7 Best Titanium Jewelry Manufacturers in 2026: Expert Guide

In recent years, the demand for titanium jewelry has skyrocketed, and for good reason. This remarkable metal, once reserved for aerospace and medical applications, has found its place in the world of fashion, offering an unparalleled combination of strength, lightness, and biocompatibility.

As more consumers seek durable, stylish, and skin-friendly accessories, the market for titanium jewelry is expected to continue its upward trend. However, not all titanium jewelry is created equal, and finding a reliable titanium jewelry manufacturer can be a daunting task.

This guide is here to help. We will explore the top 7 titanium jewelry manufacturers in 2026, diving deep into what makes each of them stand out. From cutting-edge manufacturing processes to innovative designs, you will gain a comprehensive understanding of the industry’s best. Whether you are a jewelry brand looking for a wholesale supplier or a consumer seeking the perfect custom piece, this article will provide you with the knowledge to make an informed decision.

We will also cover the essential aspects of titanium jewelry, including its benefits, manufacturing techniques, and how to choose the right partner for your needs. With over 15 years of experience in custom jewelry manufacturing, we at HonHo Jewelry are excited to share our insights and help you navigate this thriving market.

1. HonHo Jewelry (Dongguan, China)

As a leading titanium jewelry manufacturer based in China, HonHo Jewelry has established a strong reputation for quality, innovation, and customer-centric services. With over 15 years of experience in the industry, HonHo Jewelry combines traditional craftsmanship with modern technology to produce exquisite custom jewelry for a global clientele. Their commitment to excellence is evident in every piece they create, making them a top choice for brands seeking a reliable and versatile manufacturing partner.

One of HonHo Jewelry’s most significant advantages is its in-house PVD (Physical Vapor Deposition) vacuum plating facility. This advanced technology allows for the application of a durable and long-lasting coating on titanium jewelry, enhancing its resistance to wear and tear. They specialize in using a titanium nitride (TiN) coating, which not only provides a beautiful finish but also makes the jewelry waterproof and non-tarnish. This is a key differentiator in the market, as it ensures that the jewelry maintains its appearance even with daily wear. In fact, HonHo Jewelry is so confident in the quality of their plating that they offer a 24-month warranty, a testament to their commitment to durability.

HonHo Jewelry’s dedication to customization is another reason why they are a preferred partner for many brands. With a team of five in-house designers, they can transform any concept into a market-ready product. They offer flexible minimum order quantities, making them accessible to both emerging and established brands. Their rigorous quality control process, which ensures a defect rate of less than 0.5%, guarantees that every piece meets the highest standards. By focusing on sustainable and recyclable materials, HonHo Jewelry not only creates beautiful jewelry but also demonstrates a commitment to ethical and environmentally friendly practices.

2. NeoMetal Inc (California, USA)

NeoMetal Inc. is a name that resonates with quality and innovation in the body piercing industry. Based in California, this titanium jewelry manufacturer has been a pioneer since the early 90s, and their influence on the market is undeniable. They are the original creators of the threadless body jewelry system, a revolutionary design that has become a standard in the industry. This innovation alone speaks volumes about their commitment to improving the piercing experience for both piercers and clients.

NeoMetal’s dedication to quality is backed by their ISO 9001:2015 certification, a globally recognized standard for quality management systems. This certification ensures that their manufacturing processes are consistently monitored and improved to meet the highest standards. They use ASTM F-136 certified implant-grade titanium, which is a hypoallergenic and biocompatible material, making their jewelry safe for new and healed piercings. This focus on safety and quality has made them a trusted choice for professional piercers worldwide.

With over 30 years of history, NeoMetal has built a strong brand authority. Their jewelry is handcrafted in their California shop, and they take pride in their American-made products. While they specialize in body piercing jewelry, their expertise in working with titanium is a valuable resource for anyone interested in high-quality titanium products. Their content strategy focuses on their manufacturing process, history, and the innovation behind their threadless system, providing a wealth of information for those looking to understand the technical aspects of titanium jewelry.

3. TriTech Titanium Parts (Michigan, USA)

TriTech Titanium Parts stands out as a highly specialized titanium jewelry manufacturer with a strong focus on the technical aspects of production. Based in Michigan, they offer a unique approach by providing three distinct manufacturing processes: 3D printing (binder jetting), investment casting, and metal injection molding. This versatility allows them to cater to a wide range of needs, from complex prototypes to large-scale production runs, making them a valuable partner for businesses with specific technical requirements.

Their expertise in multiple manufacturing methods is a significant advantage. While many manufacturers specialize in a single process, TriTech’s ability to offer a range of options ensures that clients receive the most efficient and effective solution for their projects. Their team of experts guides clients through the selection process, helping them choose the best method based on factors like part complexity, volume, and cost. This collaborative approach is a key part of their service, as they work closely with clients from the initial design phase to optimize for manufacturability.

TriTech’s content is heavily focused on education, with a detailed FAQ section that addresses common questions about titanium part manufacturing. This demonstrates their commitment to transparency and their desire to empower clients with knowledge. While their primary focus is on B2B services for various industries, their expertise in titanium manufacturing is highly relevant to the jewelry market. For brands looking to create intricate and technically demanding designs, TriTech’s advanced capabilities and collaborative approach make them a top contender.

4. Anatometal (California, USA)

When it comes to premium, handcrafted body jewelry, Anatometal is a name that commands respect. This California-based titanium jewelry manufacturer has been setting the standard for quality and craftsmanship since 1991. Their commitment to excellence is evident in every piece they produce, all of which are made in-house from implant-grade materials and meticulously hand-polished to a flawless finish. This dedication to quality has earned them a loyal following among professional piercers and jewelry enthusiasts alike.

Anatometal’s focus on customization is a key aspect of their brand. They offer a wide range of materials, gemstones, and finishes, allowing clients to create truly unique pieces. Their extensive gemstone catalog is particularly impressive, featuring a stunning array of options to suit any style. This commitment to personalization, combined with their high-quality materials, makes them a top choice for those seeking bespoke titanium jewelry.

With over 30 years in the industry, Anatometal has established strong partnerships with studios worldwide. Their content strategy reflects their premium positioning, with a focus on craftsmanship, customization, and the quality of their materials. They are a great example of a brand that has built its reputation on a foundation of quality and artistry, making them a benchmark for excellence in the titanium jewelry market.

5. Titanium Rings (Canada)

For those in search of custom-crafted titanium rings and wedding bands, Titanium Rings is a leading North American titanium jewelry manufacturer with over 20 years of experience. What sets them apart is their made-to-order approach, ensuring that every ring is a unique creation tailored to the customer’s specifications. They use medical-grade 6-4 ELI titanium, a high-quality alloy known for its strength and biocompatibility, making their rings both durable and safe for sensitive skin.

One of the most compelling aspects of Titanium Rings is their lifetime warranty, which speaks to the confidence they have in their products. This, combined with their extensive experience, has made them a trusted name in the online jewelry market. Their website features a vast catalog of designs, from classic bands to intricate custom creations, providing ample inspiration for customers. They also offer a wealth of information on their blog, covering topics from ring sizing to the benefits of titanium, further establishing their authority in the field.

Titanium Rings’ focus on customization and quality has earned them a strong reputation. Their commitment to using high-quality materials and their made-to-order process ensure that every customer receives a product that is both beautiful and built to last. For those specifically looking for titanium rings, their specialization and experience make them a top choice.

6. Diablo Body Jewelry (USA)

Diablo Body Jewelry is another prominent American titanium jewelry manufacturer that has carved out a niche in the body piercing community. They are known for their high-quality, implant-grade titanium jewelry, which is a preferred choice for professional piercers. Their commitment to using safe and durable materials has made them a trusted name in the industry, and their products are a staple in many piercing studios.

Diablo Body Jewelry offers a wide range of products, including threadless ends, circular barbells, and septum jewelry. Their focus on body jewelry means that they have a deep understanding of the specific needs of this market, from the importance of biocompatibility to the need for secure and comfortable designs. Their American-made products are a testament to their commitment to quality and craftsmanship.

While their website is primarily a retail platform, it provides a good overview of their product offerings and their focus on quality. For those in the body piercing industry, Diablo Body Jewelry is a well-respected and reliable source for high-quality titanium jewelry.

7. Grayling Jewelry (USA)

Grayling Jewelry is a US-based titanium jewelry manufacturer that has made a name for itself by focusing on hypoallergenic and lightweight designs. They exclusively use F-136 implant-grade titanium, ensuring that their jewelry is safe for even the most sensitive skin. This commitment to quality and safety has made them a popular choice for those who have struggled with metal allergies.

Grayling’s designs are known for their comfort and durability. They emphasize that their jewelry is corrosion-resistant and will not tarnish, making it ideal for everyday wear. Their premium positioning is reflected in their clean and modern aesthetic, which appeals to a discerning clientele. While their product range is more focused on fashion-forward designs, their expertise in working with titanium is evident in the quality of their products.

For consumers who prioritize hypoallergenic properties and stylish designs, Grayling Jewelry is an excellent choice. Their focus on implant-grade titanium and their commitment to quality make them a trusted source for safe and beautiful jewelry.

Understanding Titanium Jewelry Manufacturing

Titanium jewelry manufacturing is a complex and fascinating process that combines artistry with advanced engineering. Unlike traditional jewelry metals like gold and silver, titanium is a reactive metal, which means it requires special handling and a controlled environment to be worked effectively. The manufacturing process is not just about shaping the metal; it’s about understanding its unique properties and leveraging them to create pieces that are both beautiful and incredibly durable.

At its core, the process begins with high-quality titanium, often in the form of rods or sheets. The grade of titanium is crucial, with ASTM F-136 being the standard for implant-grade titanium used in high-quality body jewelry [1]. This specific grade is chosen for its biocompatibility, meaning it is non-toxic and does not cause allergic reactions, making it ideal for direct contact with the skin. The manufacturing process itself can vary depending on the desired outcome, but it generally involves a combination of precision machining, casting, and finishing techniques.

Quality standards are paramount in titanium jewelry manufacturing. Reputable manufacturers often adhere to strict quality control protocols, such as the ISO 9001:2015 standard, which ensures that every stage of the production process is carefully monitored and documented. This commitment to quality is what separates a high-end piece of titanium jewelry from a mass-produced item. It’s the attention to detail, the precision of the machining, and the flawlessness of the finish that define a truly exceptional piece.

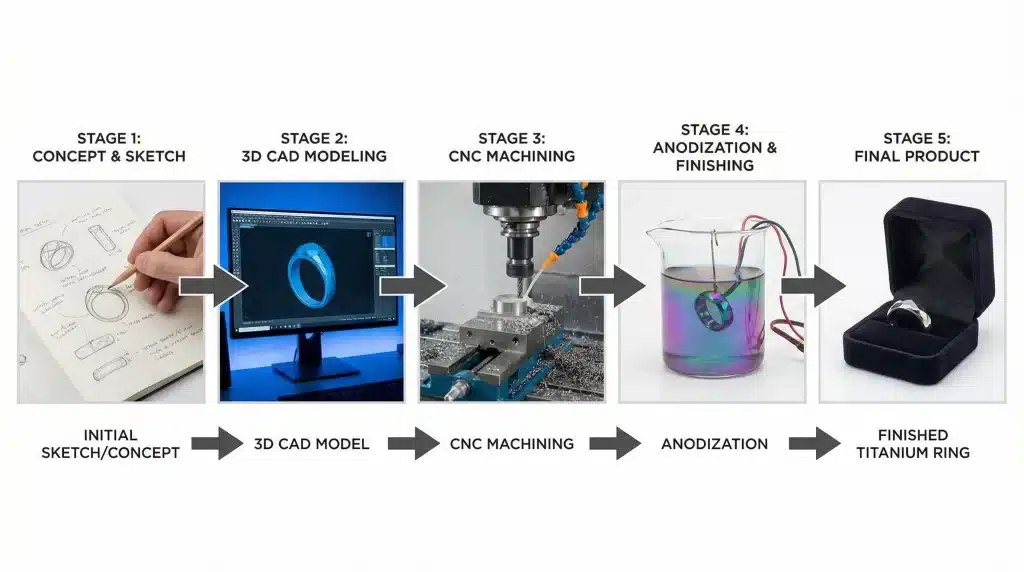

Key Manufacturing Processes

The creation of titanium jewelry involves a variety of sophisticated manufacturing processes, each with its own unique advantages. A skilled titanium jewelry manufacturer will often employ a combination of these techniques to achieve the desired design and quality. Here are some of the key processes used in the industry:

CNC Machining

CNC (Computer Numerical Control) machining is a cornerstone of modern titanium jewelry manufacturing. This process uses computer-controlled machines to cut and shape titanium with incredible precision. As seen in the manufacturing of high-end titanium bracelets, CNC machining allows for the creation of intricate designs and complex geometries that would be impossible to achieve by hand [2]. The process is programmed using CAM (Computer-Aided Manufacturing) software, which translates a 3D design into a set of instructions for the machine. This level of precision is essential for creating high-quality, consistent products.

3D Printing (Binder Jetting)

3D printing, specifically binder jetting, is an emerging technology in titanium jewelry manufacturing. This process builds up a part layer by layer from a powdered titanium material, which is then sintered in a furnace to create a solid piece. As highlighted by manufacturers like TriTech Titanium, 3D printing is ideal for creating complex prototypes and custom designs with a quick turnaround time. It allows for a level of design freedom that is not possible with traditional manufacturing methods, making it a valuable tool for innovation.

Investment Casting

Investment casting, also known as lost-wax casting, is a more traditional method that has been adapted for titanium. In this process, a wax model of the jewelry piece is created and then coated in a ceramic material. The wax is then melted out, leaving a ceramic mold that is filled with molten titanium. This method is well-suited for creating larger and more complex shapes, but it requires a high level of expertise due to titanium’s reactive nature.

Anodization for Color

One of the most exciting aspects of titanium jewelry is the ability to add vibrant colors through a process called anodization. As demonstrated in various video tutorials, this is not a paint or a coating, but an electrochemical process that alters the oxide layer on the surface of the titanium [3]. By varying the voltage applied during the process, a wide spectrum of colors can be achieved, from rose gold and pink to purple and green. This allows for a high degree of customization and creativity in jewelry design.

PVD Plating for Durability

Physical Vapor Deposition (PVD) is another advanced coating technology used to enhance the durability and appearance of titanium jewelry. This process involves depositing a thin layer of a hard material, such as titanium nitride (TiN), onto the surface of the jewelry in a vacuum chamber. This creates a finish that is not only beautiful but also incredibly resistant to scratches, corrosion, and tarnishing. Manufacturers like HonHo Jewelry specialize in this technology, offering a 24-month warranty on their PVD-plated products.

Why Titanium Jewelry Stands Out

Titanium has quickly become a favored material in the jewelry industry, and for good reason. Its unique combination of properties sets it apart from traditional metals, offering a range of benefits that appeal to modern consumers. A reputable titanium jewelry manufacturer will leverage these properties to create pieces that are not only beautiful but also incredibly practical for everyday wear.

One of the most significant advantages of titanium is its hypoallergenic nature. Many people suffer from metal allergies, particularly to nickel, which is a common component in many jewelry alloys. Implant-grade titanium, such as ASTM F-136, is completely nickel-free, making it a safe and comfortable choice for those with sensitive skin [4]. This biocompatibility is why titanium is also widely used in medical implants, a testament to its safety.

In addition to being skin-friendly, titanium is also incredibly durable and lightweight. It is as strong as steel but 45% lighter, making it comfortable to wear all day, every day. It is also highly resistant to bending, cracking, and scratching, ensuring that your jewelry will maintain its shape and beauty for years to come. This durability, combined with its resistance to corrosion and tarnishing, makes titanium a low-maintenance option that is perfect for an active lifestyle.

Another exciting feature of titanium is its ability to be colored through anodization. This process allows for a wide range of vibrant and unique colors, offering a level of customization that is not possible with many other metals. Furthermore, advanced coating technologies like PVD with titanium nitride (TiN) can provide a waterproof and non-tarnish finish, further enhancing the longevity and appeal of the jewelry. It is this combination of strength, lightness, safety, and versatility that makes titanium jewelry truly stand out in a crowded market.

How to Choose a Titanium Jewelry Manufacturer

Selecting the right titanium jewelry manufacturer is a critical decision that can significantly impact the quality and success of your jewelry line. With so many options available, it’s important to know what to look for to ensure you’re partnering with a reliable and capable manufacturer. Here are some key factors to consider:

Certifications and Quality Standards

First and foremost, look for a manufacturer that adheres to recognized quality standards. Certifications such as ISO 9001:2015 indicate a commitment to quality management, while the use of ASTM F-136 implant-grade titanium is a must for body jewelry and for those with sensitive skin [1]. These certifications are a clear indicator that the manufacturer takes quality and safety seriously.

Manufacturing Capabilities

Consider the manufacturer’s technical capabilities. Do they offer a range of manufacturing processes, such as CNC machining, 3D printing, or investment casting? A manufacturer with diverse capabilities is more likely to be able to meet your specific design needs. Also, inquire about their finishing and coating technologies, such as PVD plating, which can significantly enhance the durability and appearance of the jewelry.

Customization and Design Services

If you’re looking to create custom pieces, it’s essential to partner with a manufacturer that offers robust design services. Look for a company with an in-house design team that can help you bring your vision to life. A good manufacturer will work with you from the initial concept to the final product, providing guidance and expertise along the way. HonHo Jewelry’s custom design services are a great example of this collaborative approach.

Warranty and Customer Support

A manufacturer’s warranty is a strong indicator of their confidence in their products. A 24-month warranty on plating, for example, is a significant selling point. Additionally, consider the level of customer support they provide. A responsive and helpful team can make the entire process much smoother.

Minimum Order Quantities (MOQs)

For new and emerging brands, flexible MOQs are crucial. A manufacturer that is willing to work with smaller order quantities can be a great partner for growth. This allows you to test new designs and manage your inventory more effectively.

By carefully evaluating these factors, you can find a titanium jewelry manufacturer that is the right fit for your brand and your customers. Don’t be afraid to ask questions and do your research – the right partner can make all the difference.

Titanium Jewelry Care & Maintenance

One of the many appeals of titanium jewelry is its low-maintenance nature. However, a little care can go a long way in keeping your pieces looking their best. Unlike other metals, titanium does not tarnish or corrode, but it can accumulate dirt and oils from daily wear. Here are some simple tips for maintaining your titanium jewelry:

For general cleaning, a soft cloth and a mild soap solution are all you need. Simply mix a few drops of mild dish soap with warm water, and gently wipe the jewelry with a soft cloth. Rinse with clean water and dry thoroughly with another soft cloth. For more intricate designs or hard-to-reach areas, a soft-bristled toothbrush can be used. It’s important to avoid harsh chemicals or abrasive cleaners, as these can damage the surface of the jewelry, especially if it has a colored anodized finish.

When it comes to storage, it’s best to keep your titanium jewelry in a separate pouch or compartment in your jewelry box. While titanium is very scratch-resistant, it’s not completely scratch-proof. Storing it separately will prevent it from being scratched by harder gemstones or other metals. With proper care, your titanium jewelry will maintain its beauty and luster for a lifetime.

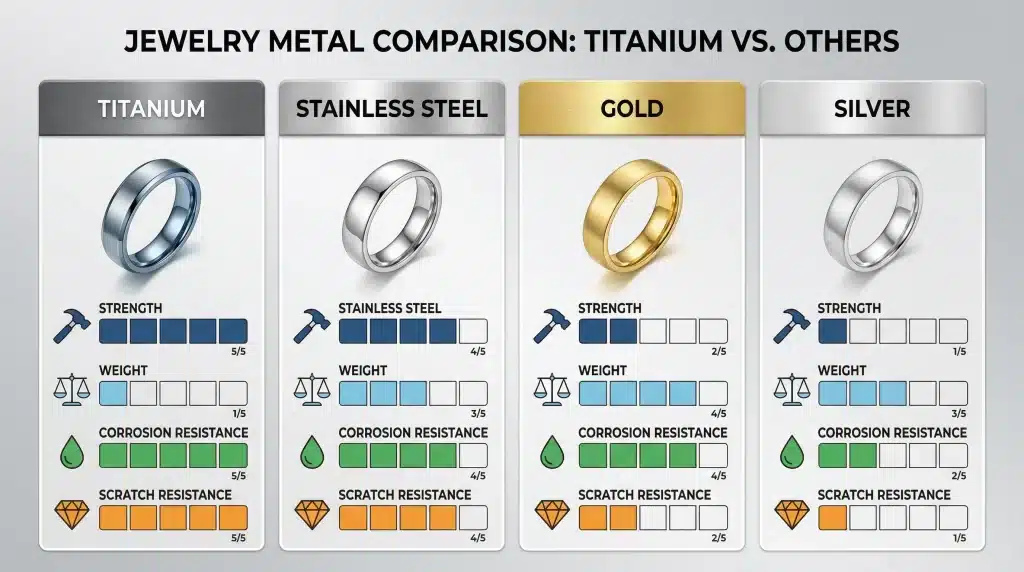

Titanium vs. Other Jewelry Materials

When choosing jewelry, it’s helpful to understand how different materials compare. Here’s a quick look at how titanium stacks up against other popular choices:

| Feature | Titanium | Stainless Steel | Gold | Silver |

|---|---|---|---|---|

| Hypoallergenic | Excellent (Nickel-Free) | Good (Low Nickel) | Varies (Alloys) | Varies (Alloys) |

| Durability | Excellent | Very Good | Good | Fair |

| Weight | Very Lightweight | Heavy | Heavy | Medium |

| Corrosion Resistance | Excellent | Very Good | Excellent | Fair (Tarnishes) |

| Color Options | Wide (Anodization) | Limited | Yellow, White, Rose | Silver |

| Cost | Moderate | Low | High | Moderate |

As the table shows, titanium offers a superior combination of being hypoallergenic, durable, and lightweight. While gold and silver have their classic appeal, they are softer and more prone to damage. Stainless steel is a durable and affordable option, but it is much heavier than titanium and can still contain small amounts of nickel. For those with sensitive skin or an active lifestyle, titanium is often the ideal choice.

Future Trends in Titanium Jewelry Manufacturing

The world of titanium jewelry is constantly evolving, with new technologies and trends emerging all the time. A forward-thinking titanium jewelry manufacturer will be at the forefront of these developments, offering innovative solutions to meet the changing demands of the market. Here are some of the key trends to watch:

Sustainable and Ethical Practices

As consumers become more environmentally conscious, the demand for sustainable and ethically produced jewelry is on the rise. This includes the use of recycled materials, responsible sourcing, and eco-friendly manufacturing processes. Manufacturers who prioritize sustainability will not only appeal to a growing segment of the market but also contribute to a more responsible industry.

Advanced Coating Technologies

The development of new coating technologies is another exciting area of innovation. While PVD and anodization are already well-established, research is ongoing to create even more durable and versatile coatings. These advancements will lead to new color options, improved scratch resistance, and enhanced longevity.

Customization and Personalization

The trend towards personalization is showing no signs of slowing down. Consumers are increasingly looking for unique pieces that reflect their individual style. Manufacturers who can offer a high degree of customization, from intricate designs to personalized engravings, will have a significant advantage in the market.

3D Printing Advancements

As 3D printing technology continues to mature, it will play an increasingly important role in titanium jewelry manufacturing. This technology allows for the creation of complex and intricate designs that would be impossible to produce with traditional methods. As the cost of 3D printing decreases, it will become a more accessible and widely used tool for both prototyping and production.

Conclusion

Choosing the right titanium jewelry manufacturer is a crucial step in creating a successful jewelry line or finding the perfect piece for your personal collection. As we have seen, the top manufacturers in the industry distinguish themselves through their commitment to quality, innovation, and customer service. From the pioneering spirit of NeoMetal to the technical expertise of TriTech and the artisanal craftsmanship of Anatometal, each of these companies brings something unique to the table. However, for those seeking a partner that offers a comprehensive range of services, from advanced coating technologies to flexible customization options, HonHo Jewelry stands out as a top contender.

With their in-house PVD plating facility, 24-month warranty, and dedicated design team, HonHo Jewelry is well-equipped to meet the diverse needs of the modern jewelry market. Their focus on quality control and sustainable practices further solidifies their position as a leading manufacturer. Whether you are an established brand or just starting, we encourage you to explore HonHo Jewelry’s stainless steel, brass, and 925 sterling silver collections alongside their titanium offerings, and contact them to discuss your project and discover how they can help you create beautiful, durable, and high-quality jewelry.

References

[1] ASTM International. “Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401).” https://www.astm.org/f0136-13.html

[2] Kieser Design Watches. “Making a High-End Titanium Bracelet – Part 1: Design & Milling.” YouTube, 2 years ago, https://www.youtube.com/watch?v=gkDOmIiGLLc (rel=”nofollow”)

[3] Johnny Stylz. “How to anodize titanium jewelry.” YouTube, 4 years ago, https://www.youtube.com/watch?v=FBm3zg4FBHU (rel=”nofollow”)

[4] Bodyartforms. “What you Need to Know About Titanium Jewelry.” YouTube, 2 years ago, https://www.youtube.com/watch?v=DI4f4Q6FB54 (rel=”nofollow”)

share this recipe:

Still hungry? Here’s more

The Unseen Hero: Why Earring Backings Define Quality Jewelry

Every jewelry brand owner knows the sinking feeling. A customer calls, distraught. They’ve lost one

Choosing the Best Jewelry Stone Setting for Mass Production

Selecting the right jewelry stone setting is one of the most pivotal decisions for any

Best Jewelry Stone Setting for Mass Production | HonHo

Choosing the best jewelry stone setting Choosing the best jewelry stone setting is one of

Ready to Design Your Own Jewelry?

Have an idea in mind or need help shaping it? From sketches to finished pieces, our custom jewelry team will work with you step-by-step to bring your vision to life.