How to Dodge Jewelry Sourcing Risks from China: Your 2026 Playbook

The allure of jewelry sourcing from China is undeniable. It’s a global hub of manufacturing, offering unparalleled scale, advanced technology, and competitive pricing. For a brand looking to scale, the potential for profit is immense.

Let’s face it, getting your jewelry made in China is tempting. They’re a huge manufacturing center with awesome tech and prices that are hard to beat. If you want to grow your brand, the chance to make some serious cash is there.

But, let’s be real, the fear of getting ripped off is also real.

You’ve heard the stories: rings that turn your finger green, real silver that’s anything but, or factories that disappear with your money. These aren’t just stories; they’re real problems that can kill a business.

Think of this guide as your treasure map. We’re not going over the basic stuff you can find anywhere. We’re digging into the know-how that separates brands that last from those that crash and burn. We’ll show you how to turn those scary China sourcing risks into a reason you’re better than everyone else.

By the time you’re done reading, you’ll know how to check out a manufacturer, what technical questions to ask, and how to make sure your quality is top-notch, so your brand stays spotless.

Why Getting Jewelry from China is Both Great (and a Bit Scary)

China’s manufacturing scene is a mixed bag. On one hand, they have the best production lines, making everything from fancy 925 silver to tons of 316L stainless steel pieces. On the other, it’s a huge place, and figuring out who’s a real factory, who’s just a middleman, and what’s real versus fake can be a full-time job.

The good part is the size and the tech. Places like Dongguan have spent a ton on machines that can do things like perfect metal pouring and top-notch plating, which is hard to find or super expensive somewhere else.

The bad stuff usually comes from not being open and trying to cut corners. Watch out for:

- Fake Materials: Using cheap metal instead of stainless steel, or bad silver.

- Stolen Designs: Seeing your stuff on someone else’s site.

- Bad Quality: The sample is great, but the order is messed up.

To make sure this doesn’t happen, you need to know your stuff and think long-term, not just about the price.

Risk #1: Is That Material Real?

The biggest worry is fake materials. People expect to get what they paid for. If they don’t, your brand is toast.

316L vs. 304 Stainless Steel: What’s the Deal?

If you’re sourcing stainless steel jewelry, you’ll see two main types: 304 and 316L.

- 304 Stainless Steel: It is common, cheap, and used a lot. It resists rust, but it has more nickel and can get spots or rust over time, especially with salt water or strong chemicals.

- 316L Stainless Steel: This is what surgeons use. It is super resistant to rust and won’t turn your skin green. It’s the best choice for jewelry that lasts.

A sneaky factory might quote you for 316L but use 304 to save money. You can’t see the difference, but your customers will notice in a few months.

How to Check Silver (XRF Test)

When buying 925 silver, you want to know it’s really 92.5% silver. Is it mixed with something cheap or gross?

The old way is the acid test, but now, the best factories use something called an XRF (X-ray Fluorescence) Analyzer. It’s quick and doesn’t hurt the jewelry.

This machine tells you exactly what’s in the metal. If your factory can’t give you an XRF report or show you a video of them testing your jewelry, that’s a bad sign. If you know what you’re doing, you’ll demand this.

Risk #2: Will It Turn Green? The Plating Problem

Nothing kills a jewelry brand faster than turning skin green or looking old quickly. The plating is what protects the jewelry and makes it look good, so it needs to be done right.

PVD: The Best Way to Plate for Waterproof Jewelry

Most jewelry uses a cheap plating method with water and chemicals. It’s fast, but it flakes, fades, and turns quickly.

A much better way is PVD (Physical Vapor Deposition). It’s a fancy process that happens in a vacuum. The gold sticks to the metal on a tiny level.

Alt: A machine that makes jewelry waterproof with gold.

| Feature | Cheap Plating | PVD Plating |

|---|---|---|

| Lasts | Not long (Fades fast) | Way longer (Can last 10x longer) |

| Waterproof? | Nope (Turns easy) | Yep (Waterproof and won’t turn) |

| How Thick? | Thin | Thicker |

| Bad for Earth? | Yes (Uses gross stuff) | No (Good for earth, no gross stuff) |

If you want jewelry that lasts and is waterproof, you need PVD plating. Factories that have their own PVD machines, like HonHo Jewelry, are a safe bet.

Why In-House Plating Matters

If a factory doesn’t do its own plating, they can’t control the quality. They have to rely on someone else.

If the factory does the plating, they control everything.

- Same Every Time: Everything is done the same way.

- Fast: Samples and orders get done faster.

- Cheaper: No middleman costs.

- Someone to Blame: The factory is responsible for the plating.

If you’re trying to find a good jewelry maker in China, always ask if they do their own plating.

Risk #3: Did They Mess Up My Design?

Your design is what makes you unique. If the final product doesn’t look like what you wanted, you have a problem.

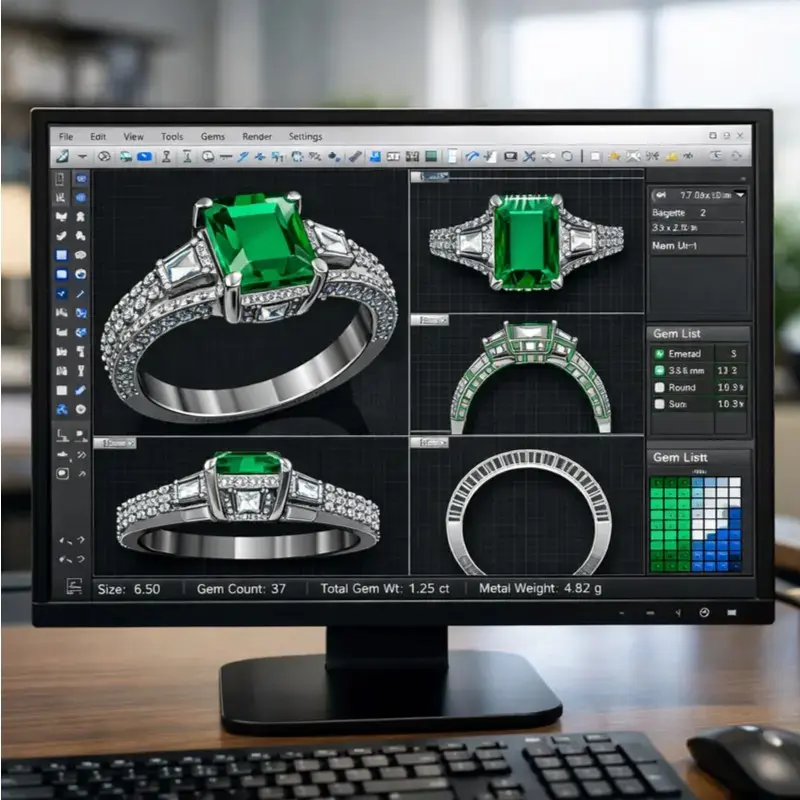

Use CAD and 3D to Lock in Your Vision

Don’t just send a drawing and hope for the best. Now, jewelry making starts with computers.

CAD (Computer-Aided Design) is the first thing you need. The factory should turn your idea into a model on the computer. This is what they’ll use to make the jewelry. Before they start, you should get:

- CAD Files: To see everything closely.

- 3D Pictures: To see what it will look like

- Weight Guess: To know how much it will cost.

When you say the CAD file is good, everyone knows what to expect.

Make a Sample Fast (7-20 Days)

After the CAD, you need a sample. If the factory can get you a sample fast (like in 7-20 days), that means they’re good at what they do. They use 3D printers to make models quickly.

This is important because you can check the product and see if it’s right before you spend a ton of money.

Risk #4: Who Owns the Design?

You need to protect your ideas and designs. Design theft is a big problem in the jewelry world.

Who Owns Your Jewelry Designs?

When you pay for a design, make sure you own it and the computer file. Sometimes, factories will use your design to make jewelry for other people, which means your special design is no longer special.

Your agreement should say:

- You own the design and the file.

- They will keep it safe and only use it for you.

- They won’t give it to anyone else.

A good jewelry maker in China will have rules about protecting designs and will sign an agreement before you show them anything.

Protect Your Designs

Besides the agreement, the best way to protect yourself is to work with people you can trust. Factories that work with big brands know how important designs are and have ways to protect them. Ask them how they keep your designs safe.

Risk #5: Playing by the Rules (US/EU)

If you’re selling jewelry in the US or Europe, you need to follow certain rules. If you don’t, you could get fined or have your products taken away.

Know the Rules About Harmful Stuff

The main rules are about lead, nickel, and cadmium.

- Nickel: Some people are allergic to nickel. The EU has rules about how much nickel can come off jewelry.

- Lead and Cadmium: These metals are dangerous, and there are rules about them in the US and Europe.

Your factory needs to make sure everything they use is lead-free and nickel-free. It’s not an option; it’s the law.

Why Certificates Aren’t Enough

Factories should give you certificates, but those can be fake. The best thing to do is:

- Test Each Batch: Have a lab test samples from your order.

- Check Records: Ask to see the factory’s records of testing the materials they use.

This shows you’re serious and that you know what you’re doing when it comes to jewelry sourcing.

How to Check Out a Jewelry Maker Like a Pro

The biggest mistake you can make is working with the wrong factory. You need to be able to tell a real factory from a fake one.

Checklist: Factory vs. Middleman

| Feature | Middleman | Real Factory |

|---|---|---|

| Price | More (They add a fee) | Cheaper |

| Order Size | Flexible (Costs more) | Also Flexible (Especially if you work with them long-term) |

| Know-How | Not much | A lot (Can talk about plating, testing, and designs) |

| Factory Tour | No | Yes |

| Custom Designs | Slow, mistakes happen | Fast, can talk to designers |

Ask for the Right Proof (Factory Pictures, Records)

Don’t just ask for a business license. Ask for proof that they can do what they say they can do:

- PVD Machine Photos: Ask for a picture of their PVD machine with the date on it.

- Testing Records: Ask for their testing records from the last month.

- Where Are They?: A real jewelry maker in China will be in a place like Dongguan or Shenzhen.

Why Quality Control is Your Best Friend

Checking the quality of the jewelry should be something you do all the time, not just once.

Check Before, During, and After

- Check Before: Check the materials when they come in (are they real?) and make sure the design is right.

- Check During: Check the jewelry after it’s been made but before it’s been plated.

- Check After: Check the finished product to see if there are any problems.

Know the Quality Rules (AQL)

AQL is a way to measure quality. For jewelry, a normal AQL is AQL 2.5/4.0. This means:

- Big Problems (Safety): None allowed.

- Medium Problems (Bad Product): Only 2.5% allowed.

- Small Problems (Doesn’t Look Great): Only 4.0% allowed.

A good jewelry maker in China will know about AQL and use it.

Location, Location, Location (Dongguan is King)

Where your factory is located is really important.

China has lots of manufacturing areas, but for good jewelry, the Pearl River Delta, especially Dongguan, is the best.

Dongguan is called the Silicon Valley of Jewelry because:

- Everything is Close: Factories, material sellers, and plating companies are all nearby, which makes things faster and easier.

- Good Workers: Lots of skilled people who know how to make jewelry.

- New Tech: Factories in Dongguan use the latest tech.

Picking a factory in this area, like Dongguan HonHo Jewelry, is a good move.

Top 5 Tips for Smooth Sourcing

Here are five tips to help you have a good time sourcing jewelry.

- Start Small: Don’t order a ton right away. A factory that lets you order a small amount is confident in their work and wants to build a relationship. This way, you don’t have to worry about having too much stuff you can’t sell.

- Make Friends: Think of your factory as a friend, not just someone you buy from. Friends will give you better prices, take care of your orders, and share ideas.

- Get It In Writing: Make sure your agreement covers payment, shipping, designs, quality, and materials.

- Focus on a Few Good Factories First: Work with one or two factories that you trust. This will give you more power. Once you’re set, you can think about working with others.

- Be Open: A good factory will show you their factory, their machines, and their records. If they don’t, go somewhere else.

In Conclusion: Make Risks Work for You

Getting jewelry from China has risks, but you can handle them. You need to stop worrying about the cheapest price and start looking for expertise, authority, and trust.

When you ask for things like material testing and in-house plating, you not only avoid problems but also make your brand better. You can tell people your products are waterproof and safe to wear.

This turns your supply chain into something that makes you stronger.

Ready to Grow Your Jewelry Brand the Right Way? (CTA)

Ready to start sourcing jewelry the right way?

Stop worrying about fake materials. Start working with a factory that knows what they’re doing.

Dongguan HonHo Jewelry is a top jewelry maker in China that makes great 316L stainless steel jewelry, brass, and 925 silver jewelry. We have our own plating machines. We let you order small amounts and make samples quickly.

Contact us today to talk about your jewelry needs and get a free design consultation!

China Jewelry Sourcing: Your Questions Answered

What’s the worst thing that can happen when sourcing jewelry from China?

The worst thing is getting bad quality or fake materials. This means getting jewelry made of cheap stuff or plating that wears off quickly. You can prevent this by having the jewelry tested and working with factories that do everything themselves.

What is PVD plating, and why is it better?

PVD plating is a process that makes the gold stick to the metal really well. It’s better than cheap plating because it lasts longer and won’t wear off.

How can I tell if a factory is real?

Ask to see their machines and factory floor. A trading company will only show you samples.

What’s a good order size for custom jewelry?

For good custom jewelry, you can order as few as 30 pieces per design. If a factory only lets you order a ton, they might be a trading company.

What is XRF testing, and do I need it?

XRF testing is when you use a machine to check what a metal is made of. You should always do this to make sure you’re getting what you paid for.

How long should it take to get a sample?

It should take about 7 to 20 days to get a sample. If it takes longer, the factory might not be very good.

What are the rules about jewelry in the US and Europe?

The main rules are about lead, nickel, and cadmium. Make sure your jewelry doesn’t have these things in it.

Why is Dongguan a good place to source jewelry?

Dongguan has lots of factories and suppliers close together. This makes it easier to get things done quickly and make sure the quality is good.

References

1.Jewellery Coating Explained: Electroplating, Platinum Polish & PVD

2.Understanding REACH Regulation

3.Strategic China Sourcing – 5 Mistakes and How to Avoid Them

share this recipe:

Still hungry? Here’s more

Top 50 Jewelry Brands Worth to Buy 2026: The Definitive Investment & Style Encyclopedia

The global jewelry market in 2026 is a fascinating landscape where centuries-old heritage meets cutting-edge

Why Brass Jewelry Wholesale Fits Fashion Brands: The Strategic Guide for 2026

In the rapidly evolving landscape of the global fashion industry, the demand for affordable luxury

Enamel Jewelry Wholesale: Adding Color to Your Brand’s Collections

In the ever-evolving world of fashion, color has become the ultimate tool for self-expression. For

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.