The Unseen Hero: Why Earring Backings Define Quality Jewelry

Every jewelry brand owner knows the sinking feeling. A customer calls, distraught. They’ve lost one of their favorite earrings—a piece they cherished, a gift they loved. The culprit isn’t a dramatic theft but a silent failure: a tiny, overlooked component that gave way. This small piece, the earring backing, holds more than just the earring; it holds your customer’s trust and your brand’s reputation.

While customers are captivated by sparkling gemstones and intricate designs, seasoned jewelry professionals understand that the true measure of quality often lies in the details nobody sees. The choice of earring backings is not a minor manufacturing decision; it is a fundamental pillar of product integrity, customer satisfaction, and long-term brand value. For jewelry brands, designers, and retailers, overlooking the science and engineering of this component is a risk you can’t afford.

This guide is for you. We will go beyond a simple list of types and delve into the manufacturing perspective—exploring the materials, engineering, quality control, and customization that separate a flimsy, liability-prone finding from a secure, high-quality component that protects your customer’s investment and elevates your brand. Let’s uncover the vital importance of earring backings.

Beyond the Sparkle: The Critical Role of Earring Backings

For the end consumer, an earring is a single object. For a manufacturer, it’s an assembly of carefully engineered parts. The earring backing is arguably the most mechanically critical part of that assembly. Its performance directly impacts four key areas:

- Security: Its primary job is to prevent the loss of the earring. A failure here results in a direct monetary and sentimental loss for the customer, leading to dissatisfaction and potential damage to your brand’s image.

- Comfort: A poorly designed backing can pinch, poke, or cause allergic reactions. If an earring is uncomfortable, it won’t be worn, no matter how beautiful it is. This is especially true for customers with sensitive skin or multiple piercings.

- Durability: The backing must withstand repeated use, exposure to oils, cosmetics, and environmental factors without losing its grip or corroding. A backing that loosens or breaks after a few months reflects poorly on the overall quality of your jewelry.

- Presentation: The right backing ensures the earring sits correctly on the lobe. Heavy studs can droop with inadequate support, diminishing their beauty. A well-engineered backing provides the necessary lift and stability.

A Manufacturer’s Guide to Common Earring Backing Types

Understanding the mechanics of each backing type is the first step in selecting the right one for your designs. Here’s a breakdown from a B2B perspective, focusing on manufacturing and application suitability. Various earring backings offer different levels of security and comfort. (Image Source: AI-Generated)

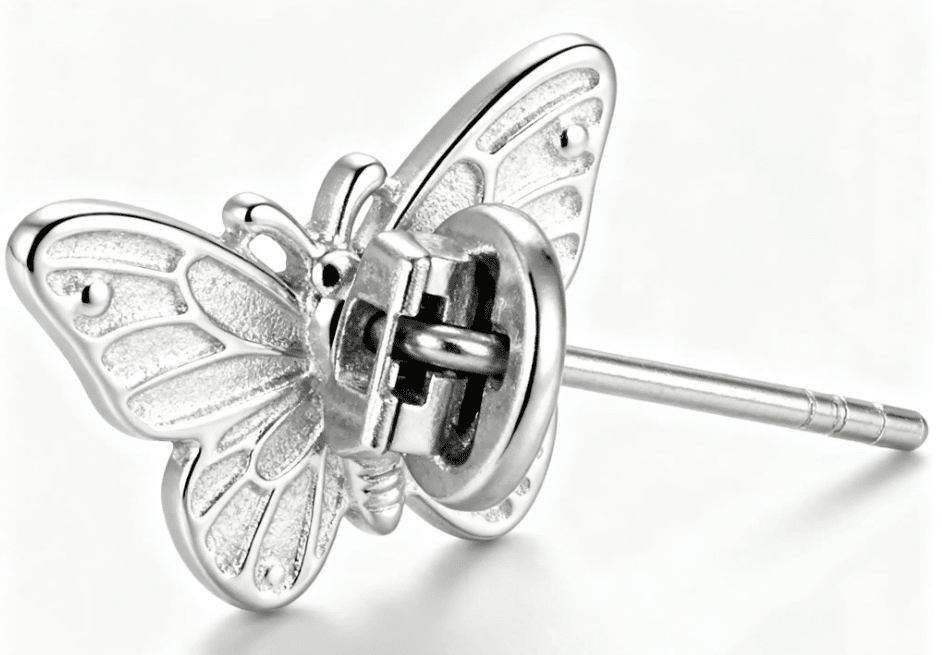

Friction Backs (Push/Butterfly Backs): The Ubiquitous Standard

This is the most common type of earring backing. It consists of a post with a small notch and a separate clutch (often shaped like a butterfly or scroll) that slides on. The clutch’s curled metal pieces create tension, gripping the notch to hold the earring in place.

- Best For: Lightweight studs, fashion jewelry, and pieces where cost-effectiveness and ease of use are priorities.

- Manufacturing Insight: The security of a friction back depends entirely on the clutch’s tension and the post’s notch placement. Over time, the metal in the clutch can lose its “springiness,” reducing grip. As a manufacturer, we ensure the alloy used has excellent fatigue resistance to maintain tension over thousands of uses.

Screw Backs: The Gold Standard for Security

These feature a threaded post and a backing that must be screwed on. This mechanical lock is far more secure than a friction grip, making it the preferred choice for high-value items like diamond or gemstone studs.

- Best For: High-value studs, children’s jewelry, and any piece where preventing loss is the absolute top priority.

- Manufacturing Insight: Precision is key. The threads on the post and in the backing must be perfectly matched to ensure a smooth, secure fit without cross-threading. The length of the post must also be carefully considered for comfort. We use precision machinery to create clean, consistent threads for all our custom-designed earrings.

La Pousette (Guardian) Backs: The Best of Both Worlds

A marvel of micro-engineering, La Pousette backs combine the security of a screw back with the ease of a push back. They feature a disc with two small tabs. When the tabs are squeezed, a spring-loaded mechanism releases its grip on the post. When released, it locks securely into a specially designed groove on the post.

- Best For: Luxury and fine jewelry where both high security and user convenience are desired.

- Manufacturing Insight: These are complex assemblies requiring high-precision components. The internal spring mechanism must be durable and corrosion-resistant. The post must have a perfectly positioned and shaped groove for the lock to engage reliably.

Lever, Latch, and Omega Backs: Integrated Solutions

These earring backings are not separate pieces but are built into the earring itself, common for hoops and dangles. A hinged post or wire clicks securely into a catch. Omega backs add a hinged loop for extra support on heavier earrings.

- Best For: Hoop earrings, drop earrings, and heavier statement pieces that need integrated support.

- Manufacturing Insight: The hinge is the critical component. It must be robust enough to withstand thousands of open-and-close cycles without loosening or breaking. The “click” of the closure should be firm and audible, signaling a secure lock to the wearer.

Flat Backs: The Modern Choice for Comfort

Popular for cartilage piercings and 24/7 wear, flat backs (or labret-style posts) consist of a post with a flat disc on one end. The decorative front is either pushed or screwed into the hollow post from the front. The flat disc sits flush against the back of the ear, preventing poking.

- Best For: Everyday studs, cartilage piercings, and customers who sleep in their earrings.

- Manufacturing Insight: The internal locking mechanism (either tension-fit for threadless or threaded) requires precise tolerances. The disc must be perfectly smooth with rounded edges to ensure maximum comfort against the skin.

The Science of Materials: Choosing the Right Metal for Your Earring Backings

The material of an earring backing is just as important as its design. It dictates durability, biocompatibility, and cost. As a manufacturer specializing in diverse metals, we understand the nuances of each option. The choice of material, from stainless steel to precious metals, impacts durability and biocompatibility. (Image Source: AliExpress)

Surgical Grade Stainless Steel (316L): The Durable Workhorse

316L stainless steel is an excellent choice for earring backings due to its superior strength, durability, and corrosion resistance. While it contains nickel, the alloy is stable, meaning the nickel is “locked” in and has a very low release rate, making it hypoallergenic for most people. It’s a cost-effective material that doesn’t compromise on performance, making it ideal for a wide range of jewelry. Our stainless steel earrings wholesale collection heavily utilizes this reliable material.

925 Sterling Silver: The Classic Choice

Sterling silver is a classic for a reason. It offers a beautiful finish and is generally well-tolerated. However, it is softer than stainless steel and can tarnish. For earring backings, especially friction backs, this softness means they can lose tension more quickly if not properly work-hardened during manufacturing. Rhodium plating is often applied to improve durability and prevent tarnish.

Copper and Its Alloys: Versatility and Warmth

Copper and its alloys, like brass, offer excellent malleability and a warm, unique color. They are often used as a base metal for plating with gold or silver. When used for earring backings, it’s crucial that the plating is thick and durable to prevent the base metal from contacting the skin, which can cause discoloration or reactions in sensitive individuals.

Titanium and Platinum: The Hypoallergenic Champions

For customers with extreme sensitivities, titanium and platinum are the ultimate choices. Both are highly inert and biocompatible. Titanium is incredibly lightweight and strong, often used for medical implants and meeting standards like ASTM F136. Platinum is a dense, precious metal that is naturally hypoallergenic. While these are premium-priced options, offering them can cater to a crucial segment of the market demanding the highest level of biocompatibility.

The Engineering of Quality: What Separates Good Earring Backings from Bad?

Two earring backings can look identical but perform vastly differently. The difference lies in the manufacturing details:

- Post Thickness and Hardness: A post that is too thin will bend easily. A post that is too soft will not provide a secure anchor. The diameter (gauge) and temper (hardness) of the wire used are critical specifications.

- Notch Profile: On a friction post, the notch shouldn’t be a sharp cut, which creates a weak point. It should be a smooth, rolled, or tumbled groove that allows the clutch to grip securely without compromising the post’s integrity.

- Clutch Tension: The “;springiness” of a butterfly clutch is a result of work-hardening the metal. A properly manufactured clutch is designed to withstand thousands of on-and-off cycles without losing its tension.

- Surface Finish: All surfaces, especially those that contact the skin, must be flawlessly polished. Burrs, sharp edges, or a rough finish can cause irritation and harbor bacteria.

Manufacturing Excellence: How We Test Earring Backings for Reliability

Reputable manufacturers don’t just hope their components are good; they prove it. At HonHo Jewelry, our quality assurance process involves rigorous testing that simulates real-world wear and tear. This commitment to data-driven quality is what gives our B2B clients confidence. Rigorous testing, including tensile and fatigue analysis, ensures the reliability of every earring backing. (Image Source: AI-Generated)

Tensile Strength Testing

We use specialized equipment to measure the force required to pull a backing off its post. This quantifies the security of the grip and ensures it meets standards far exceeding the gentle tugs of daily life. This is similar to tests defined by standards like ASTM F2999 for adult jewelry.

Fatigue and Cycle Testing

How many times can a customer put on and take off their earrings before the backing fails? We don’;t guess. We use automated machines to cycle earring backings on and off posts thousands of times, measuring the grip strength at intervals to determine the component’s functional lifespan.

Friction Coefficient Analysis

For friction backs, we analyze the coefficient of friction between the post and the clutch materials. This data helps us optimize the material pairing and surface finish for a grip that is secure but not so tight that it’s difficult for the user to operate.

Corrosion Resistance Testing

Earring backings are exposed to sweat, lotions, and perfumes. We subject our components to simulated body fluid (SBF) and salt spray tests to accelerate corrosion and ensure the materials and any platings hold up over time, preventing rust and degradation.

Hypoallergenic Compliance: Protecting Customers and Your Brand

The term “hypoallergenic” is not just a marketing buzzword; it’s a technical standard. For jewelry sold in many parts of the world, especially Europe, components must comply with the EU Nickel Directive, which limits the amount of nickel that can be released onto the skin. A responsible manufacturer must be able to provide documentation and test reports (like mill test certificates) to prove their materials and craftsmanship meet these stringent requirements. This protects your customers from painful allergic reactions and protects your brand from liability and reputational harm.

Beyond Function: Customization Options for Branded Earring Backings

For brands looking to elevate their presentation, the earring backing offers a unique branding opportunity. As a custom manufacturer, we can provide several options:

- Logo Stamping: A small, precisely stamped logo on the surface of a larger backing (like a jumbo friction back or a disc back) adds a subtle, premium touch.

- Custom Shapes: While butterfly backs are standard, clutches can be designed in custom shapes that reflect your brand’s aesthetic.

- Material and Finish Matching: Ensuring the backing perfectly matches the material and finish of the earring itself creates a cohesive, high-end look.

The True Cost of a Finding: Why Investing in Quality Earring Backings Pays Off

It can be tempting to cut costs on small findings like earring backings. A few cents saved per piece can add up over a large production run. However, this is a classic case of false economy. The cost of a single return, a bad review, or a lost customer due to a failed backing far outweighs the initial savings. Investing in a well-engineered, properly tested earring backing is an investment in customer loyalty, brand integrity, and long-term profitability.

Partner with HonHo Jewelry for Uncompromising Quality

The right earring backing is the silent guardian of your jewelry and your brand’s reputation. It requires a deep understanding of materials science, precision engineering, and rigorous quality control—principles that are at the core of everything we do at HonHo Jewelry.

Don’t let a tiny component become your biggest liability. Choose a manufacturing partner who treats every detail with the importance it deserves. Let us help you build jewelry that is not only beautiful but also secure, comfortable, and lasting.Request a Wholesale Inquiry Today

Frequently Asked Questions About Earring Backings

What is the most secure type of earring backing?

For stud earrings, screw backs and La Pousette (locking) backs are considered the most secure. They provide a mechanical lock that is highly resistant to being pulled or shaken loose, making them ideal for valuable jewelry.

Are stainless steel earring backings truly hypoallergenic?

Surgical-grade 316L stainless steel is considered hypoallergenic for the vast majority of people. While it contains nickel, the alloy is very stable and has a low nickel-release rate that complies with EU standards, preventing reactions in most individuals with sensitivities.

Why do my friction (push) backs become loose over time?

Friction backs rely on the tension of the metal scrolls to grip the post. With repeated use, the metal can experience fatigue and lose its “springiness,” leading to a looser grip. Choosing backings made from high-quality, fatigue-resistant alloys can significantly extend their secure lifespan.

Can you put a logo on an earring backing?

Yes, custom branding is possible. Logos can be precisely stamped or laser-engraved onto the surface of larger earring backings, such as jumbo friction backs or disc-style backs, adding a premium, branded touch to your jewelry.

What is the difference between a latch back and a lever back?

Both are integrated, hinged closures. A latch back is common on hoop earrings, where a post clicks into a “V” shaped catch. A lever back is common on dangle earrings and features a curved earwire that is closed by a hinged lever that snaps shut against the wire.

How does a manufacturer ensure the quality of earring backings?

Through rigorous quality control testing. This includes tensile strength tests (pull force), fatigue cycle tests (repeated use simulation), corrosion resistance tests (exposure to salt and moisture), and dimensional analysis to ensure all parts meet precise specifications.

What is the best earring backing for someone who sleeps in their earrings?

Flat back (labret-style) earrings are the best choice for 24/7 wear, including sleeping. The flat disc at the back sits flush against the skin and does not poke or cause discomfort when pressure is applied, unlike traditional post-and-clutch systems.

As a brand, why should I pay more for premium earring backings?

Investing in premium earring backings is an investment in your brand’s reputation. It reduces the risk of product returns, negative customer reviews, and the loss of valuable earrings. A secure, comfortable backing enhances the customer’s experience and builds trust in your brand’s quality.

share this recipe:

Still hungry? Here’s more

Choosing the Best Jewelry Stone Setting for Mass Production

Selecting the right jewelry stone setting is one of the most pivotal decisions for any

Best Jewelry Stone Setting for Mass Production | HonHo

Choosing the best jewelry stone setting Choosing the best jewelry stone setting is one of

Custom Engraved Jewelry Wholesale: Adding a Personal Touch

In today’s competitive retail market, standing out is everything. Consumers are no longer just buying

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.