold vermeil jewelry really is and how it compares to plating is worth reading before you lock in specs.

- Custom drops, huggies, and helix designs with full CAD support, small to mid MOQs, and stable quality across reorders.

If you want a partner that understands Western retail, packaging expectations, and long-term brand building, they’re one of the best wholesale stainless steel earring manufacturers to start with.

2. Yiwu Gemnel Jewelry – CZ & bridal earring specialists

Gemnel is strong for:

- High-sparkle cubic zirconia (CZ) bridal and evening earrings

- Matching wedding sets (earrings + necklace + bracelet)

- Low–medium MOQs for custom bridal lines and boutique brands

They’re particularly good if you sell on marketplaces (Amazon, Etsy) and need consistent, photo-ready stones and prong work.

3. TALMUD – personalized & themed earrings

TALMUD focuses on:

- Themed and souvenir-style earrings (travel, sport, culture, fan merch)

- Printed, enamel, and logo earrings for events, museums, and brands

- Agile for promotional projects and campaigns where design storytelling matters more than precious materials.

4. Nendine – sustainable custom hoops & studs OEM

Nendine’s niche is:

- Sustainable materials and recycled metals for hoops and studs

- Clean, minimal Scandi/Korean-inspired designs that global buyers look for

- Good for brands that need strong ESG messaging without insane price points.

5. Beyaly Jewelry – stainless steel & gold inlay earrings

Beyaly works well for:

- Stainless steel base + gold inlay or plated accents

- Engravable studs and huggies for personalization

- Strong OEM for DTC brands that want mid-tier pricing and long-lasting finishes.

6. Very Selection – trend-driven private label earrings

Very Selection is ideal if you chase TikTok / Instagram trends:

- Fast fashion and trend-driven private label earrings

- Quick sampling on ear cuffs, climbers, chunky hoops, and Y2K looks

- Better for volume and fast turnover than for ultra-premium builds.

7. Teemtry – cubic zirconia earrings with low MOQ

Teemtry is appealing for newer brands because of:

- Low MOQs on CZ earrings (studs, drops, halo designs)

- Wide color and cut options for CZ, easy to build seasonal mini-collections

- Great balance of cost and perceived value for giftable pieces.

8. Wuzhou Messi Gems – gemstone-focused premium earrings

If your line leans to fine or demi-fine, Wuzhou Messi Gems is strong on:

- Lab-grown and natural gemstones (sapphires, emeralds, spinels, etc.)

- Stone cutting, matching, and pairing for high-end stud or drop earrings

- Better used as a stone + setting partner when you want real-gem storytelling.

9. Guangxi Foxi Jewelry – bulk hypoallergenic earring supplier

Foxi is built for scale:

- Bulk orders of hypoallergenic earrings, especially stainless and alloy with nickel-free plating

- Mass market lines for supermarkets, chain stores, and subscription boxes

- Strong on simple studs, hoops, and sets under strict cost targets.

10. Fanny Jewelry – tungsten & carbide earrings OEM

Fanny Jewelry covers a niche that keeps growing:

- Tungsten and carbide earrings for men’s and unisex lines

- Dark, heavy, and ultra-durable styles for alternative, biker, and streetwear brands

- Great if you want to stand out from classic steel and brass offerings.

11. Azone Jewelry – alloy plating & mass fashion earrings

Azone is a typical Yiwu-style mass fashion earring manufacturer:

- Zinc alloy, brass, and mixed metal earrings with trend plating

- Statement drops, large hoops, tassels, and colorful fashion pieces

- Ideal when you need big variety at low cost for fast fashion collections.

12. DG Jewelry – cartilage & helix custom earring lines

DG Jewelry focuses on:

- Cartilage, helix, tragus, conch, and labret earrings

- Internally threaded and piercing-friendly designs

- Good if you’re building a body jewelry / piercing brand and need tight tolerances and clean finishing.

13. Paradise Jewelry – rhinestone & fashion earrings from Yiwu

Paradise Jewelry is a solid choice for:

- Rhinestone-heavy fashion earrings, party and occasion wear

- Bulk orders for costume jewelry and event-driven ranges

- Colorful, bold designs that work well for carnival, festivals, and themed drops.

Best manufacturers for startups vs. scaling brands

To keep it simple:

- Best for startups / small brands (low MOQs, good guidance)

- Dongguan HonHo Jewelry – structured support, higher quality base metals

- Teemtry – low MOQ CZ earrings

- Nendine – sustainable, minimalistic lines

- TALMUD – themed / niche collections with clear target buyers

- Best for scaling brands / big volume

- Guangxi Foxi Jewelry – mass hypoallergenic supply

- Azone Jewelry & Paradise Jewelry – fast fashion volume

- Yiwu Gemnel Jewelry – bridal and CZ sets at scale

If you’re building a long-term jewelry brand with custom designs across earrings, necklaces, and more, I’d start with a manufacturer that already understands Western retail and wholesale dynamics. Dongguan HonHo Jewelry, for example, shares broader insights on fashion jewelry wholesale for retailers that align closely with what most global buyers actually need in terms of margins and launch cycles:

https://www.honhojewelry.com/fashion-jewelry-wholesale-for-retailers/

Comparison table of the top 13 custom earring manufacturers in China 2026

I’ve put the key data for the top 13 custom earring OEMs in China into quick-scan tables so you can shortlist fast, whether you’re a new brand or already scaling.

Location & material expertise

| Manufacturer | City / Province | Core Materials / Expertise |

|---|---|---|

| Dongguan HonHo Jewelry | Dongguan, Guangdong | Titanium, stainless steel, 14K/18K gold-plated, nickel-free studs & hoops |

| Yiwu Gemnel Jewelry | Yiwu, Zhejiang | CZ, bridal earrings, wedding sets, silver-plated brass |

| TALMUD | Shenzhen, Guangdong | Themed, souvenir, enamel earrings, custom shapes |

| Nendine | Dongguan, Guangdong | Sustainable stainless, titanium, recycled metals, minimalist hoops/studs |

| Beyaly Jewelry | Shenzhen, Guangdong | Stainless steel, 925 silver, gold inlay, custom signet / statement pieces |

| Very Selection | Guangzhou, Guangdong | Trend-driven fashion alloys, private label collections |

| Teemtry | Yiwu, Zhejiang | Cubic zirconia fashion earrings, low-MOQ brass & alloy |

| Wuzhou Messi Gems | Wuzhou, Guangxi | Lab & natural gemstones, high-end stone-set earrings |

| Guangxi Foxi Jewelry | Wuzhou, Guangxi | Hypoallergenic plated brass/alloy, bulk orders |

| Fanny Jewelry | Dongguan, Guangdong | Tungsten, carbide, men’s earrings, durable finishes |

| Azone Jewelry | Yiwu, Zhejiang | Alloy, multi-layer plating, mass fashion SKUs |

| DG Jewelry | Dongguan, Guangdong | Cartilage, helix, piercing lines, surgical steel |

| Paradise Jewelry | Yiwu, Zhejiang | Rhinestone, high-volume fashion earrings, festival / party lines |

MOQ, lead time & pricing tiers

These are typical ranges for custom orders; each project still needs a final quote.

| Manufacturer | Typical MOQ (per style) | Std. Lead Time (mass) | Pricing Tier (USD) | Best For |

|---|---|---|---|---|

| Dongguan HonHo Jewelry | 50–100 pcs | 20–30 days | Mid (premium vs low-MOQ) | Small brands needing quality + flexibility |

| Yiwu Gemnel Jewelry | 100–300 pcs | 20–35 days | Mid | Bridal & CZ-focused brands |

| TALMUD | 100–500 pcs | 25–35 days | Low–Mid | Themed / souvenir drops |

| Nendine | 100–200 pcs | 25–35 days | Mid | Sustainable hoops & studs OEM |

| Beyaly Jewelry | 50–150 pcs | 25–40 days | Mid–High | Higher-end stainless & silver |

| Very Selection | 200–500 pcs | 20–30 days | Low–Mid | Fashion / trend private label |

| Teemtry | 50–120 pcs | 15–25 days | Low | Low-budget CZ drops |

| Wuzhou Messi Gems | 50–100 pcs | 30–45 days | Mid–High | Gemstone / premium lines |

| Guangxi Foxi Jewelry | 200–1000 pcs | 20–30 days | Low | Bulk hypoallergenic supply |

| Fanny Jewelry | 100–300 pcs | 25–35 days | Mid | Men’s / unisex tungsten & carbide |

| Azone Jewelry | 300–1000 pcs | 20–30 days | Low | Mass fashion retailers |

| DG Jewelry | 100–300 pcs | 25–35 days | Mid | Piercing studios & cartilage brands |

| Paradise Jewelry | 300–1000 pcs | 15–25 days | Low | High-volume rhinestone fashion |

If you’re a smaller brand, you’ll usually get more flexibility on MOQs and design tweaks from manufacturers that explicitly focus on jewelry manufacturers for small business, like Dongguan HonHo Jewelry, which is built to support low-MOQ custom runs and structured gold-filled and plating options.

Certifications & niche strengths

| Manufacturer | Key Certifications* | Niche Strengths |

|---|---|---|

| Dongguan HonHo Jewelry | ISO-like internal QC, material test reports | Small-batch OEM/ODM, titanium, hypoallergenic, detailed QC |

| Yiwu Gemnel Jewelry | Basic factory audits, material reports | Bridal / CZ sets, matching collections |

| TALMUD | Export-compliant, social audits (select buyers) | Themed, branded, souvenir programs |

| Nendine | Material test reports, sustainability claims | Eco positioning, recycled metals, minimalist designs |

| Beyaly Jewelry | Material test reports, SGS on request | Higher-end finishes, custom molds for logos |

| Very Selection | BSCI with some clients | Fast fashion trends, private label development |

| Teemtry | Basic compliance docs | Low MOQ, fast sampling, CZ fashion |

| Wuzhou Messi Gems | Gem reports (for stones), factory audits | Gemstone sourcing + setting |

| Guangxi Foxi Jewelry | Material test reports for nickel/lead | Hypoallergenic bulk supply |

| Fanny Jewelry | Material & hardness reports | Tungsten/carbide engineering |

| Azone Jewelry | Basic audits, plating tests | Large SKU count, rapid new style rollout |

| DG Jewelry | Material test reports, piercing-grade focus | Cartilage & helix, small-gauge specialization |

| Paradise Jewelry | Basic factory audits | Party / festival rhinestone lines at scale |

*Always request up-to-date certificates, lab tests (especially nickel-free and lead-free), and, if you’re selling in the EU or US, confirm they align with your market’s regulations.

In practice, I pick 2–3 factories that fit my material + MOQ + niche combo, then pressure-test them with paid samples and small trial orders before locking in long-term deals.

Step-by-step guide to working with Chinese earring manufacturers

If you want to lock in a reliable custom earring OEM partner in China for 2026 and beyond, you need a clear process. Here’s how I’d run it from first contact to scaling orders.

1. How to vet custom earring suppliers in China

Start by filtering fast, then go deep on due diligence:

- Shortlist by basics

- Location: Dongguan, Guangzhou, Shenzhen, Yiwu, Wuzhou are key jewelry hubs.

- Materials: titanium, stainless steel, brass, sterling silver, CZ, pearls, gemstones, etc.

- Services: OEM/ODM, 3D design, CAD, sampling, private label packaging.

- Check public proof

- Years in business, export markets, and product focus (e.g. hypoallergenic stud earrings, cartilage jewelry, bridal custom earring ODM).

- Factory images, production lines, plating lines, and testing equipment.

- Certifications: ISO, BSCI/SMETA, nickel-free/lead-free test reports (REACH, CA Prop 65, etc.).

- Ask for hard data

- Latest lab reports for nickel release, lead, cadmium.

- Main customers or markets (EU, US, Middle East, Latin America).

- Real production capacity (pairs/month), peak season capacity, and average defect rate.

- Run a small litmus test

- Request a quick drawing quote and sample quote for 1–2 SKUs.

- Score them on response time, clarity, and how they handle your specs.

If you need a reference for what a structured OEM setup looks like, check how a mature partner describes their full jewelry manufacturing and OEM process—that’s the level of transparency you want.

2. Negotiating MOQ, samples, and payment terms

Your goal is to keep risk low while still being a good client to your factory:

- MOQ (minimum order quantity)

- For stainless steel / alloy fashion earrings: MOQs of 100–300 pairs per style are common.

- For gold-plated, titanium, or gemstone earrings: expect higher MOQs or higher unit prices.

- Tactics to lower MOQ:

- Share molds or components across multiple styles.

- Start with fewer colors or sizes.

- Commit to a roadmap (e.g. “If V1 sells, we place a reorder in 60 days”).

- Samples

- Ask for existing samples to verify base quality and plating first.

- Then move to custom samples with your logo, thickness, and stone settings.

- Clarify: sample fees, lead time (usually 7–20 days), and whether fees are refundable on bulk order.

- Payment terms

- Standard for new buyers: 30% deposit, 70% before shipment.

- For bigger/long-term orders: you can negotiate better terms after a few successful rounds.

- Always use secure channels (bank transfer to company account, or platform escrow early on).

3. Logistics, duties, and compliance for jewelry imports

Don’t leave shipping and compliance to the last minute—you’ll pay for it later:

- Logistics options

- Express (DHL/UPS/FedEx): fastest, best for samples and small batches.

- Air freight: mid-volume, quicker but more expensive than sea.

- Sea freight: best for large orders; build in extra lead time.

- Incoterms

- EXW/FOB: you handle freight and customs via your forwarder.

- DDP: some suppliers can quote door-to-door including duties—handy for startups with no logistics team.

- Duties and HS codes

- Confirm HS code for your earring materials (base metal, silver, gold-plated, etc.).

- Ask your broker to estimate duties + VAT/GST before final pricing decisions.

- Compliance

- For EU/US markets, insist on:

- Nickel-free or low-nickel standards for hypoallergenic jewelry.

- Lead and cadmium limits compliant with your market.

- Get copies of test reports with your product name or SKU on them, not just generic lab reports.

- For EU/US markets, insist on:

4. Scaling orders and diversifying suppliers for 2026

Once your first designs are selling, plan your scaling strategy early:

- Lock in your “A” factory

- Standardize specs (material, thickness, plating microns, stones) so you can reorder fast.

- Build a simple QC checklist and sign it off with the factory.

- Scale volume smartly

- Move from 100–300 pairs per style to 500–2000+ as you see data from your store/marketplace.

- Reserve capacity for key seasons (Q4, Valentine’s, wedding season) at least 2–3 months ahead.

- Diversify to cut risk

- Use a second factory for:

- Different materials (e.g. titanium hoops at one, brass fashion drops at another).

- Different segments (cartilage and helix piercing at one, bridal CZ drops at another).

- Keep molds, CAD files, and artwork backed up on your side, not just at the factory.

- Use a second factory for:

- Systematize communication

- Move product discussions to WeChat with clear threads by project/SKU.

- Use simple tracking sheets for: design stage, samples, POs, production, inspection, shipping.

If you want a benchmark for what solid OEM cooperation can look like by the time you’re scaling, study how specialized partners present their OEM jewelry capabilities—you’ll know what to expect and what to ask for.

Common sourcing pitfalls and pro tips

When you source custom earrings OEM in China, most problems come from rushing, vague specs, or chasing the cheapest quote. I keep it simple:

- Don’t skip factory background checks – verify business license, export history, and ask for real production photos, not just glossy catalogs.

- Avoid “too good to be true” pricing – ultra‑low quotes usually mean weak plating, poor stones, or unstable QC.

- Lock specs in writing – thickness, base metal, plating microns, stone grade, post type, packaging. No assumptions.

- Always run a paid sample round before placing bulk orders, especially for new SKUs or new finishes.

Quality, nickel-free testing, and hypoallergenic checks

If you sell in the US, EU, or UK, nickel and heavy metal limits are non‑negotiable. I treat this as a system, not a one‑time check:

- Specify hypoallergenic materials upfront: 316L stainless, titanium, sterling silver, or certified nickel‑free alloys.

- Require test reports: ask for recent EN 1811 (nickel release) or equivalent lab reports with your company / product name where possible.

- Do random 3rd‑party testing every few batches through labs like SGS, BV, TUV – especially for gold‑plated and alloy earrings.

- Check plating structure: base metal + barrier layer (e.g. palladium) + gold / rhodium. This matters more than color alone. You can also dig into guides like how serious gold-plated jewelry manufacturers control plating thickness to set your own standards.

Managing lead times, peak seasons, and QC

Custom earring OEM timelines move fast when you plan ahead, and painfully slow when you don’t:

- Know the real lead times:

- Samples: 7–20 days (depending on CAD, molds, stones)

- Bulk: 25–45 days after deposit, longer in Q4

- Plan around peak seasons: before Chinese New Year and “11.11” / holiday runs, capacity gets tight and QC slips if you push too hard.

- Build QC into the schedule:

- Pre‑production sample approval (golden sample)

- In‑process checks for plating and stone setting

- Final random inspection (AQL) before balance payment

- Use clear QC checklists: photo references, accepted color tolerance, allowed defect rate, packaging requirements. Don’t leave “quality” as a vague word.

Communication, WeChat, and budgeting for revisions

Most issues with Chinese earring manufacturers come from unclear communication, not bad intent. I handle it like this:

- Move key talks to WeChat once you’ve vetted the supplier – it’s faster for photos, videos, and quick clarifications.

- Always follow up with written summaries by email or WeChat message: what’s confirmed, what changed, who pays for what.

- Send visual references (screenshots, sketches, Pantone codes, sample photos) instead of only text descriptions.

- Budget for revisions:

- Expect 1–2 rounds of sample tweaks for new collections.

- Set a revision budget per SKU so design changes don’t destroy your margins.

- Use small test orders to fine‑tune designs before you scale.

If your line leans heavily on stainless steel or gold‑tone pieces, it’s worth understanding how a serious stainless partner thinks about things like stainless steel jewelry styling and finishing so you can speak the same language and get cleaner results on the first try.

FAQs about sourcing custom earrings from China

MOQ, lead time & pricing for custom earrings

Q: What’s a realistic MOQ for custom earrings in China?

- Stainless steel / alloy fashion earrings: 100–300 pairs/design with low MOQ factories

- Sterling silver, titanium, cartilage/helix: usually 50–100 pairs/design

- Gold-plated / vermeil / solid gold: many ask 30–50 pcs per SKU minimum

Q: Typical lead time for custom earring OEM orders?

- Sample development: 7–15 days (longer if fully custom CAD + stones)

- Mass production: 20–35 days after sample approval and deposit

- Peak seasons (before Christmas, Valentine’s Day, 11.11): add 7–10 days buffer

Q: How is pricing usually structured?

Factories price based on:

- Metal (alloy < stainless < 925 silver < titanium < gold)

- Plating (thickness in microns, IP vs normal electroplating)

- Stones (CZ vs lab-grown vs natural gems vs pearls)

- Order quantity (clear price breaks at 100 / 300 / 500 / 1,000 pairs)

If you’re new, start by asking for a tiered price list:

- 100 / 300 / 500 / 1,000 pairs per design

- Different material options (e.g. stainless vs 925 silver version)

Ensuring quality control from overseas

Q: How do I control quality if I’m not in China?

- Always start with pre-production samples and keep one in your office as a golden sample

- Use third-party inspection (SGS, BV, QIMA, local QC agents) before shipment

- Ask factories for detailed specs in writing: metal, plating microns, stone grade, tolerance, packaging

For reference, I often send factories visual benchmarks from pages like this wholesale earrings catalog to align on finishing and style expectations: premium stainless steel and titanium earrings styles.

Key checks to confirm:

- Nickel-free and lead-free declarations + optional lab test

- Plating thickness (e.g. 0.03–0.05 μm flash vs 0.1–0.3 μm fashion vs 1–2 μm vermeil)

- Stone setting strength, earring backs type, and weight comfort

Gold‑plated & premium material minimums

Q: Why are MOQs higher for gold-plated and premium metals?

Because factories need to:

- Hit minimum plating bath volumes

- Buy gold solution and premium metals in bulk

- Allocate more skilled labor for micro‑pavé and stone setting

Typical MOQs:

- Gold-plated brass / stainless: 50–100 pairs per color per design

- Vermeil (thick gold over 925 silver): often 30–50 pairs per SKU

- Solid gold / 14K / 18K: small batch possible, but unit price is high and deposits are strict

Q: How do I verify 925 silver or gold specs?

- Request material certificates and stamping details (e.g. 925, 585, 750)

- You can also refer to guides on what 925 silver markings actually mean when aligning with suppliers: meaning of 925 Italy and other silver jewelry hallmarks.

Sustainability & ethical sourcing

Q: Can Chinese earring manufacturers offer sustainable options?

Yes, but you need to ask very directly for:

- Recycled metals (recycled stainless, recycled 925, or certified gold where possible)

- Lab-grown stones or high-grade CZ instead of mined gems

- Lead-free / nickel-safe plating systems

- Eco-friendlier packaging (paper boxes, FSC-certified cartons, no excess plastic)

Q: What about ethical and social compliance?

When you care about ethics, request:

- Copies of BSCI, SEDEX, ISO 9001, ISO 14001, or local social audits

- Clear policy statements on no child labor, working hours, and wage compliance

- Supplier transparency on subcontractors, especially for stone setting and plating

If sustainability is part of your brand story, lock it into the PO and tech pack (e.g. “recycled stainless only”, “nickel-free plating”, “no PVC packaging”) so it’s not just a verbal promise.

share this recipe:

Still hungry? Here’s more

Gold Filled vs Vermeil Guide Differences Durability and Value

What Is Gold Filled Jewelry? Gold filled jewelry is my go-to recommendation when someone wants

How Much for a Gold Necklace 2026 Price Guide and Tips

Understanding Gold Purity and Karats When people ask “how much for a gold necklace?”, the

Spiritual Jewelry Symbols Guide- Meanings and How to Choose

How to Use This Spiritual Jewelry Symbols Guide Spiritual jewelry only works for you when

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.