Best Steel Jewelry Manufacturers 2026: Expert Guide

Have you ever wondered what it takes to create the stunning steel jewelry you see in stores? Finding a reliable steel jewelry manufacturer can feel like searching for a needle in a haystack. You want quality, durability, and style, but it’s hard to know who to trust. Many jewelry brands and shoppers face the same challenge: finding a partner who can deliver beautiful, long-lasting pieces without breaking the bank.

This guide is here to help you navigate the world of steel jewelry manufacturing. We’ll explore the top manufacturers in the industry, uncover the secrets behind their production processes, and explain what makes steel the go-to material for modern jewelry. Whether you’re a growing brand looking for a production partner or a savvy shopper wanting to understand what makes a quality piece, you’ve come to the right place. With over 15 years of experience, we at HonHo Jewelry are excited to share our knowledge and help you make an informed choice.

What is Steel Jewelry Manufacturing?

Steel jewelry manufacturing is the process of creating jewelry from stainless steel, a durable and versatile metal alloy. Unlike traditional jewelry making, which often involves softer metals like gold or silver, working with steel requires specialized equipment and techniques. The process is a blend of modern technology and skilled craftsmanship, transforming raw steel into beautiful, long-lasting accessories.

A key material used is 316L stainless steel, often called surgical steel. This specific grade is chosen for its excellent corrosion resistance and hypoallergenic properties, making it safe for sensitive skin . The manufacturing process itself can involve several methods, including precision CNC machining, lost-wax casting, and laser engraving. Each step is carefully controlled to ensure the final product meets high-quality standards. From initial design to final polishing, a reputable steel jewelry manufacturer will focus on creating pieces that are not only stylish but also built to last.

A modern steel jewelry manufacturing facility equipped with precision CNC machines and quality control stations

Top Steel Jewelry Manufacturers

When it comes to finding a reliable steel jewelry manufacturer, it’s important to look for a partner who combines quality, innovation, and excellent service. Here are some of the top manufacturers in the industry:

1. HonHo Jewelry (Dongguan, China)

HonHo Jewelry is a manufacturer with over 15 years of experience in custom jewelry manufacturing. The company operates a state-of-the-art facility in Dongguan, China, equipped with an in-house PVD (Physical Vapor Deposition) vacuum plating facility. Key capabilities include a 24-month warranty on PVD coatings, flexible minimum order quantities suitable for various brand sizes, and an in-house design team. The manufacturer reports maintaining quality control standards with a defect rate of less than 0.5%, which can be verified through direct communication with the company.

2. Kesheen (China)

Kesheen is a second-generation family business that has made a name for itself in the custom stainless steel jewelry market. They focus on using 316L surgical stainless steel and offer PVD coating for added durability. With a minimum order quantity of 200 pieces, they cater to brands looking to produce in larger volumes. Their commitment to sustainability is also a key part of their brand, as they use recycled materials in their production process.

3. Monera Design (Thailand)

Based in Bangkok, Monera Design has been in the fashion jewelry business since 2011. They offer a massive inventory of over 5,000 designs, making them a great choice for retailers looking for a wide variety of styles. They specialize in 316L stainless steel and have a team with over 30 years of combined experience. Their focus is on providing trendy, high-quality designs that are ready to ship.

4. Stuller (USA)

Stuller is a major player in the US fine jewelry market. While they work with a variety of materials, their focus is on precious metals and diamonds. They offer a wide range of educational resources and customization services, making them a valuable partner for jewelers. However, their primary focus is not on stainless steel, so their offerings in this area may be more limited.

Manufacturing Methods Explained

The creation of steel jewelry is a fascinating process that combines technology and artistry. While methods can vary, most modern manufacturers use a combination of the following techniques:

First, CNC (Computer Numerical Control) machining is a subtractive process where high-precision machines, guided by computer software, carve designs from a solid block of stainless steel. As seen in industry videos, these machines can operate at incredibly high speeds (up to 36,000 RPM) and use coolant to ensure every cut is precise . This method is ideal for creating intricate and detailed designs with tight tolerances.

Next, lost-wax casting is a traditional method still used for more complex and organic shapes. It starts with a wax model of the jewelry piece, which is then encased in a plaster-like material to create a mold. The wax is melted out, and molten stainless steel is poured in. It’s a great technique for producing multiple identical pieces at once.

For adding fine details, logos, or custom text, manufacturers use laser engraving. A high-powered laser etches the design onto the surface of the steel with incredible accuracy. This process is often guided by precise jigs to ensure every piece is identical.

Finally, once the basic shape is created, each piece goes through multiple stages of polishing and finishing to achieve a smooth and shiny finish. This can be a manual process done by skilled artisans or an automated one, depending on the desired look.

PVD Coating Technology: The Secret to Long-Lasting Color

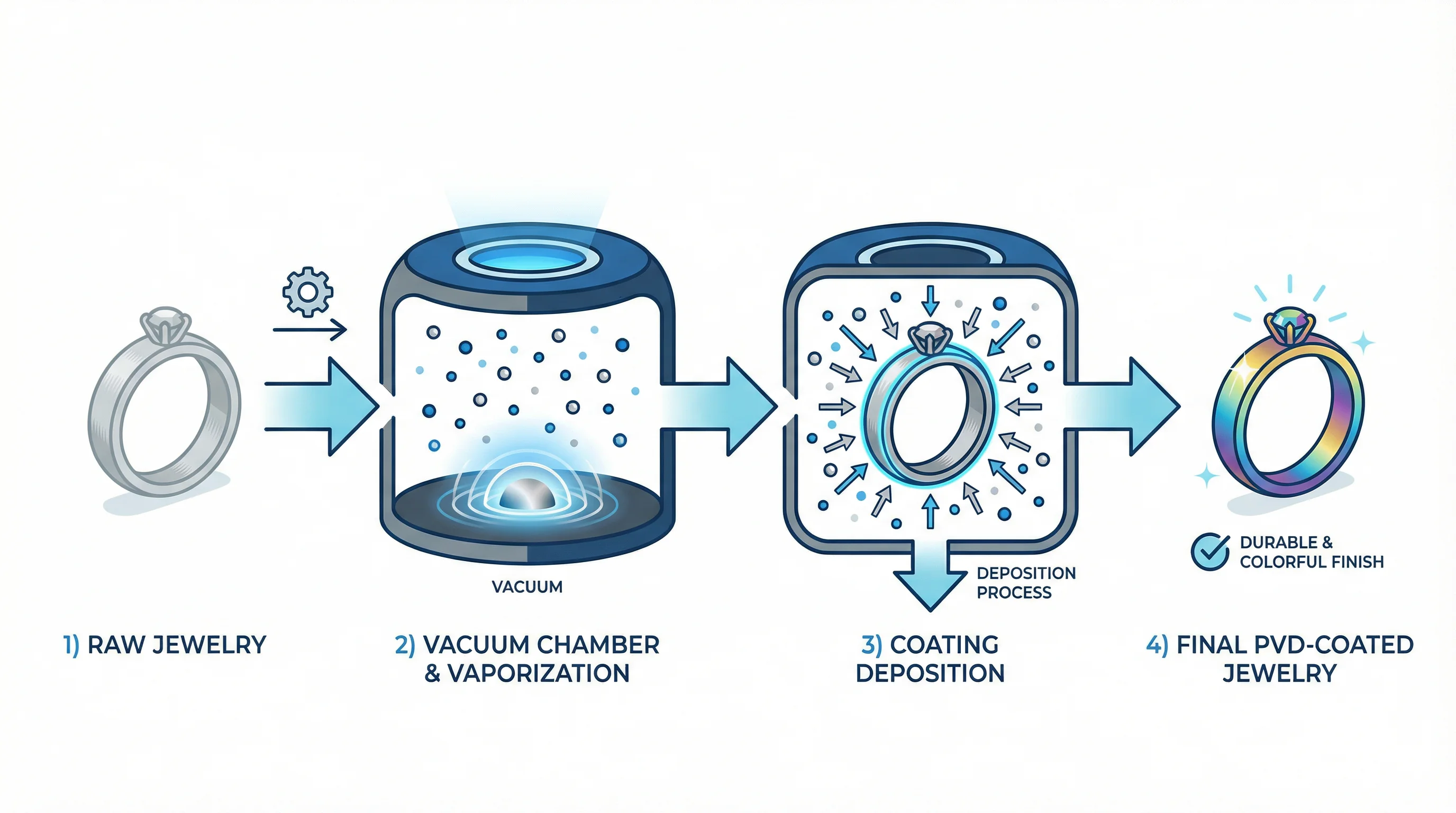

One of the most exciting innovations in steel jewelry is PVD (Physical Vapor Deposition) coating. This is a high-tech process that creates a durable, long-lasting colored finish on stainless steel. Unlike traditional plating methods that can easily chip or fade, PVD coating is incredibly resilient.

The process takes place in a vacuum chamber where a solid material, often a metal like titanium, is vaporized and then deposited onto the jewelry piece as an ultra-thin layer . This creates a strong bond with the steel, resulting in a finish that is resistant to scratches, corrosion, and tarnish. That’s why at HonHo Jewelry, we are confident enough to offer a 24-month warranty on our PVD-coated pieces. It’s the secret to creating colorful jewelry that truly stands the test of time

The PVD coating process: from raw jewelry to durable, colorful finish

Material Properties & Benefits: Understanding Stainless Steel Grades

When selecting stainless steel for jewelry, understanding the different grades is crucial for ensuring both quality and safety. The two most common austenitic stainless steels are Type 304 and Type 316L.

A common misconception is that 316L stainless steel is superior because it has less nickel. In fact, the opposite is true. According to industry standards from organizations like the Nickel Institute and ASTM International, 316L grade actually contains a higher percentage of nickel (10-14%) compared to 304 grade (8-10.5%) .

The key to 316L’s superior performance, especially in jewelry, is the addition of 2-3% molybdenum. This element is not present in 304 steel and is what provides enhanced resistance to pitting corrosion from chlorides, such as sweat and saltwater . This is why 316L is often referred to as “surgical steel” or “marine-grade steel.”

While 316L has more nickel, it is generally considered more hypoallergenic. This is because the molybdenum and higher chromium content create a more stable and robust passive layer on the steel’s surface, which significantly reduces nickel leaching and prevents skin irritation for most people . Therefore, 316L remains the preferred choice for high-quality, durable, and biocompatible jewelry.

Key properties of 316L stainless steel jewelry

Here’s a quick comparison of how stainless steel stacks up against other popular jewelry materials:

| Feature | Stainless Steel (316L) | Titanium | Gold (14k) | Sterling Silver (925) |

|---|---|---|---|---|

| Hypoallergenic | ✅ Excellent | ✅ Excellent | Generally Good | ❌ Contains Nickel |

| Durability | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐ (Malleable) | ⭐ (Scratches Easily) |

| Corrosion Resistance | ✅ Excellent | ✅ Excellent | ✅ Excellent | ❌ Tarnishes |

| Affordability | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐⭐⭐ (High) | ⭐ (Low) | ⭐⭐⭐ (Medium) |

| Weight | Medium | Very Lightweight | Heavy | Heavy |

| Color Options | Silver, PVD Colors | Silver, Anodized Colors | Yellow, Rose, White | Silver |

Comprehensive comparison of jewelry materials: steel, titanium, gold, and silver

Quality Standards & Certifications: What to Look For

When choosing a steel jewelry manufacturer, it’s important to look for a partner who adheres to strict quality standards. Certifications are a great way to verify that a manufacturer is committed to producing safe, high-quality products. Here are a few to look for:

ISO 9001 is an international standard for quality management systems. An ISO 9001 certified manufacturer has demonstrated that they have a consistent process for producing high-quality products and are committed to continuous improvement.

For jewelry that will be in direct contact with the skin, it’s crucial that it meets standards for nickel release. In Europe, this is regulated by REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). A reputable manufacturer will be able to provide test reports showing that their products are compliant.

A trustworthy manufacturer should also be able to provide material certifications for the materials they use, confirming that they are using genuine 316L stainless steel. This ensures that you are getting a product that is both durable and hypoallergenic.

When evaluating any steel jewelry manufacturer, it’s important to request documentation for quality standards, material certifications, and defect rates. Reputable manufacturers should be transparent about their processes and willing to provide third-party test reports for nickel release compliance and material specifications.

Care & Maintenance Guide: Keeping Your Jewelry Beautiful

One of the best things about stainless steel jewelry is how easy it is to care for. Unlike silver, it won’t tarnish, and it’s much more scratch-resistant than gold. However, a little bit of care can go a long way in keeping your pieces looking their best.

To clean your steel jewelry, all you need is a soft cloth, some mild soap, and warm water. Simply mix a few drops of soap into the water, dip the cloth in, and gently wipe down your jewelry. For any hard-to-reach areas, you can use a soft-bristled toothbrush. Once you’re done, rinse the jewelry with clean water and dry it thoroughly with a soft cloth. Avoid using harsh chemicals or abrasive cleaners, as they can damage the finish, especially on PVD-coated pieces.

When you’re not wearing your jewelry, it’s a good idea to store it in a soft pouch or a separate compartment in your jewelry box. This will prevent it from getting scratched by other pieces. With just a little bit of care, your stainless steel jewelry will stay looking as good as new for years to come.

Essential tools for caring for your steel jewelry

Frequently Asked Questions (FAQs)

What is the best steel jewelry manufacturer?

The best steel jewelry manufacturer is one that combines quality, reliability, and excellent customer service. Look for a partner with a proven track record, positive reviews, and a commitment to using high-quality materials like 316L stainless steel. At HonHo Jewelry, we believe our 15+ years of experience and dedication to quality make us a top choice.

Is stainless steel jewelry hypoallergenic?

316L stainless steel is generally considered hypoallergenic for most people. While it contains a higher percentage of nickel than 304 steel (10-14% vs 8-10.5%), the molybdenum content and superior corrosion resistance create a stable passive layer that minimizes nickel leaching. This makes it a suitable choice for people with mild to moderate nickel sensitivity. However, individuals with severe nickel allergies should consult with a dermatologist or allergist before wearing any nickel-containing jewelry.

What is the difference between 304 and 316L stainless steel?

The primary differences between 304 and 316L stainless steel are composition and corrosion resistance. According to ASTM standards, 304 contains 8-10.5% nickel and no molybdenum, while 316L contains 10-14% nickel and 2-3% molybdenum . The molybdenum in 316L provides significantly enhanced resistance to pitting corrosion from chlorides, making it the superior choice for jewelry, particularly for items that will be exposed to sweat, saltwater, or other corrosive environments.

How long does steel jewelry last?

With proper care, stainless steel jewelry can last a lifetime. It is incredibly durable and resistant to scratches, tarnish, and corrosion. PVD-coated pieces are also very long-lasting, with the color remaining vibrant for many years.

What is PVD coating and how does it work?

PVD (Physical Vapor Deposition) is a modern coating process that creates a durable, colored finish on stainless steel. It takes place in a vacuum chamber where a material is vaporized and deposited onto the jewelry. The result is a finish that is much more durable than traditional plating.

Can steel jewelry be resized or repaired?

Due to its hardness, resizing stainless steel jewelry can be difficult and is often not possible. However, some simple repairs, like fixing a clasp, can be done by a skilled jeweler. It’s always best to check with the manufacturer for their specific policies on repairs.

How much does it cost to manufacture steel jewelry?

The cost of manufacturing steel jewelry varies depending on factors like design complexity, order quantity, and finishing options. Generally, steel jewelry is more affordable than gold or platinum. For custom orders, contact a manufacturer like HonHo Jewelry for a detailed quote.

What certifications should a steel jewelry manufacturer have?

Look for manufacturers with ISO 9001 certification for quality management, REACH compliance for nickel release standards, and material certifications for 316L stainless steel. These certifications ensure the manufacturer follows strict quality and safety standards.

Is steel jewelry better than gold jewelry?

Steel jewelry offers several advantages over gold: it’s more affordable, more durable, hypoallergenic, and requires less maintenance. However, gold has its own appeal with its classic look and investment value. The choice depends on your priorities and budget.

How do I choose a reliable steel jewelry manufacturer?

Look for manufacturers with extensive experience, positive customer reviews, quality certifications, transparent manufacturing processes, and flexible minimum order quantities. Request samples, check their warranty policies, and ensure they can provide material certifications.

Conclusion: Your Partner in Quality Steel Jewelry

Choosing the right steel jewelry manufacturer is a crucial step in building a successful jewelry brand or finding a piece you’ll love for years to come. By understanding the manufacturing process, the materials used, and the quality standards to look for, you can make an informed decision. Stainless steel offers an unbeatable combination of durability, style, and affordability, and with innovations like PVD coating, the design possibilities are endless.

At HonHo Jewelry, we are passionate about creating beautiful, high-quality steel jewelry. With our extensive experience, in-house design team, and commitment to quality, we are ready to help you bring your vision to life. Whether you are looking for a reliable manufacturing partner or a custom-designed piece, we invite you to get in touch with us. Let’s create something amazing together.

References

[1] “ASTM F136-13, Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401),” ASTM International, https://www.astm.org/f0136-13.html

[2] “Mass production process of stainless steel ring,” YouTube, Chengfen Factory, https://www.youtube.com/watch?v=n8sqvJEsemM

[3] “What is PVD Coating? Learn the Basics in this Webinar,” YouTube, VaporTech, https://www.youtube.com/watch?v=Dt60oeFoPaU

share this recipe:

Still hungry? Here’s more

The Unseen Hero: Why Earring Backings Define Quality Jewelry

Every jewelry brand owner knows the sinking feeling. A customer calls, distraught. They’ve lost one

Choosing the Best Jewelry Stone Setting for Mass Production

Selecting the right jewelry stone setting is one of the most pivotal decisions for any

Best Jewelry Stone Setting for Mass Production | HonHo

Choosing the best jewelry stone setting Choosing the best jewelry stone setting is one of

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.