The Importance of ISO 9001 Jewelry Certification for Brands: A Complete Guide to Quality and Trust

In the highly competitive and detail-oriented world of fine jewelry, a brand’s reputation is intrinsically linked to the quality and consistency of its products. Whether you operate as a niche boutique designer or manage a global retail chain, the promise of perfection is what defines your success. However, maintaining this promise across thousands of intricate pieces, diverse materials, and complex supply chains presents a monumental challenge. This is precisely where ISO 9001 Jewelry certification transcends a mere credential and becomes a fundamental pillar of operational excellence.

ISO 9001 is not simply a badge to be displayed; it is the globally recognized framework for a robust Quality Management System (QMS). For discerning jewelry brands, choosing an ISO 9001 certified manufacturer, such as Dongguan HonHo Jewelry, signifies more than just securing a supplier. It represents entering a strategic partnership founded on precision, documented transparency, and an unwavering commitment to continuous improvement.

This comprehensive guide will serve as your deep dive into why ISO 9001 is the undisputed gold standard for the modern jewelry industry. We will explore how it seamlessly bridges the gap between traditional craftsmanship and industrial efficiency, and why it is the essential, data-driven secret weapon for brands aiming to dominate the market and attract high-value inquiries in the coming years.

I. Understanding the ISO 9001 Framework in the Jewelry Context

At its core, ISO 9001:2015 is an international standard that outlines the criteria for a quality management system. When meticulously applied to the jewelry sector, its scope is exhaustive, covering every critical stage of the product lifecycle—from the initial Computer-Aided Design (CAD) and responsible raw material sourcing to the final, intricate polishing and secure packaging.

The fundamental difference between ISO 9001 and product-specific certifications is its focus on the entire process. It mandates that the manufacturing facility establishes a comprehensive, “fail-safe” system. This means that if a deviation or mistake occurs, the system is designed not only to identify and correct it immediately but also to implement preventative measures to ensure that the same issue never recurs. For a jewelry brand, this systematic approach translates directly into a dramatic reduction in product returns, warranty claims, and, most importantly, customer dissatisfaction.

The Seven Pillars of ISO 9001:2015 and Their Application

The standard is built upon seven core quality management principles, each having a profound impact on jewelry manufacturing:

| Principle | Application in Jewelry Manufacturing | Strategic Benefit to Your Brand |

|---|---|---|

| 1. Customer Focus | Aligning all production processes with the brand’s specific design specifications and market needs. | Products that consistently meet or exceed your exact vision and customer expectations. |

| 2. Leadership | Management’s active commitment to establishing and maintaining quality policies and objectives. | Ensures a reliable, long-term manufacturing partnership with consistent standards. |

| 3. Engagement of People | Training and empowering all staff, from CAD designers to stone setters, in quality procedures. | Higher skill levels, reduced human error, and a culture of excellence. |

| 4. Process Approach | Standardizing and documenting every step: casting, setting, polishing, and plating. | Guarantees consistent quality, finish, and durability across all production batches. |

| 5. Improvement | Implementing a cycle of continuous review and enhancement of the QMS. | Access to the latest jewelry manufacturing innovations and process efficiencies. |

| 6. Evidence-based Decision Making | Using data (e.g., defect rates, material usage) to drive process optimization. | Lower manufacturing costs, faster turnaround times, and verifiable quality claims. |

| 7. Relationship Management | Establishing quality criteria for all external providers, including raw material suppliers. | Ensures ethical sourcing and consistent material quality from the supply chain. |

II. Bridging the Content Gap: Technical Excellence in ISO 9001 Jewelry Manufacturing

In the digital landscape, simply mentioning “quality control” is no longer enough to attract high-intent B2B buyers. The true Content Gap lies in providing the technical depth that demonstrates genuine expertise and authority (the ‘E’ and ‘A’ in Google’s EEAT framework).

While competitors offer vague promises, an ISO 9001 QMS provides the detailed, auditable procedures that define true manufacturing mastery. We will now explore the specific, technical quality control (QC) steps that an ISO-certified facility mandates, often overlooked by non-certified manufacturers.

The ISO 9001 Mandate: Precision at Every Stage

A. Raw Material and Pre-Production QC (Clause 8.4)

The QMS begins long before production. ISO 9001 requires strict control over externally provided processes, products, and services.

- Metal Purity Analysis: Every batch of precious metal (gold, silver, platinum) must undergo regular, documented testing, typically using X-ray Fluorescence (XRF) technology. This verifies that 18K gold is precisely 75% pure, protecting your brand from legal risks and ensuring product integrity.

- Gemstone Inspection: Incoming stones are checked for size, cut, color, clarity, and most critically, any internal flaws that could lead to breakage during the setting process. This is a crucial step in risk mitigation.

B. Casting and Fabrication QC (Clause 8.5)

The casting process is a major source of defects. ISO 9001 mandates specific checks to ensure structural integrity.

- Porosity Check: After casting, pieces are examined under high-resolution magnification or even X-ray to ensure the metal is dense and free of tiny air bubbles (porosity). Porosity is a structural weakness that can cause the jewelry to break or crack later.

- Shank Thickness Verification: For rings, digital calipers are used to verify that the shank (the band) meets the exact millimeter specifications defined in the CAD file. This ensures durability and consistent sizing.

C. Stone Setting and Finishing QC (Clause 8.5)

This is where craftsmanship meets the QMS.

- Loose Stone Testing: A rigorous, documented “shake and tap” test is performed on every piece after setting to ensure that every diamond or gemstone is securely held. This procedure significantly reduces the risk of stone loss, a major source of customer complaints.

- Plating Thickness Measurement: For rhodium or gold plating, the thickness (measured in microns) must be consistently verified using specialized equipment. Inconsistent plating leads to premature tarnishing and wear. An ISO-certified process ensures a durable, long-lasting finish.

D. The Role of Modern Technology

ISO 9001 encourages the adoption of new technologies for process improvement. Modern ISO-certified facilities integrate advanced tools:

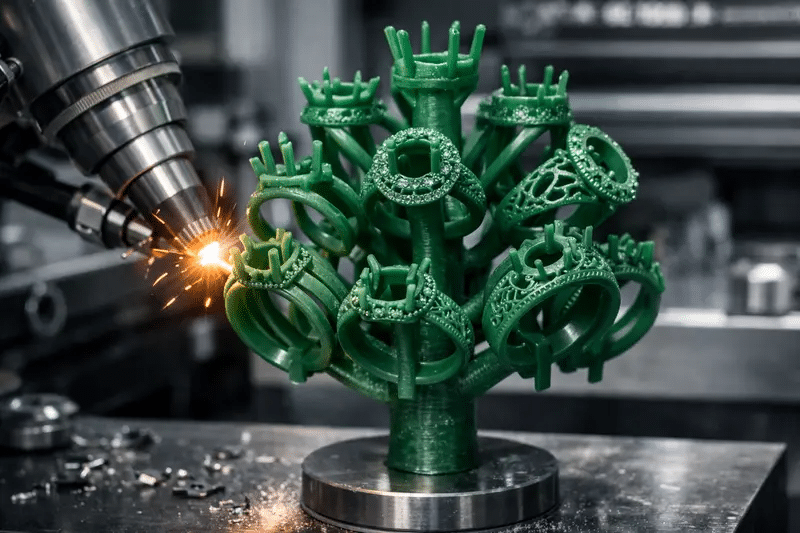

- 3D Printing/CAD: The QMS ensures that the digital design files are version-controlled and that the 3D printed wax models are checked for dimensional accuracy before casting.

- Laser Welding: Procedures for laser welding are documented and standardized to ensure strong, invisible joins, eliminating the weaknesses associated with traditional soldering.

III. Strategic Benefits: Why ISO 9001 Attracts Inquiries

The commitment to ISO 9001 Jewelry standards is a powerful marketing tool that directly addresses the concerns of B2B buyers and end consumers alike.

1. Building Unshakable Consumer Trust (EEAT – Trustworthiness)

In the e-commerce era, consumers are increasingly skeptical. They cannot physically inspect the jewelry before purchase. When a brand can confidently state that its products are manufactured in an ISO 9001 certified facility, it provides a level of verifiable assurance that “un-certified” competitors simply cannot match. It signals that your brand prioritizes professional, auditable standards over unproven claims of “handcrafted quality.”

2. Streamlining the Global Supply Chain (EEAT – Authority)

The global jewelry supply chain is notoriously complex, involving multiple international vendors. ISO 9001 mandates strict Supply Chain Transparency (Clause 8.4). This means every gram of precious metal and every sourced stone is tracked, documented, and traceable. For brands committed to meeting modern ESG (Environmental, Social, and Governance) goals, this documentation is invaluable. It ensures that your manufacturer is not just a producer, but a manager of a transparent and ethical pipeline.

“The ISO 9001 framework provides the necessary structure for a jewelry brand to demonstrate not only product quality but also the ethical integrity of its sourcing, which is increasingly demanded by the modern luxury consumer.”

3. Risk-Based Thinking and Cost Reduction

The ISO 9001:2015 revision introduced the concept of “Risk-Based Thinking.” In the jewelry industry, risks are numerous: metal price volatility, stone loss during setting, and international shipping delays. An ISO-certified partner has documented contingency plans for these risks. By proactively optimizing resource utilization and drastically reducing waste (re-work), these manufacturers can often offer more competitive pricing and faster delivery times without ever compromising on quality. This is a key advantage for brands looking to scale their custom design services.

IV. ISO 9001 vs. Other Key Industry Standards

Many brands correctly prioritize other certifications, leading to the question: “Do I need ISO 9001 if my supplier is already RJC (Responsible Jewellery Council) certified?”

The answer is a resounding Yes. While the RJC focuses heavily on ethics, sustainability, and human rights, ISO 9001 focuses on operational excellence and quality consistency. They are complementary, not interchangeable. Think of RJC as addressing the “heart” (ethics) of the business and ISO 9001 as managing the “brain” (efficiency and quality). Together, they create a brand that is both ethically sound and flawlessly efficient.

| Feature | ISO 9001 (QMS) | RJC Certification |

|---|---|---|

| Primary Focus | Quality Management, Efficiency, and Consistency | Ethical, Social, and Environmental Responsibility |

| Audit Scope | Internal Processes, Documentation, and Systems | Human Rights, Labor Practices, and Responsible Sourcing |

| Customer Impact | Product Reliability, Durability, and Consistency | Brand Values, Ethics, and Sustainability Claims |

| Relevant Clause | Clause 8.5 (Production Provision) | Supply Chain Due Diligence |

For brands focusing on high-volume production, ISO 9001 is the most critical factor for ensuring every piece is identical.

V. Implementing ISO 9001 Standards in Your Brand’s Strategy

To leverage the power of ISO 9001, your brand must actively demand and verify compliance from its manufacturing partners. This due diligence is part of your own EEAT commitment to your customers.

The Supplier Vetting Checklist

- Certification Validity: Always request the supplier’s current ISO 9001:2015 certificate. Verify its accreditation body and check the expiration date.

- Audit Reports: A transparent partner should be willing to share summaries of their latest internal and external surveillance audits. Look for evidence of Corrective Actions (CARs) taken (Clause 10.2).

- QC Documentation: Request to review their “Standard Operating Procedures” (SOPs) for critical processes like stone setting, metal casting, and plating. This is a direct insight into their QMS.

- Continuous Improvement Record: Ask for examples of technical upgrades or process refinements they have implemented in the last 12 months, demonstrating their commitment to Clause 10.3.

By partnering with an ISO 9001 certified manufacturer like HonHo Jewelry, you are not just outsourcing production; you are integrating a world-class quality system into your brand’s DNA. We ensure that our clients receive nothing less than perfection for their OEM/ODM projects

VI. Frequently Asked Questions (FAQs)

1. Is ISO 9001 mandatory for jewelry brands?

No, it is not legally mandatory in most jurisdictions, but it is a powerful “market-driven” necessity. Major high-end retailers, department stores, and large e-commerce platforms increasingly require their suppliers to hold ISO 9001 or equivalent certifications to ensure consistent quality and reduce supply chain risk.

2. How does ISO 9001 help in reducing jewelry manufacturing costs?

ISO 9001’s focus on the Process Approach (Clause 4.4) and Improvement (Clause 10) directly reduces “re-work” (fixing mistakes) and scrap material. By optimizing material usage and minimizing defects, which can be as high as 30% in non-certified factories, the overall cost of quality is significantly lowered, leading to better pricing for your brand.

3. Can a small jewelry brand benefit from demanding ISO 9001 compliance?

Absolutely. In fact, small and emerging brands benefit the most. By choosing an ISO-certified partner, they can immediately compete with much larger companies by offering the same level of quality assurance, professional documentation, and risk mitigation. This allows them to focus on marketing and sales [Internal Link 4: https://www.honhojewelry.com/] rather than constant quality checks.

4. What is the difference between ISO 9001 and ISO 14001 in jewelry?

ISO 9001 focuses on Quality Management (how well you make the product), while ISO 14001 focuses on Environmental Management (how sustainably you operate). Many top-tier manufacturers hold both to ensure they are both high-quality and environmentally responsible.

5. Does ISO 9001 guarantee that stones won’t fall out?

While no system can guarantee 100% perfection, ISO 9001 mandates a documented “Loose Stone Check” process (part of Clause 8.5) that significantly reduces the risk of stones falling out compared to non-certified factories. The QMS ensures that the setting process is standardized and verified.

6. How often are ISO 9001 jewelry factories audited?

Factories typically undergo a full re-certification audit every three years. In the intervening years, they must pass annual surveillance audits to ensure they are still actively following and maintaining the quality management protocols.

7. Does ISO 9001 cover ethical sourcing?

ISO 9001 primarily covers quality processes. However, the “Purchasing” clause (Clause 8.4) requires manufacturers to evaluate and monitor their external suppliers based on their ability to provide conforming products and services. This requirement indirectly supports better sourcing practices and is a foundational element for more specific ethical standards like RJC.

8. Why should I choose an ISO 9001 certified manufacturer in China?

China is a global hub for advanced jewelry technology and manufacturing scale. An ISO 9001 certified manufacturer in China, like HonHo Jewelry, combines cutting-edge technology (such as 3D printing and advanced casting) with rigorous international quality standards, offering the best combination of value, scale, and quality assurance for global brands seeking reliable production partners.

9. What is the biggest risk of using a non-ISO 9001 certified supplier?

The biggest risk is inconsistency. Without a documented QMS, quality relies on individual skill rather than a repeatable system. This leads to unpredictable defect rates, varying product finishes, and a lack of traceability when problems occur, ultimately damaging your brand’s reputation.

10. How does ISO 9001 relate to the Plan-Do-Check-Act (PDCA) cycle?

The entire ISO 9001 QMS is structured around the PDCA cycle: Plan (establish objectives and processes – Clauses 4, 5, 6), Do (implement the processes – Clause 7, 8), Check (monitor and measure processes – Clause 9), and Act (take actions to improve performance – Clause 10). This ensures the system is always evolving and improving.

Conclusion: The Future of Jewelry is Certified and Transparent

The jewelry industry is rapidly moving away from relying on anecdotal “trust me” claims and toward verifiable “show me” evidence. Brands that can substantiate their quality claims through the rigorous, internationally recognized framework of ISO 9001 Jewelry standards are the ones that will capture the trust of the modern, informed B2B buyer and end consumer.

By choosing a certified manufacturing partner, you are not merely purchasing a product; you are making a strategic investment in the longevity, scalability, and impeccable reputation of your brand.

Ready to elevate your jewelry brand with certified quality and unparalleled manufacturing precision? Contact HonHo Jewelry today to discuss your next collection and experience the ISO 9001 difference.

References

ISO.org – ISO 9001 Quality Management

International Gemological Institute (IGI) – Metal QC Process

Responsible Jewellery Council (RJC) – Certification

GIA – Gemological Institute of America

ISO 14001 Environmental Management

share this recipe:

Still hungry? Here’s more

Top 50 Jewelry Brands Worth to Buy 2026: The Definitive Investment & Style Encyclopedia

The global jewelry market in 2026 is a fascinating landscape where centuries-old heritage meets cutting-edge

Why Brass Jewelry Wholesale Fits Fashion Brands: The Strategic Guide for 2026

In the rapidly evolving landscape of the global fashion industry, the demand for affordable luxury

Enamel Jewelry Wholesale: Adding Color to Your Brand’s Collections

In the ever-evolving world of fashion, color has become the ultimate tool for self-expression. For

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.