How to Find a Reliable Custom Jewelry Manufacturer in China (2026 Guide)

The Ultimate Guide to Partnering with a Custom Jewelry Manufacturer in China

In the booming world of jewelry, turning a unique design idea into a tangible, high-quality product requires the right partner. For decades, China has been the global powerhouse for jewelry manufacturing, offering an unmatched combination of advanced technology, skilled craftsmanship, and cost-efficiency. However, the sheer size of the market presents a challenge: How do you find a truly reliable Custom Jewelry Manufacturer that can deliver on quality, ethics, and innovation?

This guide cuts through the noise. Drawing on deep industry knowledge and technical insights often hidden from the public, we will provide you with an expert, step-by-step framework to vet potential partners, understand the technical process, and secure a successful, long-term manufacturing relationship.

Why China Remains the Global Hub for Custom Jewelry

The decision to manufacture in China is often driven by economics, but the real advantage lies in the ecosystem.

| Factor | Benefit for Custom Jewelry Brands |

|---|---|

| Advanced Technology | Access to state-of-the-art 3D printing, laser welding, and PVD electroplating equipment that is often too costly for smaller, local manufacturers. |

| Skilled Labor Pool | Decades of experience in complex processes like micro-pave setting and investment casting, particularly in specialized regions. |

| Scalability | The ability to handle low Minimum Order Quantities (MOQs) for startups and seamlessly scale up to mass production for established brands. |

| Supply Chain | A mature, integrated supply chain for raw materials (metals, stones) that ensures competitive pricing and faster turnaround times. |

The Crucial First Step: Distinguishing a Factory from a Trading Company

This is the single most important piece of advice. Many companies on B2B platforms are trading companies (middlemen) who simply outsource your order. While not all are bad, a direct factory offers better pricing, quality control, and communication.

The “Real Factory” Verification Checklist

To ensure you are dealing with a genuine Custom Jewelry Manufacturer, use this three-point verification system:

- Business License Audit: Ask for a copy of their Chinese business license. A real factory will have “Manufacturing” (制造 – zhì zào) or “Processing” (加工 – jiā gōng) explicitly listed in their business scope. A trading company will only list “Sales” (销售 – xiāo shòu) or “Trading” (贸易 – mào yì).

- Geographic Cluster Logic: China’s jewelry industry is highly specialized. Knowing the location can tell you a lot about their expertise:

- Panyu, Guangzhou: The undisputed center for high-end fine jewelry (gold, silver, diamonds, high-quality gemstones). Factories here are known for exceptional craftsmanship and strict quality control.

- Shenzhen: Strong in fashion jewelry, stainless steel, and technology-driven manufacturing.

- Yiwu: Primarily focused on low-cost, high-volume fashion accessories.

- If your manufacturer is in Panyu, it’s a strong indicator of fine jewelry expertise.

- The Technical Interview: A trading company will struggle to answer detailed technical questions. A factory manager will speak fluently about their machinery and processes. Ask about:

- Their specific 3D printing technology (SLA, DLP, or DOD).

- The type of vacuum casting machine they use.

- Their internal quality control process (e.g., three-stage inspection: wax model, raw casting, finished product).

ALT: Magnifying glass over a Chinese business license showing Manufacturing scope

The Technical Edge: Understanding the Custom Manufacturing Process

To truly evaluate a manufacturer, you must understand the technical journey of your custom piece. This knowledge is your shield against poor quality and inflated costs.

Phase 1: Precision Modeling (CAD & 3D Printing)

The days of hand-carving every wax model are largely over, replaced by digital precision.

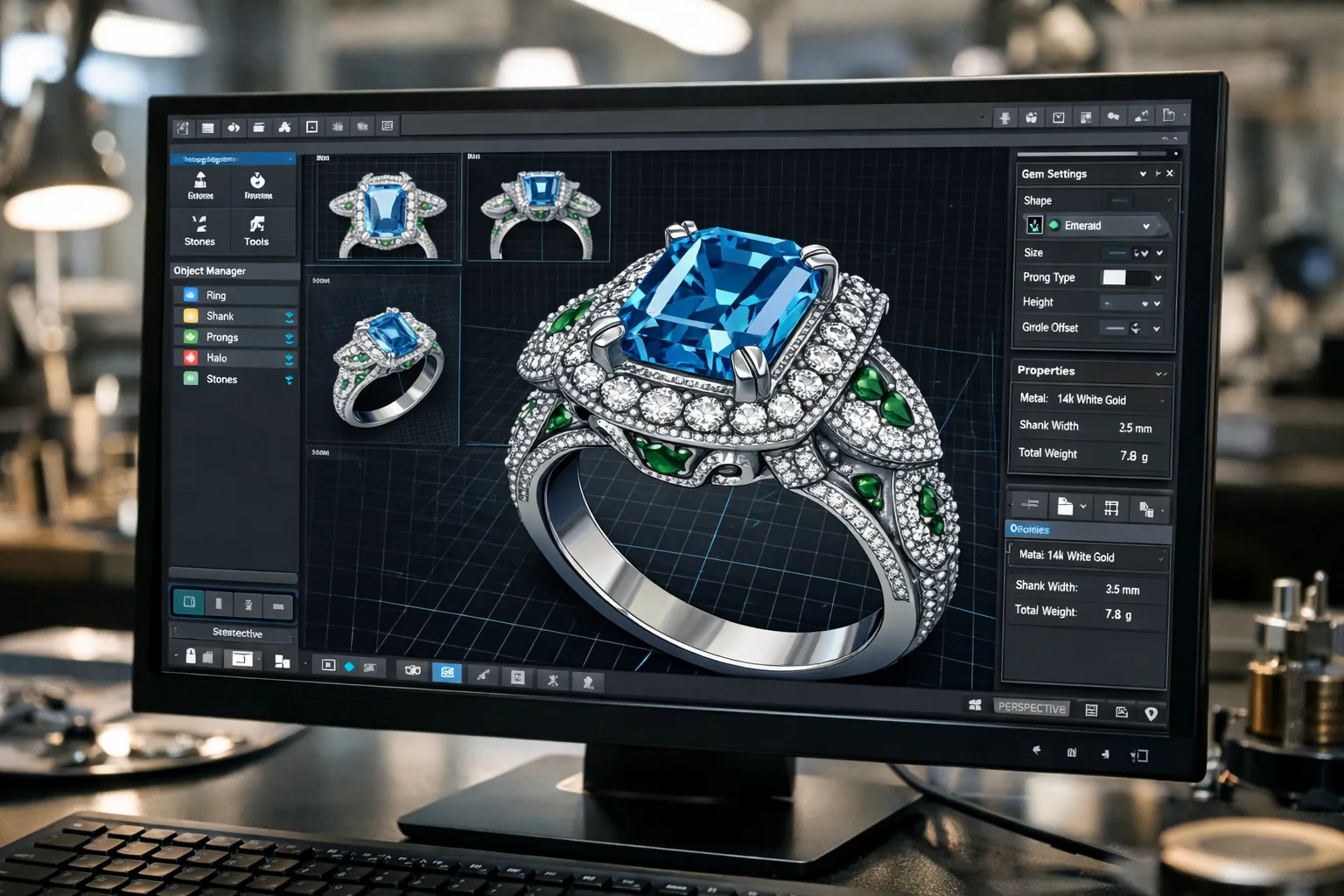

- CAD Design: Your manufacturer should use professional software (like Rhino or Matrix) to create a detailed 3D model. This is where all measurements, stone sizes, and tolerances are set.

- 3D Printing Technology: The quality of the final casting depends heavily on the 3D printed wax pattern. There are three main types:

- SLA/DLP (Resin): Cost-effective and fast. However, some resins can leave ash residue during the burnout process, leading to tiny imperfections (porosity) in the final metal casting.

- DOD (Drop-on-Demand – Wax): This is the superior method for high-end custom jewelry. DOD printers use a wax-like material that burns out completely, leaving virtually zero ash. This results in a cleaner, smoother casting that requires less manual finishing, which is a key indicator of a high-quality manufacturer.

ALT: 3D model of a custom ring design on a computer screen

Phase 2: Investment Casting – The Heart of Production

Investment casting, often called the “lost-wax” process, is a complex, multi-step procedure that transforms the wax pattern into a metal piece.

| Step | Description | Quality Indicator to Watch For |

|---|---|---|

| Casting Tree Assembly | Multiple wax patterns are attached to a central wax sprue (the “tree”). This must be done strategically to ensure even metal flow. | Poor assembly leads to incomplete or porous castings. |

| Shell Building | The tree is encased in a ceramic slurry, which hardens into a mold. | The quality of the slurry and drying process prevents cracks and surface defects. |

| Burnout | The mold is heated in a furnace, melting the wax (hence “lost-wax”). The wax must burn out completely. | Incomplete burnout (ash residue) causes porosity and rough surfaces. |

| Pouring | Molten metal (gold, silver, brass) is vacuum-poured into the ceramic mold. | Use of a vacuum casting machine ensures the metal fills every intricate detail without air bubbles. [3] |

Phase 3: Finishing and Electroplating

After casting, the raw metal piece is separated from the tree and moves to the finishing stage.

- Polishing: This is a blend of machine and manual work. High-quality manufacturers use multi-stage polishing to achieve a mirror finish without losing detail.

- Stone Setting: Expertise is critical here. Look for manufacturers skilled in micro-pave, channel, or bezel setting, depending on your design.

- Electroplating (The Final Shine): This is crucial for silver and brass jewelry. PVD (Physical Vapor Deposition) is the modern, superior method for gold plating. It is significantly more durable and long-lasting than traditional water plating, which is a major factor in customer satisfaction and product longevity.

Essential Criteria for Trustworthiness (EEAT & Ethics)

A reliable manufacturer is not just technically proficient; they are also ethically sound. Your brand reputation depends on their practices.

1. Ethical Sourcing and Compliance

In today’s market, customers demand transparency. Your manufacturer must adhere to international ethical standards.

- RJC Compliance: The Responsible Jewellery Council 1 is a global standard for ethical, social, and environmental practices. While not every factory is certified, a commitment to RJC principles is a huge green flag.

- Kimberley Process: Essential for diamond sourcing, ensuring that stones are conflict-free.

- Material Testing: Demand third-party material test reports (SGS or TUV) for all metals and plating to confirm they are lead-free, nickel-free, and meet international standards.

2. Communication and Intellectual Property (IP)

- Clear Communication: The best factories have dedicated English-speaking project managers who can discuss technical details, not just pricing.

- NDA Protection: Always sign a Non-Disclosure Agreement (NDA) before sharing your designs. A trustworthy manufacturer will respect your intellectual property and have a standard NDA ready.

Avoiding the Pitfalls: Common Red Flags

Be wary of these signs, which often indicate a manufacturer is cutting corners:

| Red Flag | Implication | Expert Advice |

|---|---|---|

| “Too Good to Be True” Pricing | They are using inferior materials (e.g., low-grade brass instead of silver), cheap plating (water plating), or skipping crucial quality control steps. | Expect to pay a fair price for quality. If a quote is 30% lower than others, investigate why. |

| Vague Technical Answers | They cannot explain the difference between SLA and DOD printing, or they avoid questions about their casting process. | This is a sign of a trading company or a factory with outdated technology. |

| No Factory Photos/Video | They refuse a live video tour of their workshop floor, only showing a polished office. | Demand a live video call where they show you their casting room and polishing stations. |

| Extremely Low MOQ for Fine Jewelry | While low MOQs exist, extremely low numbers (e.g., 10 pieces for a complex silver design) often mean they are batching your order with others, which compromises quality control. | A reliable factory will have a reasonable, transparent MOQ based on the complexity of the design. |

Your Partner in Custom Jewelry Manufacturing: Dongguan HonHo Jewelry

At Dongguan HonHo Jewelry, we understand that finding the right partner is about more than just a transaction—it’s about trust, quality, and shared expertise. Located in the heart of the manufacturing hub, we specialize in high-quality custom jewelry, adhering to the highest standards of technical precision and ethical practice.

We utilize advanced DOD 3D printing for flawless wax patterns and employ multi-stage quality control to ensure every piece meets the Panyu standard of excellence. Our team is dedicated to helping you scale your brand with transparent communication and superior craftsmanship.

If you are ready to transform your designs into market-ready jewelry with a reliable, expert partner, we invite you to start your inquiry today.

ALT: High-quality finished custom necklace with micro-pave setting

Frequently Asked Questions (FAQs)

What is the typical MOQ for custom jewelry in China?

The MOQ (Minimum Order Quantity) varies significantly based on the material and complexity. For high-quality custom silver jewelry, a reliable factory typically requires an MOQ between 50 to 100 pieces per design. For complex fine gold jewelry, the MOQ may be lower (e.g., 30 pieces), while for simple fashion jewelry, it can be 200+ pieces.

How long does the custom jewelry sampling process take?

From the final CAD approval, the sampling process usually takes 3 to 4 weeks. This includes 3D printing the wax model, casting, finishing, and quality control. Mass production typically takes an additional 4-6 weeks after sample approval.

Can I protect my designs with an NDA?

Absolutely. You must protect your intellectual property. A reputable Chinese manufacturer will readily sign a Non-Disclosure Agreement (NDA) to ensure your designs remain confidential. This is a standard business practice and a sign of a trustworthy partner.

What materials are best for high-quality custom jewelry?

For fine jewelry, Sterling Silver (925) and Gold (10K, 14K, 18K) are the standards. For durable fashion jewelry, Stainless Steel is an excellent choice. Avoid low-grade alloys that contain high levels of nickel or lead, as these can cause skin irritation and fail international safety tests.

How do I pay a Chinese jewelry manufacturer safely?

The safest methods are Bank Wire Transfer (T/T) or using a secure platform like Alibaba Trade Assurance. Never use Western Union or other unsecured methods. A standard payment term is a 30% deposit to start production and the 70% balance upon completion and final quality inspection (before shipping).

Conclusion: Your Path to a Successful Partnership

Finding a reliable Custom Jewelry Manufacturer in China is a strategic process, not a simple search. By focusing on technical expertise (understanding 3D printing and casting), verifying their status (factory vs. trading company), and demanding ethical compliance (RJC, material testing), you elevate your brand and secure a partner capable of delivering the quality your customers expect.

Start your journey with confidence. The right manufacturer is the foundation of your jewelry brand’s success.

References

[1] Responsible Jewellery Council (RJC) – The global standard for ethical, social and environmental practices in the jewelry industry.

[2] U.S. Customs and Border Protection – Information on HS Codes for Jewelry Imports.

[3] Protolabs Blog – 3D Printing for Jewellery Applications.

[4] YouTube Channel – Jewelry Manufacturing Process – Technical insights on jewelry casting and 3D printing.

share this recipe:

Still hungry? Here’s more

How to Dodge Jewelry Sourcing Risks from China: Your 2026 Playbook

The allure of jewelry sourcing from China is undeniable. It’s a global hub of manufacturing,

Top 50 Jewelry Brands Worth to Buy 2026: The Definitive Investment & Style Encyclopedia

The global jewelry market in 2026 is a fascinating landscape where centuries-old heritage meets cutting-edge

Why Brass Jewelry Wholesale Fits Fashion Brands: The Strategic Guide for 2026

In the rapidly evolving landscape of the global fashion industry, the demand for affordable luxury

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.