Small Batch Jewelry Manufacturing: Why Low MOQ is the Future for Modern Brands

The jewelry industry is undergoing a seismic shift. For decades, the path to success for a jewelry brand was paved with massive orders, high minimum order quantities (MOQs), and significant upfront capital. However, as we move into 2026, the landscape has changed. Today, agility, sustainability, and market responsiveness are the new currencies of success. This is why small batch jewelry manufacturing is no longer just an option for startups—it is the strategic future for brands of all sizes.

At Dongguan HonHo Jewelry, we have witnessed firsthand how the “Low MOQ” model empowers designers to innovate without the fear of dead stock. In this comprehensive guide, we will delve into the technical, financial, and strategic reasons why small batch jewelry production is the ultimate competitive advantage in the modern market.

I. What Exactly is Small Batch Jewelry Manufacturing?

In the traditional sense, jewelry manufacturing was a game of scale. Factories would often demand MOQs of 300 to 500 pieces per style to justify the setup costs of molds and casting trees. Small batch jewelry manufacturing flips this script. It refers to the production of limited quantities—typically ranging from 5 to 50 pieces per design—while maintaining the same professional standards as mass production.

This model is made possible by advancements in technology, such as high-resolution 3D wax printing and precision casting machines that can handle smaller “flasks” efficiently. For a brand, this means you can launch a “capsule collection” or a “micro-drop” with minimal financial exposure.

The Shift from Mass Production to Micro-Collections

| Feature | Traditional Mass Production | Small Batch Jewelry Production |

|---|---|---|

| Minimum Order (MOQ) | 300+ pieces per style | 5 – 50 pieces per style |

| Upfront Investment | High ($10,000+) | Low ($500 – $2,000) |

| Market Testing | Slow and risky | Fast and agile |

| Inventory Risk | High (Potential dead stock) | Minimal (Produce on demand) |

| Customization | Limited | Highly flexible |

II. Why Low MOQ is the Future: The Strategic Advantages

The rise of direct-to-consumer (DTC) brands and social media “drop culture” has made small batch jewelry the preferred choice for the modern entrepreneur. Here is why this model is winning:

1. Financial Agility and Cash Flow Management

Cash flow is the lifeblood of any business. High MOQs freeze your capital in unsold inventory. By opting for small batch jewelry runs, you can allocate your budget more effectively—spending more on marketing and brand building rather than storage and insurance for excess stock. This “lean” approach allows you to reinvest profits from one small batch directly into the next design.

2. Rapid Market Testing and Iteration

In the fast-paced world of TikTok and Instagram trends, a design that is “hot” today might be forgotten in three months. Small batch jewelry manufacturing allows you to test a concept with 20 pieces. If it sells out in 48 hours, you scale up. If it doesn’t resonate, you haven’t lost thousands of dollars. This ability to iterate based on real-time customer feedback is a superpower for niche brands.

3. The Ultimate Sustainability Move

Sustainability is no longer a buzzword; it is a consumer requirement. The most unsustainable part of the jewelry industry is overproduction. Millions of pieces of jewelry end up in landfills or are melted down every year because they didn’t sell. Small batch jewelry production is inherently “slow fashion.” It reduces waste, minimizes the carbon footprint of shipping massive bulk orders, and ensures that every piece created has a high probability of being cherished by a customer.

III. Technical Innovations Powering Small Batch Efficiency

One of the biggest myths in the industry is that small batch jewelry means lower quality or higher per-unit costs. Thanks to technical breakthroughs, this is no longer true.

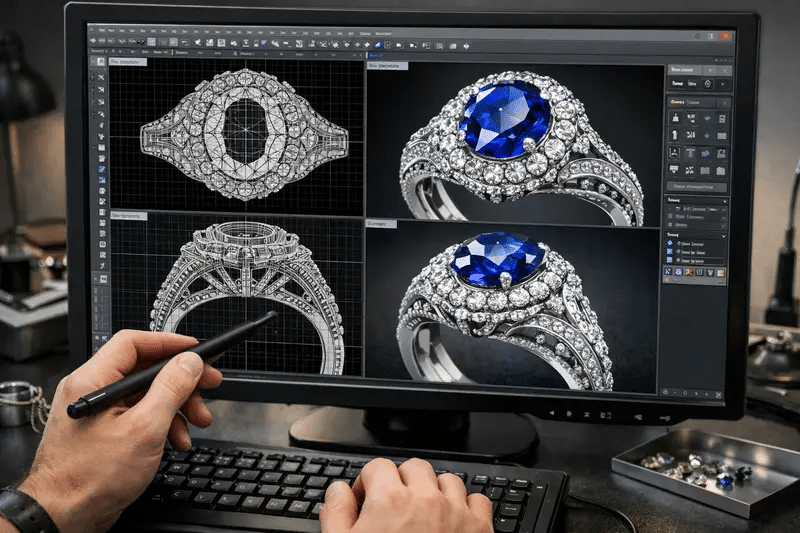

1. Precision 3D Wax Printing

In the past, creating a mold for a single ring was expensive. Today, high-speed 3D printers can produce dozens of different wax models in a single run. This allows a manufacturer like HonHo Jewelry to combine multiple small orders into one casting cycle, significantly reducing the “setup cost” for each brand.

2. Zero-Porosity Casting Technology

Advanced vacuum pressure casting machines are now designed to handle smaller batches with extreme precision. Technologies like “Electric Hammering” ensure that even a small run of 10 rings has the same density and smoothness as a run of 1,000. This eliminates the “porosity” issues that used to plague small-scale casting.

3. Automated Finishing for Small Runs

While the assembly might be manual, finishing processes like magnetic polishing and ultrasonic cleaning are now optimized for small batches. This ensures a consistent, mirror-like finish across every piece in your small batch jewelry collection.

IV. How to Choose a Reliable Small Batch Jewelry Manufacturer

Not all manufacturers who claim to offer “Low MOQ” are created equal. Many are simply middlemen who outsource to larger factories, leading to quality inconsistencies. To find a true partner, use this checklist:

- In-House Capabilities: Does the factory have its own CAD designers and casting equipment? A true small batch jewelry partner should control the process from start to finish.

- Turnaround Time: In the small batch world, speed is key. Look for partners who offer a 7-14 day production window.

- Sample Quality: Always order a single sample before committing to a 30-piece run. Check for stone security, plating thickness, and metal purity.

- Communication: Small batch production requires more back-and-forth than bulk orders. Ensure your manufacturer has a dedicated account manager who understands your brand’s aesthetic.

At HonHo Jewelry, we pride ourselves on being a transparent partner for brands looking to scale through the small batch jewelry model.

V. Frequently Asked Questions (FAQs)

1. Is the per-unit cost higher for small batch jewelry?

Yes, typically the per-unit cost is slightly higher than mass production because the setup costs are spread over fewer pieces. However, when you factor in the savings from not having dead stock and lower storage costs, the “total cost of business” is often much lower with small batch jewelry.

2. What is the typical MOQ for a small batch?

While it varies by factory, a typical small batch jewelry MOQ is between 10 and 50 pieces per style. Some specialized manufacturers may even offer as low as 5 pieces for high-end gold or platinum designs.

3. Can I use custom gemstones in small batches?

Absolutely. One of the benefits of small batch jewelry is the ability to use unique, ethically sourced, or even lab-grown gemstones that might be difficult to source in quantities of 1,000+.

4. How do I protect my designs when working with a manufacturer?

Always sign a Non-Disclosure Agreement (NDA) before sharing your CAD files. A reputable small batch jewelry manufacturer will respect your intellectual property and won’t sell your designs to other clients.

5. Is small batch jewelry suitable for high-end luxury brands?

Yes. Many luxury brands use small batch jewelry production for limited edition releases or to test new “avant-garde” designs before committing to a full collection.

6. What materials are best for small batch production?

925 Sterling Silver, 14K/18K Gold, and Brass are the most common materials. Silver is particularly popular for small batch jewelry because of its lower material cost and high perceived value.

7. How long does the small batch process take?

From CAD approval to final delivery, the process usually takes 2 to 4 weeks. This is significantly faster than the 2-3 months required for traditional mass production.

8. Can I get custom packaging for small batches?

Yes, many manufacturers now offer low MOQ custom packaging (boxes, pouches, and tags) to ensure your small batch jewelry arrives with a premium brand experience.

Conclusion: Start Small, Scale Smart

The future of the jewelry industry belongs to the agile. By embracing small batch jewelry manufacturing, you are not just reducing your risk; you are building a brand that can adapt, innovate, and grow in harmony with modern consumer values.

Ready to launch your next collection with a partner who understands the power of Low MOQ? Contact Dongguan HonHo Jewelry today and let’s bring your vision to life, one small batch at a time.

References

[1] ISO.org – Quality Management Systems

[2] CPSC – Small Batch Manufacturer Definition

[3] GIA – Jewelry Industry Trends 2026

[4] Responsible Jewellery Council – Sustainability Standards

[5] Forbes – The Rise of Micro-Collections in Fashion

share this recipe:

Still hungry? Here’s more

How to Dodge Jewelry Sourcing Risks from China: Your 2026 Playbook

The allure of jewelry sourcing from China is undeniable. It’s a global hub of manufacturing,

Top 50 Jewelry Brands Worth to Buy 2026: The Definitive Investment & Style Encyclopedia

The global jewelry market in 2026 is a fascinating landscape where centuries-old heritage meets cutting-edge

Why Brass Jewelry Wholesale Fits Fashion Brands: The Strategic Guide for 2026

In the rapidly evolving landscape of the global fashion industry, the demand for affordable luxury

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.