Overcoming Barriers with Your Chinese Jewelry Supplier: The Ultimate 2026 Guide

In the fast-paced world of fashion, finding a reliable Chinese jewelry supplier is often the difference between a brand that scales and one that stalls. China remains the global powerhouse for jewelry manufacturing, offering unparalleled scale and technical expertise.

However, for many US-based brands, the journey is often fraught with “invisible barriers”—from quality inconsistencies to communication gaps that can lead to costly delays. When you partner with a Chinese jewelry supplier, you are not just buying products; you are entering into a long-term strategic alliance that requires trust, transparency, and technical alignment.

Every supplier has its own strengths, but finding one that aligns with your brand’s quality standards is the ultimate goal. According to Forbes, global supply chain transparency is becoming a top priority for luxury brands.

If you have ever felt like you were hitting a wall with your production, you are not alone. This guide is designed to pull back the curtain on the jewelry manufacturing industry in China. We will explore the technical “hidden” gaps that most suppliers won’t tell you about and provide actionable strategies to turn your relationship with a Chinese jewelry supplier into a powerful partnership.

Understanding the landscape of a manufacturing partner is the first step toward global success. A reliable partner will act as an extension of your team, ensuring that every piece meets your exact specifications. Industry experts at JCK Online emphasize that manufacturing consistency is the backbone of jewelry retail success.

The Invisible Barriers in Jewelry Sourcing

Sourcing from a Chinese jewelry supplier involves more than just sending a CAD file and waiting for a shipment. It is a complex dance of cultural nuances and technical precision. One of the most common barriers is the “Yes” trap. In Chinese business culture, “Mianzi” (face) is paramount.

A Chinese jewelry supplier might say “Yes” to a difficult design or a tight deadline not because they can definitely do it, but because they want to maintain a positive relationship. This cultural nuance is a critical factor when evaluating any potential partner. You need a partner that values long-term partnership over short-term gains. Research from Statista shows that the global jewelry market is projected to grow significantly, driven by online sales and custom designs.

To overcome this, you must move beyond simple email exchanges. Successful brands use detailed technical spec sheets and maintain constant, transparent communication channels with their Chinese jewelry supplier.

By setting clear expectations, you help your partner understand that honesty is more valuable than a polite “yes.” This builds a foundation of trust that is essential for any long-term collaboration. A transparent partner will always keep you informed of any potential issues before they become major problems.

Ethical sourcing standards, as outlined by the Responsible Jewellery Council, are essential for modern brand integrity.

Alt: Modern jewelry production line in a Chinese factory

Barrier 1: Quality Inconsistency & The “Golden Sample” Trap

We have all been there: the “Golden Sample” arrives, and it is perfect. But when the mass production order of 1,000 pieces lands in your warehouse, the finish is dull, or the stones are loose. This is the most significant barrier when working with a Chinese jewelry supplier.

Many brands struggle with this inconsistency, which is why choosing the right partner is so vital. A top-tier manufacturer will have systems in place to ensure that the quality of the first piece is identical to the ten-thousandth piece. This consistency is what makes a reliable manufacturer a valuable asset to your brand. Vogue Business reports that sustainable manufacturing is no longer optional for high-end fashion labels.

The Technical Insight: Why Mass Production Fails

The gap usually occurs during the transition from manual sampling to automated mass production. In many factories, samples are made by “Master Craftsmen,” while mass production is handled by general assembly lines. A reliable Chinese jewelry supplier will bridge this gap by using the same technical standards for both stages. When you work with a manufacturer, you should always ask about their transition process from sampling to mass production.

The Solution: Partner with a Chinese jewelry supplier that uses dedicated production lines for each client. At HonHo Jewelry, we maintain a defect rate below 0.5% by implementing a 100% quality inspection process. This means every single piece is checked by a human eye before it leaves the floor, ensuring the mass production matches the “Golden Sample” every time. This level of detail is what sets a premium manufacturer apart from the rest. A high-end Chinese jewelry supplier will never compromise on quality for the sake of speed.

Barrier 2: The Technical Black Box of Plating (PVD vs. Electroplating)

If your customers are complaining about jewelry turning their skin green or losing its gold color after a month, the barrier is technical. Most brands know they need “Gold Plating,” but few understand the science behind it. When you interview a potential partner, you must ask about their plating technology. A knowledgeable Chinese jewelry supplier will be able to explain the science behind their coating processes. A low-cost factory might use thin electroplating that wears off in weeks, while a high-quality Chinese jewelry supplier will invest in advanced PVD technology. Choosing a partner based on price alone can often lead to long-term brand damage.

The “Pre-cleaning” Secret

The biggest reason PVD (Physical Vapor Deposition) plating fails is not the plating itself—it is the cleaning. If even a microscopic layer of oil from a worker’s fingerprint remains on the metal, the gold will eventually peel.

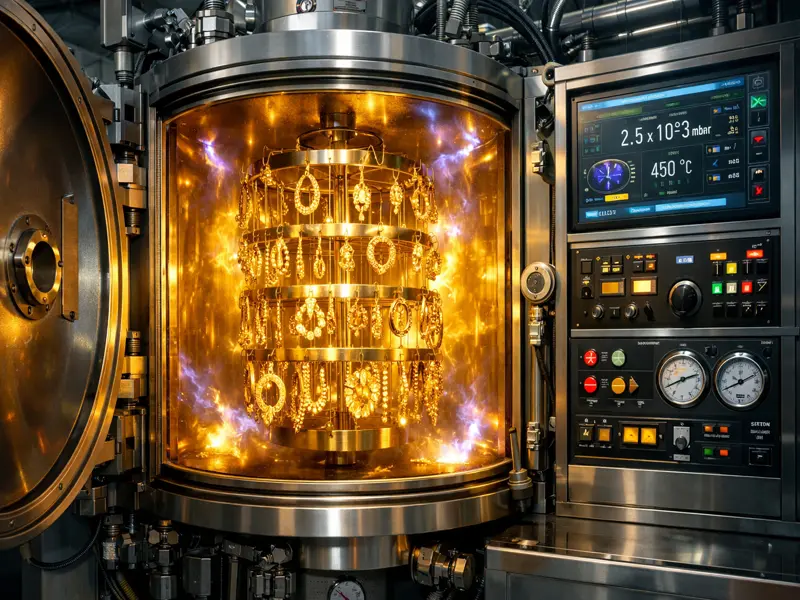

Alt: Technical PVD vacuum plating process for non-tarnish jewelry

Content Gap: The TiN Protective Layer

High-quality Chinese jewelry suppliers like HonHo use an advanced PVD plating process that includes a 0.5-micron Titanium Nitride (TiN) protective layer. This layer acts as a shield against moisture and oxidation.

While many factories outsource their plating—losing control over the process—HonHo operates an in-house vacuum plating plant. This allows us to offer a 24-month plating warranty, a rarity in the industry. This in-house capability is a hallmark of a superior manufacturer. A manufacturer with in-house plating can offer better quality control and faster turnaround times.

By controlling the environment, a manufacturer can guarantee the longevity of the finish, which is crucial for your brand’s reputation. Always verify if your partner has their own plating facility. A factory that outsources this critical step is one you should approach with caution.

Barrier 3: Communication & Design Misinterpretation

A 0.01mm difference in a CAD file might seem negligible, but in jewelry manufacturing, it is the difference between a stone that stays and a stone that falls out. Language barriers often exacerbate these technical misunderstandings.

From CAD to Reality

When working with your partner, ensure they have an in-house design team that understands US market aesthetics. Misinterpretation often happens when a factory tries to “simplify” a design for easier production without telling the client. A professional manufacturer will communicate any necessary changes before proceeding. This open dialogue is what makes a Chinese jewelry supplier a true partner. You want a partner that is proactive in their communication.

The Solution: Use 3D rendering and wax prototypes. Before any metal is cast, you should see a physical representation of your design. HonHo provides free CAD/3D rendering services, ensuring that what you see on your screen is exactly what you hold in your hand. This technical precision is why we are a preferred Chinese jewelry supplier for many global brands. A manufacturer that invests in design technology is one that values your creative vision. Your partner should be able to turn your most complex ideas into reality.

Alt: 3D CAD jewelry design being converted to a production mold

Barrier 4: Lead Times & Supply Chain Complexity

The jewelry industry is seasonal. If your Chinese jewelry supplier misses a Valentine’s Day or Christmas deadline, the loss is irrecoverable. Most delays happen because the factory is waiting on “accessories”—clasps, chains, or specific gemstones—from sub-suppliers. A smart manufacturer will have a robust local network to mitigate these risks. When you choose a Chinese jewelry supplier, you are also choosing their entire supply chain. A well-connected partner is essential for meeting tight deadlines.

The Dongguan Advantage

Dongguan is the heart of China’s jewelry manufacturing. Being located here gives a Chinese jewelry supplier like HonHo access to a network of over 5,000 specialized component manufacturers. This proximity reduces production time by up to 40%. When your partner has a “complete accessories supply chain” at their doorstep, your lead times become predictable. This geographical advantage is a key reason to work with a Chinese jewelry supplier in this region. A factory in Dongguan is at the center of the world’s jewelry innovation.

Barrier 5: Ethical Sourcing & Sustainability

In 2026, US consumers are more conscious than ever. A major barrier for modern brands is ensuring their partner follows ethical practices. Without proper certification, your brand is at risk. An ethical manufacturer is no longer a luxury; it is a requirement. Your customers want to know that their jewelry was made under fair conditions by a responsible Chinese jewelry supplier. A socially responsible manufacturer will always be transparent about their labor practices.

The Shield of Certification:

Always ask for factory audit reports. A reliable manufacturer will hold the following certifications:

- GRS (Global Recycled Standard): For sustainable materials.

- REACH: Ensuring products are lead-free, cadmium-free, and nickel-free.

- SMETA: For ethical labor practices.

HonHo Jewelry is a verified Chinese jewelry supplier that has passed all these inspections, providing you with the peace of mind that your brand’s reputation is safe. Working with a certified partner is the best way to future-proof your business. A manufacturer that prioritizes sustainability is one that is built for the future.

Alt: Eco-friendly and GRS certified jewelry materials

How to Audit Your Chinese Jewelry Supplier (2026 Checklist)

To truly overcome barriers, you must perform your due diligence. Here is a quick checklist for auditing a potential Chinese jewelry supplier. This checklist will help you separate a mediocre factory from a world-class one. Use this when vetting any potential partner:

- In-house Facilities: Do they have their own plating and polishing plants?

- Testing Labs: Do they have an in-house salt spray chamber to test durability?

- MOQ Flexibility: Do they support small-batch customization (e.g., 30 pieces) to help you test the market?

- Design Protection: Do they use secure servers and NDAs to protect your intellectual property?

- Communication: Do they offer 24-hour online support to bridge the time zone gap?

Alt: Detailed quality control inspection of sterling silver rings

Conclusion: Building a Partnership, Not Just a Transaction

Overcoming barriers with your Chinese jewelry supplier is about moving from a “vendor” mindset to a “partner” mindset. When you find a Chinese jewelry supplier that invests in in-house technology, maintains stringent quality control, and understands your brand’s ethical needs, the “barriers” become stepping stones to success. The right partner will grow with you, adapting to your needs as your brand scales. A scalable manufacturer is the backbone of any successful jewelry business.

At HonHo Jewelry, we specialize in solving these problems for our clients. With over 15 years of experience and a commitment to innovation, we are here to help your jewelry brand stand out in a competitive market. As your dedicated manufacturing partner, we take pride in your success. We believe that a supplier should be more than just a factory; it should be a growth partner.

Ready to scale your jewelry brand without the headaches?

Contact HonHo Jewelry today for a custom quote and let’s bring your vision to life. Partnering with the right Chinese jewelry supplier is the best decision you can make for your brand today. Don’t settle for anything less than the best partner for your business.

FAQs

1. How do I know if a Chinese jewelry supplier is reliable?

Look for certifications like ISO 9001, SMETA, and GRS. A reliable Chinese jewelry supplier will also be transparent about their manufacturing process and offer factory tours (physical or virtual).

2. What is the difference between PVD and electroplating?

PVD is a vacuum coating process that is much more durable and eco-friendly than traditional electroplating. It is the gold standard for “waterproof” and “non-tarnish” jewelry provided by a top Chinese jewelry supplier.

3. Why does my jewelry tarnish even if it’s “gold plated”?

Tarnishing often happens due to poor “pre-cleaning” before plating or a lack of a protective layer like Titanium Nitride (TiN). High-quality Chinese jewelry suppliers use in-house testing to prevent this.

4. What is the typical MOQ for a custom jewelry manufacturer in China?

While many large factories require 500+ pieces, flexible Chinese jewelry suppliers like HonHo offer MOQs as low as 30 pieces per style to support emerging brands.

5. How can I protect my jewelry designs from being copied?

Ensure your Chinese jewelry supplier signs a strict NDA and uses secure, encrypted servers for your CAD files. Restricted access to design rooms is also a key sign of a professional Chinese jewelry supplier.

6. How long does the sampling process take?

Typically, CAD designs take 1-2 days, and physical samples take 7-20 days. Rapid sample development is a key advantage of working with an experienced Chinese jewelry supplier.

7. Is it better to source from Dongguan or other regions?

Dongguan is widely considered the best region for high-end fashion jewelry due to its complete supply chain and concentration of skilled craftspeople working for a Chinese jewelry supplier.

8. How does salt spray testing help my brand?

A 48-hour salt spray test simulates approximately two years of intense wear. If your Chinese jewelry supplier passes this test, you can confidently market your products as “waterproof” and “long-lasting.”

Alt: In-house salt spray testing for waterproof jewelry durability

share this recipe:

Still hungry? Here’s more

How to Dodge Jewelry Sourcing Risks from China: Your 2026 Playbook

The allure of jewelry sourcing from China is undeniable. It’s a global hub of manufacturing,

Top 50 Jewelry Brands Worth to Buy 2026: The Definitive Investment & Style Encyclopedia

The global jewelry market in 2026 is a fascinating landscape where centuries-old heritage meets cutting-edge

Why Brass Jewelry Wholesale Fits Fashion Brands: The Strategic Guide for 2026

In the rapidly evolving landscape of the global fashion industry, the demand for affordable luxury

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.